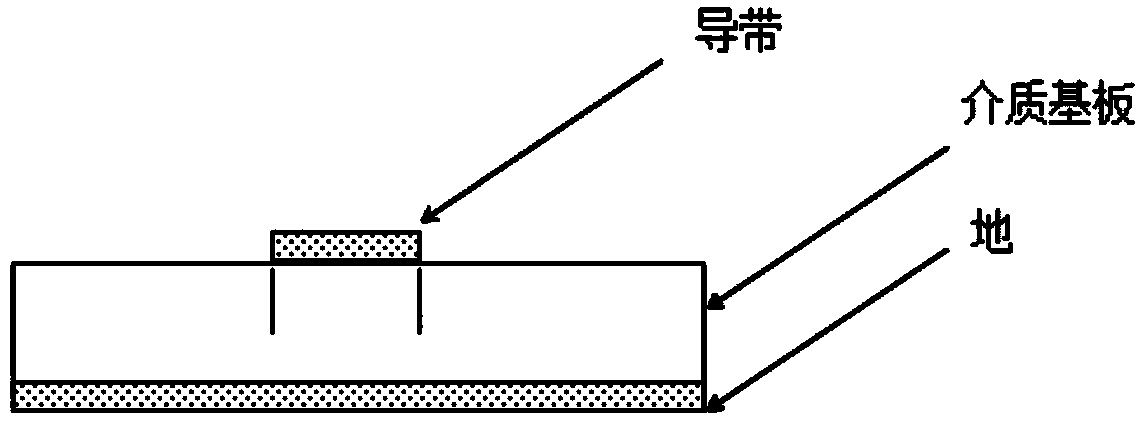

Method for manufacturing high shielding quasi plane transmission line

A fabrication method and quasi-planar technology, applied in electrical components, circuits, waveguide-type devices, etc., can solve the problems of difficult integration, high fabrication cost, radiation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

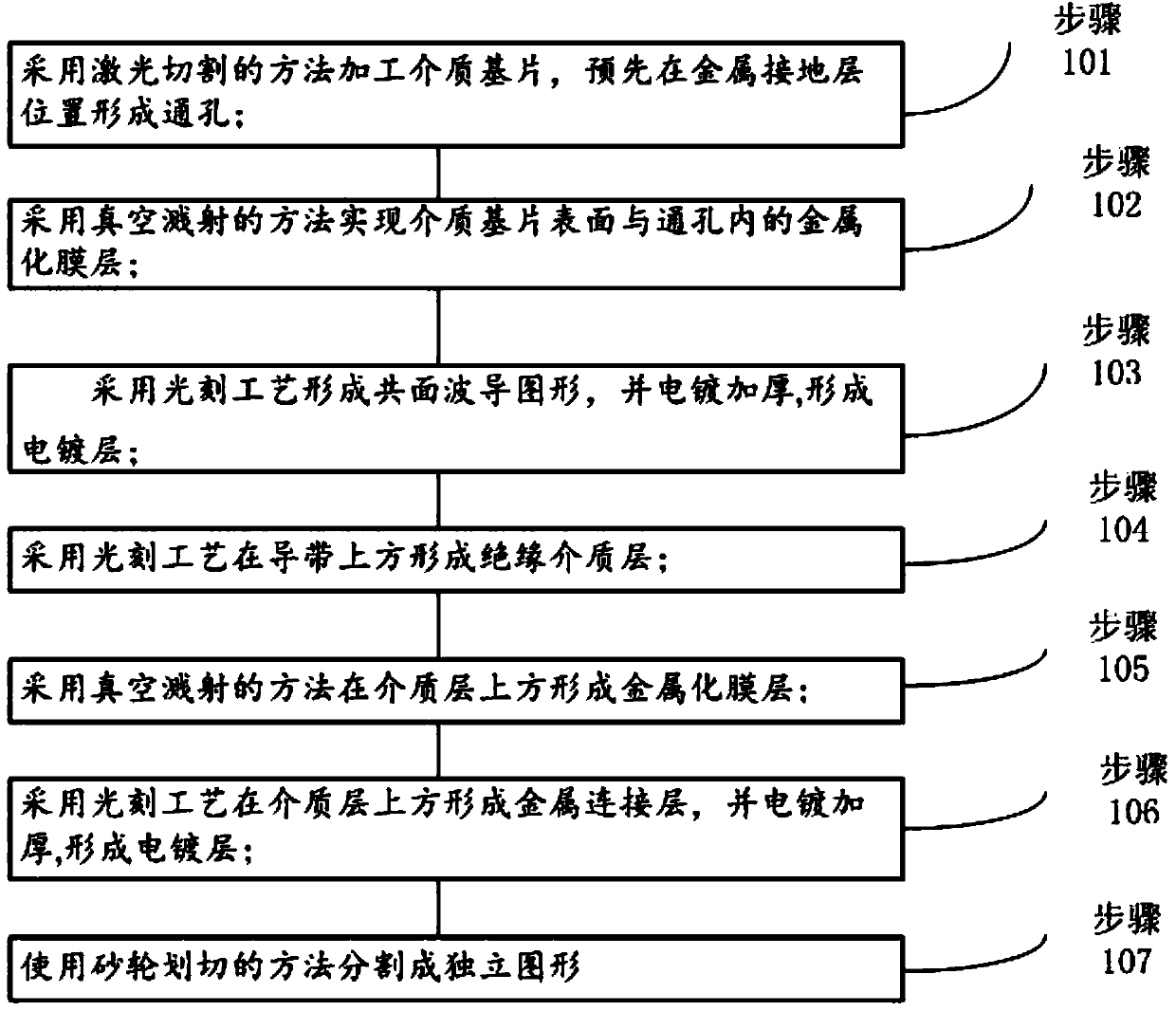

[0036] Such as figure 2 As shown, the flow process of a manufacturing method of a highly shielded quasi-planar transmission line provided by the present invention, the main steps include:

[0037] Step 101, process the dielectric substrate by laser cutting, and form a through hole at the position of the metal ground layer in advance;

[0038] Step 102, implementing metallization on the surface of the dielectric substrate and in the through holes by vacuum sputtering;

[0039] Step 103, using a photolithography process to form a coplanar waveguide pattern, and electroplating to thicken it;

[0040] Step 104, using a photolithography process to form an insulating dielectric layer above the conduction band;

[0041] Step 105, forming a metallization layer on the dielectric layer by vacuum sputtering;

[0042] Step 106, using a photolithography process to form a metal connection layer above the dielectric layer, and electroplating to thicken it;

[0043] Step 107, use the gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com