Conductive metal interconnection wire and manufacturing method thereof

A technology of conductive metal and conductive metal film, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as the decline in the conductivity of aluminum alloys, and achieve good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

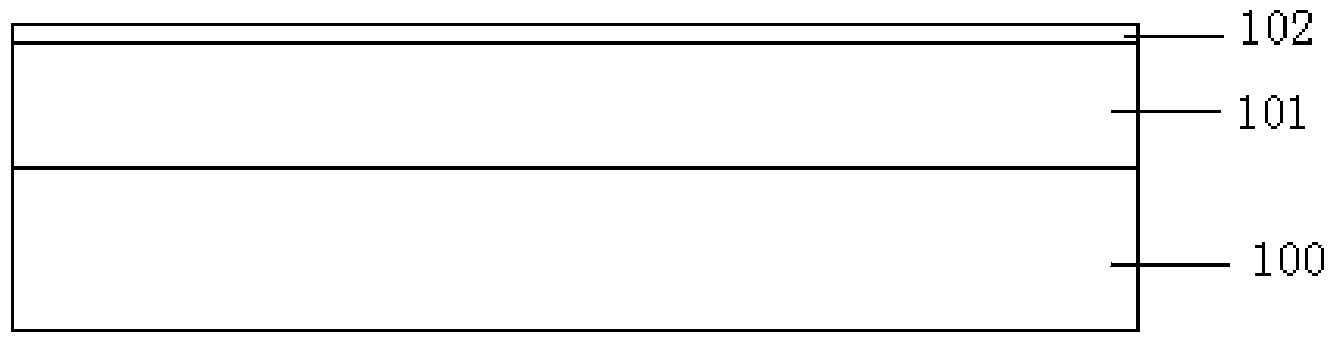

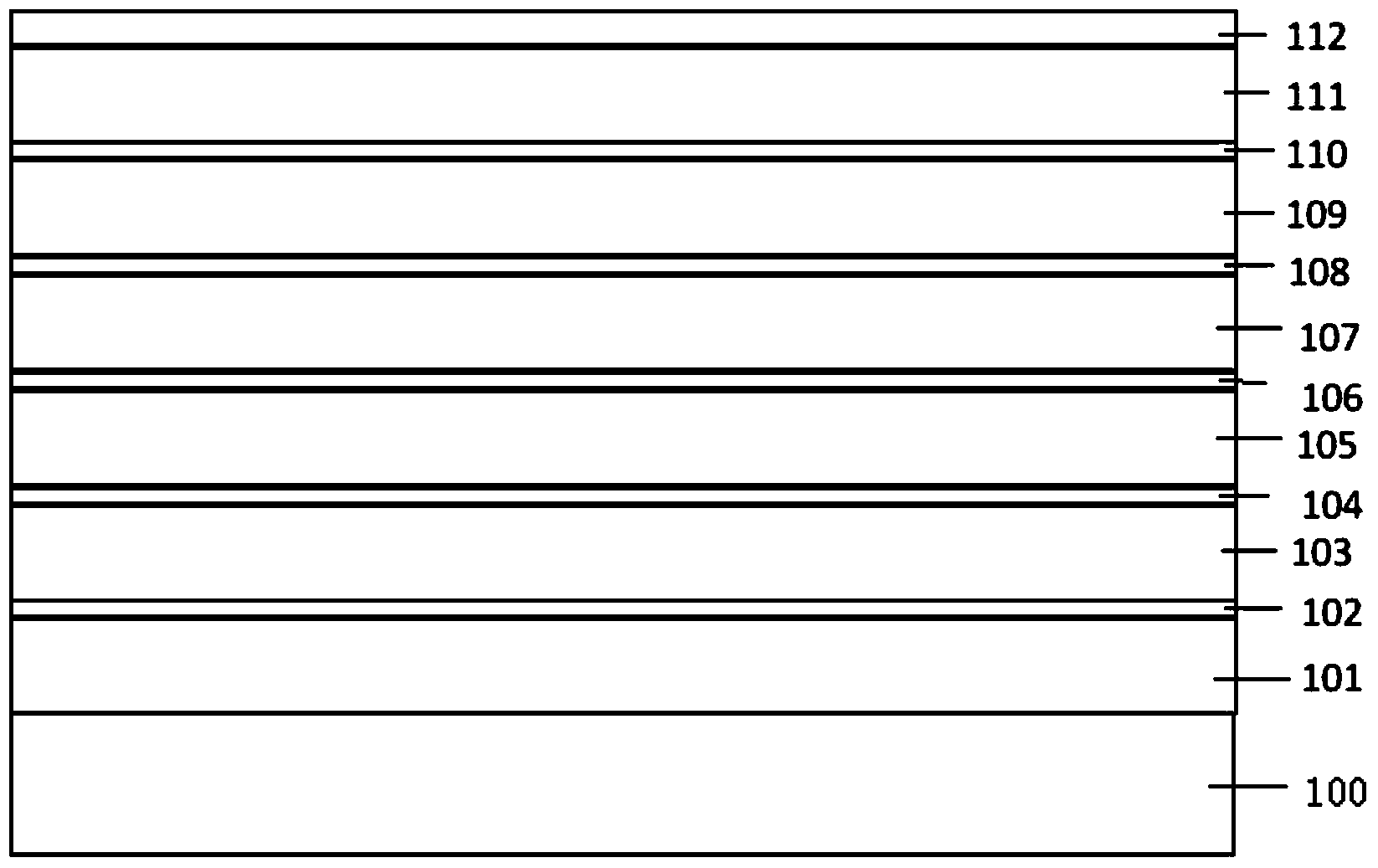

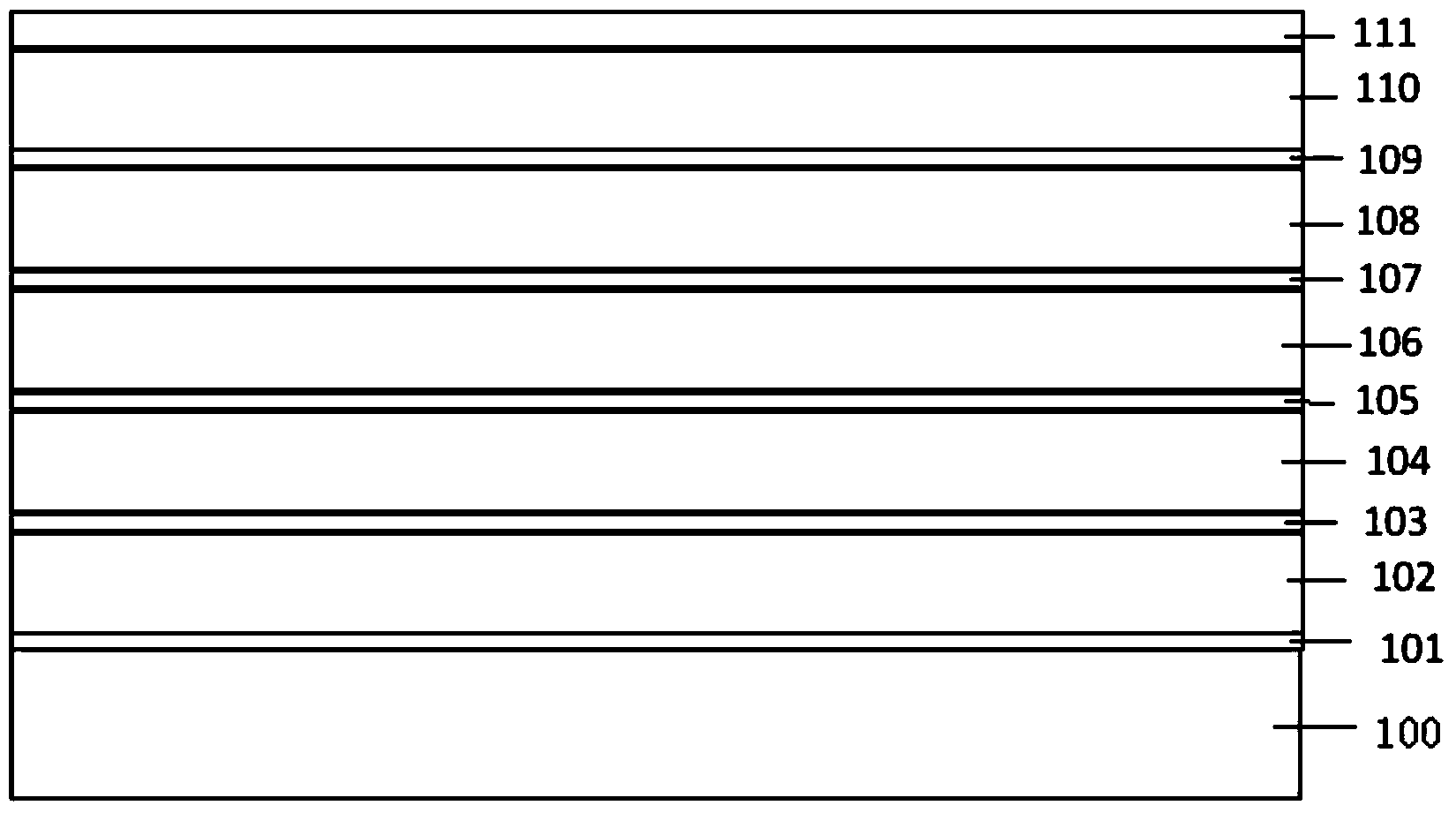

[0024] The invention provides a conductive metal interconnection wire and a preparation method thereof, which can be applied to the backplane of a flat panel display, and can also limit the excessive growth of conductive metal crystal grains, thereby reducing the surface roughness of the entire film layer and improving the thickness of the backplane of the flat panel display. The contact characteristics of each layer of TFT (Thin Film Transistor, Thin Film Field Effect Transistor) prevent the occurrence of short circuit defects. Through the preparation method of the conductive metal interconnection wire provided by the invention, the performance of the manufactured conductive metal interconnection wire can be made to meet the requirements of large-scale production and application.

[0025] In the field of semiconductor display, the resistance of metal interconnection wires used as transmission wires should be as small as possible. To improve the transmission performance of met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com