Technology and device for removing heavy metal ions in electroplating wastewater

A technology for heavy metal ions and electroplating wastewater, which is applied in metallurgical wastewater treatment, separation methods, water/sewage treatment, etc., can solve the problems of metal recycling limitations, difficulty in monitoring and recycling of trace heavy metals, and improve wastewater Effects of throughput, improvement of purity, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

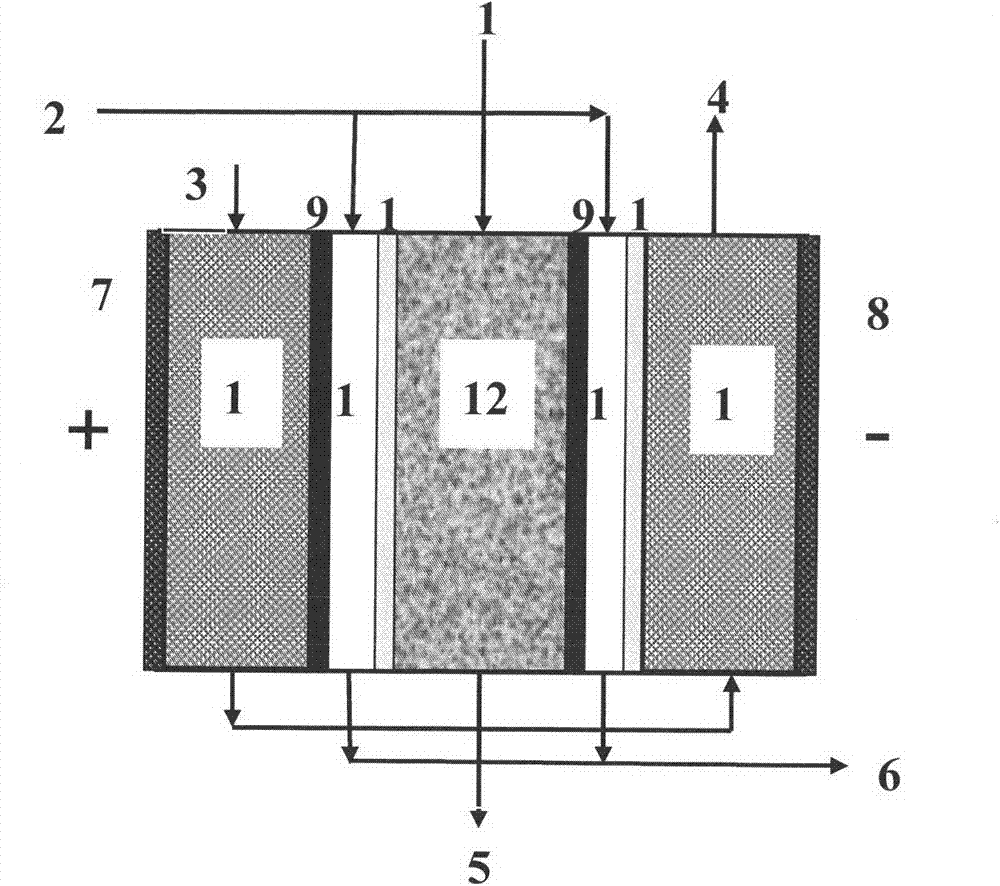

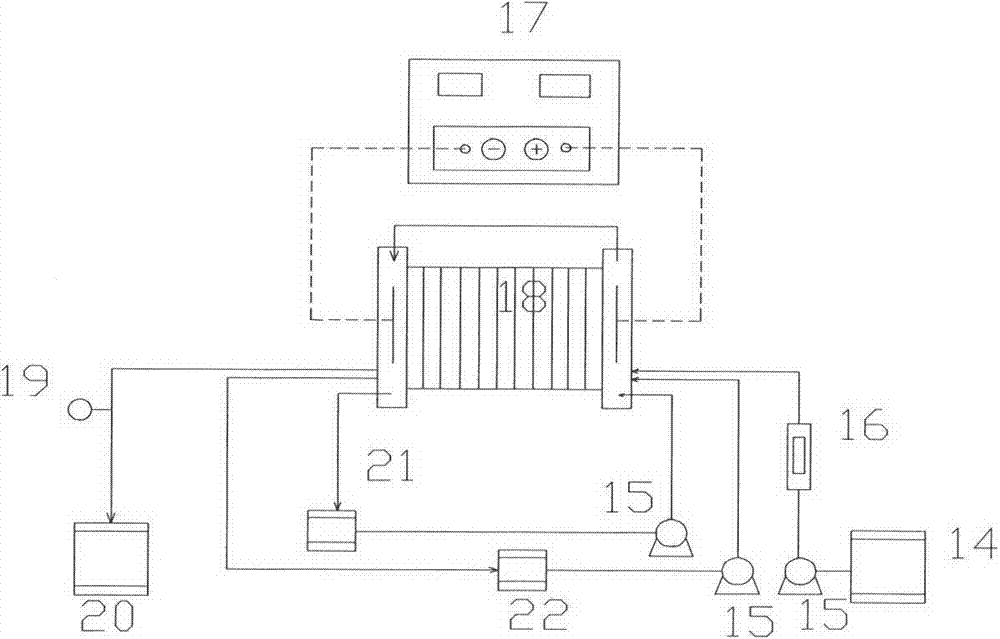

[0024] In this embodiment, the heavy metal ion removal device is a stage, such as figure 1 As shown, there is a desalination chamber, two concentrating chambers and two electrode chambers between the electrodes. The titanium ruthenium-plated electrode is used as the anode, the stainless steel electrode is used as the cathode, and the cathode and anode electrodes are inlaid on the reinforcement plates on both sides for reinforcement. The size of the separator in the desalination chamber and the electrode chamber is 800×250×10mm, the size of the separator in the concentration chamber is 800×250×2mm, the size of the reinforcing plate is 800×250×30mm, and the effective membrane area is 200cm 2 . Both the anion and cation membranes are domestically produced anion and cation exchange membranes, the fibers are domestic anion and cation exchange fibers, and the resin is domestic anion and cation exchange resins. Among them, the proportion of cation exchange fiber in the desalination ...

Embodiment 2

[0026] In this embodiment, the heavy metal ion removal device is similar to that in Embodiment 1. There is a desalination chamber, two concentrating chambers and two electrode chambers between the two electrodes, and carbon fiber cloth is used as the cathode and anode respectively. The dimensions of the desalination chamber partition are 500×200×2mm, the size of the electrode chamber partition is 500×200×3mm, the size of the concentration chamber partition is 500×200×1mm, and the size of the reinforcement plate is 500×200× 25mm effective membrane area is 96cm 2 . The ion exchange membrane used is a domestically produced homogeneous anion-cation exchange membrane, the fiber is a domestically produced anion-cation exchange fiber, and the resin is a domestically produced anion-cation exchange resin. Among them, the proportion of cation exchange fibers in the mixed ion exchange fibers in the desalination chamber is 80%. The raw water entering the desalination chamber is a 1mg / L h...

Embodiment 3

[0028] In this embodiment, the heavy metal ion removal device is the same as in Embodiment 2, and what is changed is that ion exchange resin is filled in the desalination chamber as the ion exchange medium. The ion exchange resin with the same ratio of anion and cation in 2 is operated under the current condition of 150mA. After two hours of operation, the conductivity of the fresh water effluent also drops to 1μS / cm, but the enrichment factor of the concentrated water cycle is about 60 times. , less than the desalination chamber filled with mixed ion exchange fibers as the exchange transfer medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com