Ultrathin high-temperature-resistant thermal insulation material structure

A heat insulation material and high temperature resistant technology, applied in the direction of heat insulation protection pipelines, heat preservation, heat exchange equipment, etc., can solve the problem of reducing the thickness of heat insulation materials, not being able to adapt to the new requirements of heat preservation and heat insulation structures, and ultra-thin heat insulation materials It cannot be directly used as a load-bearing member to achieve the effects of reduced load, excellent overall thermal insulation performance, and light structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

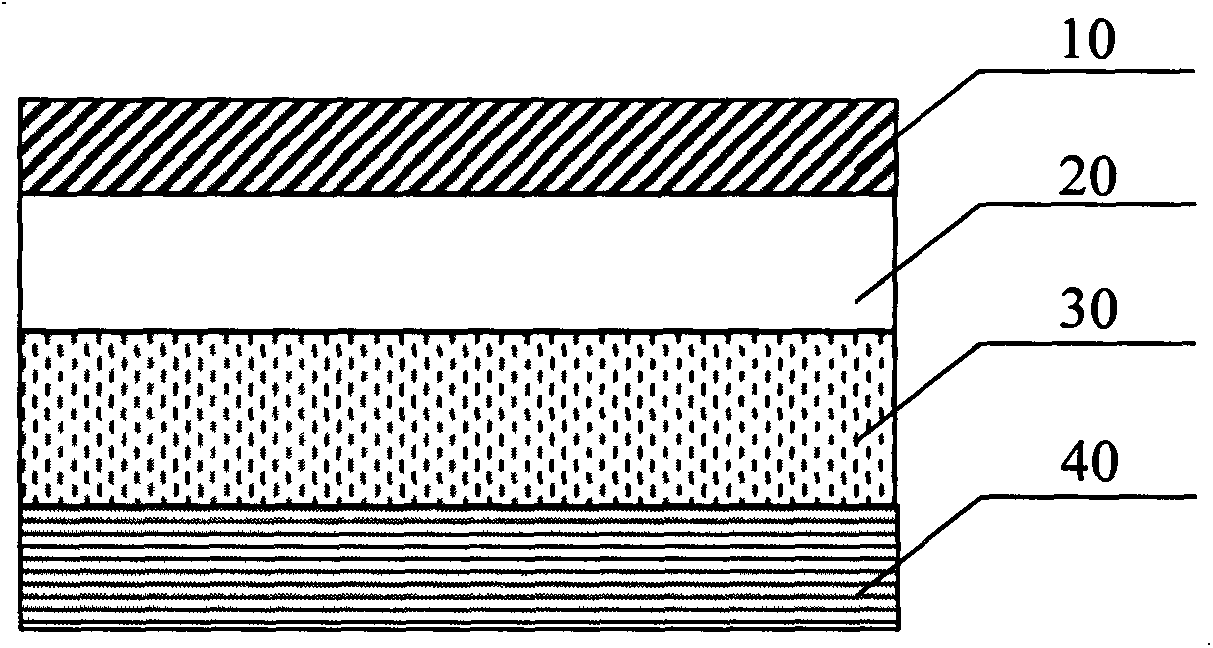

[0017] An ultra-thin heat-resistant and heat-insulating material structure, comprising four laminated layers of an ablation-resistant layer, a high-temperature-resistant layer, a high-temperature heat-insulating layer, and a heat-radiation-resistant layer. The anti-ablation layer is iridium coating; the high-temperature-resistant layer is C / C composite material; the high-temperature insulation layer is composed of stainless steel vacuum-packed ceramic fiber felt, and the thermal conductivity of this layer is 6mW / m K; the heat-resistant radiation layer is made of glass fiber Cloth and aluminum foil are dry-processed, with 5 layers, and the thermal conductivity of this layer is 48mW / m·K; it can be used for high-temperature protection of spacecraft in the temperature range of 1400°C.

Embodiment 2

[0019] An ultra-thin heat-resistant and heat-insulating material structure, comprising four laminated layers of an ablation-resistant layer, a high-temperature-resistant layer, a high-temperature heat-insulating layer, and a heat-radiation-resistant layer. The anti-ablation layer is platinum coating; the high-temperature-resistant layer is C / SiC ceramic matrix composite; the high-temperature insulation layer is composed of stainless steel vacuum-packed ceramic fiber felt, and the thermal conductivity of this layer is 3mW / m K; the heat-resistant radiation layer is composed of It is made of glass fiber cloth and aluminum foil by dry method. The number of layers is 10. The thermal conductivity of this layer is 30mW / m·K, which can be used for high-temperature protection of spacecraft in the temperature range of 1850°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com