A kind of preparation method of negative electrode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, which can be applied to battery electrodes, circuits, electrical components, etc., and can solve problems such as lithium dendrite formation safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

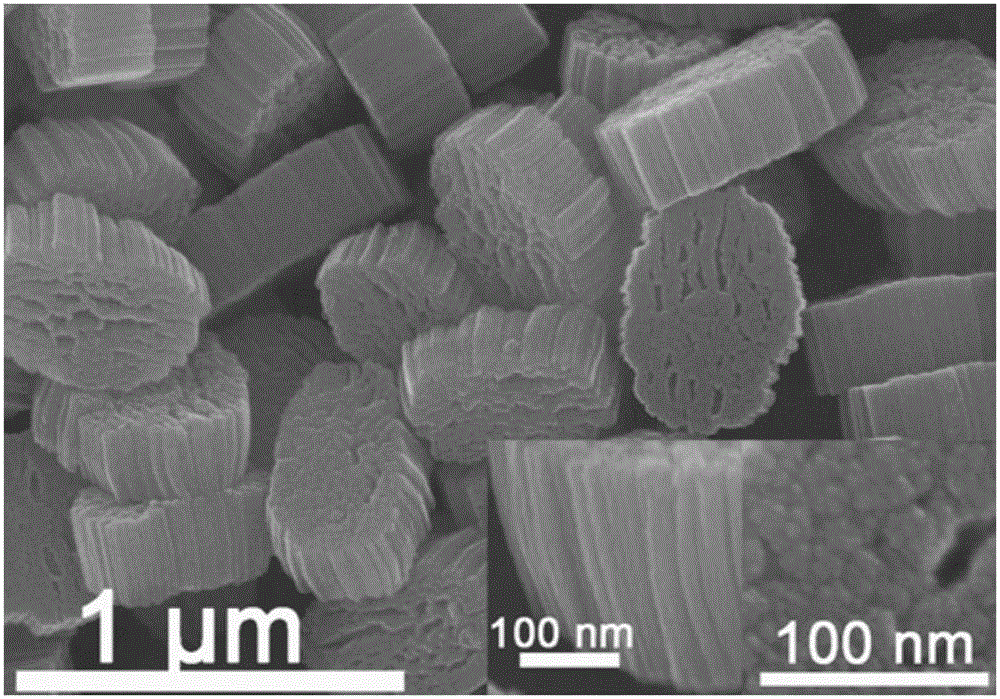

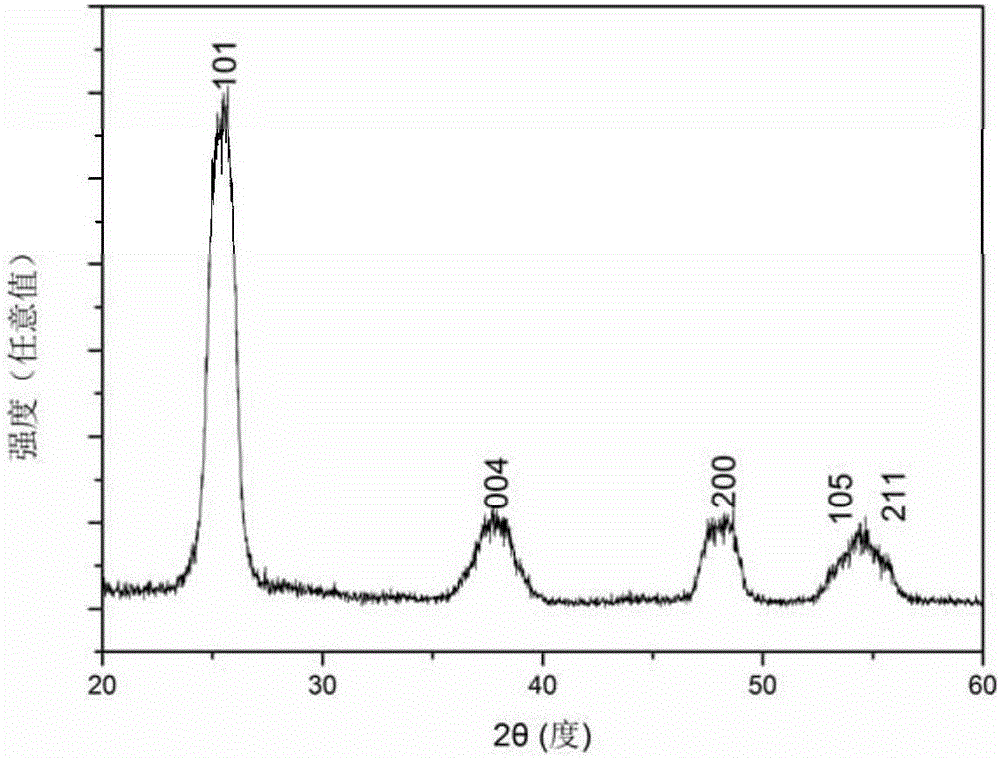

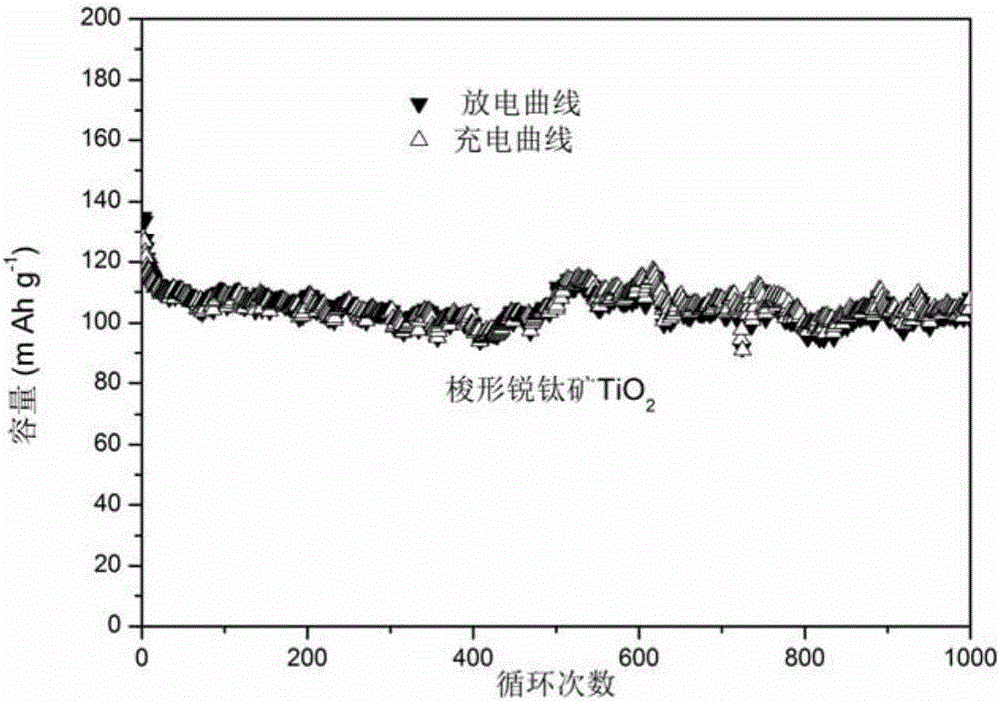

Embodiment 1

[0018] (1) Add 0.5ml of tetrabutyl titanate to 30ml of methanol, stir at room temperature for 12h, transfer the reaction solution to an autoclave, and react at 160°C for 6h. (2) After the autoclave is cooled to room temperature, a white precipitate is obtained by centrifugation and washing, and then the white precipitate is dried.

[0019] (3) Calcining the dried white precipitate at 500°C for 2 hours to prepare a lithium ion battery negative electrode material.

Embodiment 2

[0021] (1) Add 0.5ml of tetrabutyl titanate to 30ml of methanol, stir at room temperature for 12h, transfer the reaction solution to an autoclave, and react at 160°C for 12h.

[0022] (2) After the autoclave is cooled to room temperature, a white precipitate is obtained by centrifugation and alcohol washing. Dry the white precipitate.

[0023] (3) Calcining the dried white precipitate at 500°C for 2 hours to prepare a lithium ion battery negative electrode material.

Embodiment 3

[0025] (1) Add 1ml of tetrabutyl titanate to 30ml of 1,3-propanediol, stir at room temperature for 12h, transfer the reaction solution to an autoclave, and react at 160°C for 24h.

[0026] (2) After the autoclave is cooled to room temperature, a white precipitate is obtained by centrifugation and washing. Dry the white precipitate.

[0027] (3) Calcining the dried white precipitate at 500°C for 2 hours to prepare a lithium ion battery negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com