Shock absorber oil seal with good rebound resilience

A shock absorber oil and resilience technology, applied in the field of shock absorber oil seals, can solve the problems of cold resistance, poor high temperature wear resistance, large permanent compression deformation, etc., and achieve strong weather resistance, long service life and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

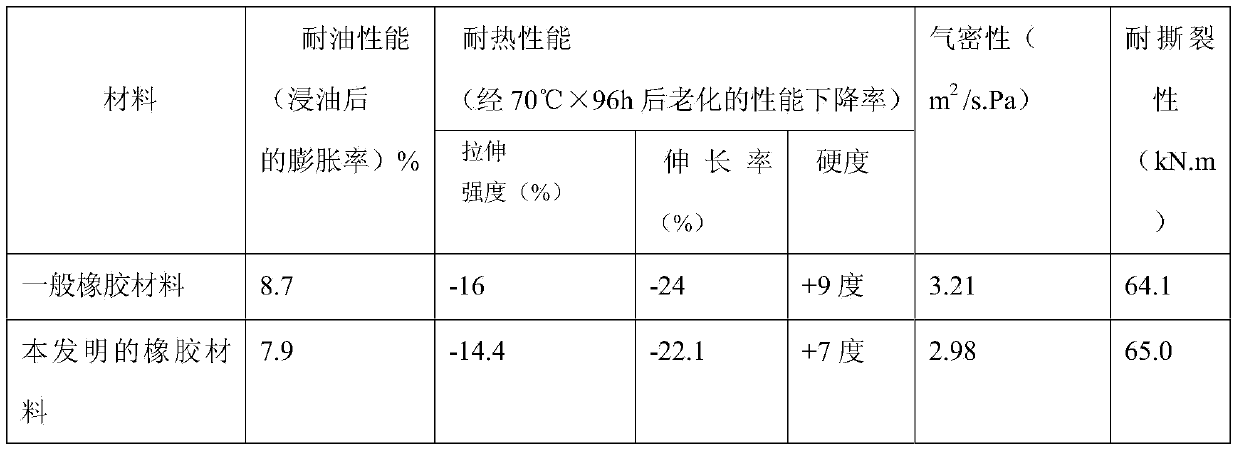

Examples

Embodiment 1

[0015] A shock absorber oil seal with good resilience is composed of the following raw materials in parts by weight (kg):

[0016] Fluorine rubber F26 104, Wannian gray 3, polyethylene glycol 1000 3, dithiosalicylic acid 2, propolis 3, fumed silica 14, monoglyceride stearate 2, SG-3 type PVC resin 8, Absolute ethanol 2, toluene diphenyl phosphate 8, dimethylaminopropylamine 2, magnesium chloride 1, di-tert-butyl peroxide 1, sulfur 0.5, accelerator CZ2, antioxidant 4010 2, composite filler 26;

[0017] Described composite filler is made up of the raw material of following weight part:

[0018] Black soil 40, lithium-based bentonite 10, brominated polystyrene 4, sodium aluminosilicate 3, naphthenic oil 1, zirconium fluoride 0.4, boric acid 0.6;

[0019] Mix the above-mentioned black soil with lithium-based bentonite, calcinate at 700°C for 2 hours, cool and discharge, mix with zirconium fluoride, grind into powder, add brominated polystyrene and naphthenic oil, stir and dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com