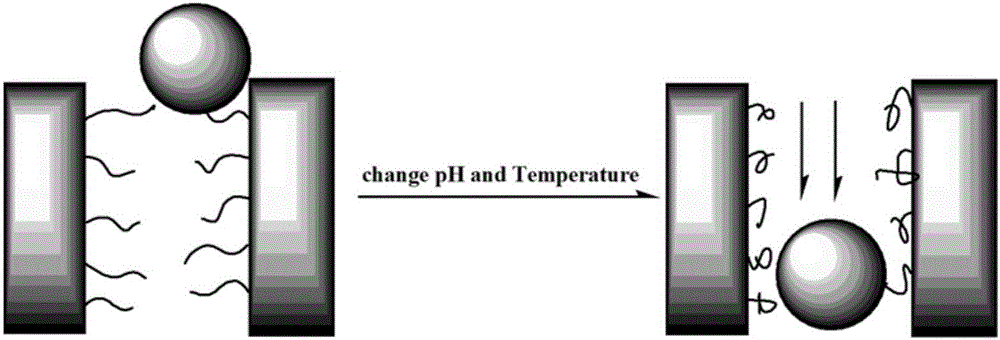

A polysulfone porous membrane responsive to temperature and acidity and its preparation method and application

An acidity-responsive, porous membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high cost, high operating conditions, adverse effects of basement membrane, etc., and achieve strict and reliable structure control, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

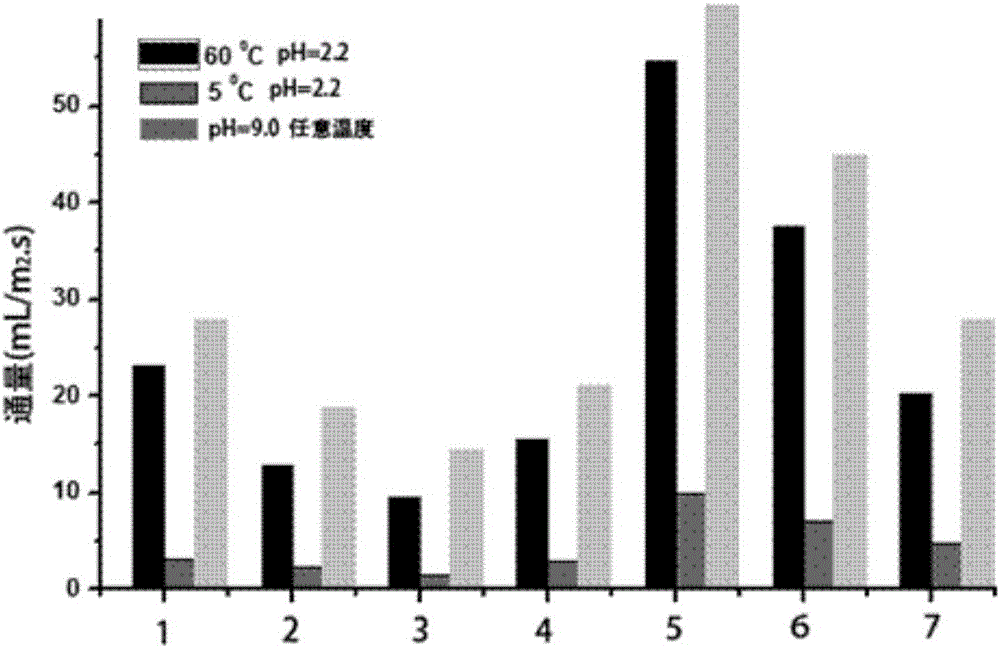

Examples

Embodiment 1

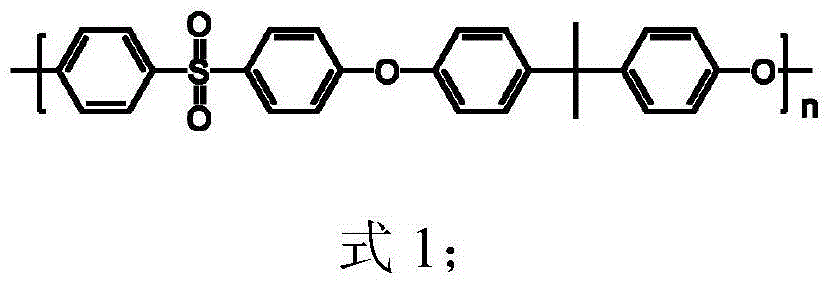

[0053] (1) Blending of polysulfone industrial products and polysulfone azide: Add 1 part of polysulfone S3010, 14 parts of polysulfone azide, and 1 part of polyethylene glycol (Mw=2000Da) to 40 parts of methylpyrrolidone , stirred at 25°C until transparent and clear to obtain the casting solution of polysulfone industrial products and polysulfone azide blend membrane;

[0054] (2) Preparation of porous membrane from polysulfone / polysulfone azide blend: Pour the casting liquid of the polysulfone industrial product and polysulfone azide blend membrane prepared in step (1) onto the substrate of the film applicator , adjust the height of the scraper to 150um, squeegee to form a film, and immerse the substrate in water at 25°C; after the film is separated from the substrate, take out the film and dry it to prepare a polysulfone / polysulfone azide porous membrane. 5 ~ 10um, porosity 63%;

[0055] (3) Modification of the surface of polysulfone / polysulfone azide porous membrane:

[0...

Embodiment 2

[0060] (1) Blending polysulfone industrial products with polysulfone azide: Add 3 parts of polysulfone S3010, 12 parts of polysulfone azide, and 1 part of polyethylene glycol (Mw=2000Da) to 40 parts of dimethyl ethylene glycol In amide, stir until transparent and clear at 25°C to obtain a casting solution for a blend film of polysulfone industrial products and polysulfone azide;

[0061] (2) Preparation of porous membrane from polysulfone / polysulfone azide blend: Pour the casting liquid of the polysulfone industrial product and polysulfone azide blend membrane prepared in step (1) onto the substrate of the film applicator , adjust the height of the scraper to 150um, squeegee to form a film, and immerse the substrate in ethanol at 25°C; after the film is separated from the substrate, take out the film and dry it to prepare a polysulfone / polysulfone azide porous membrane. 5 ~ 10um, porosity 63%;

[0062] (3) Modification of the surface of polysulfone / polysulfone azide porous me...

Embodiment 3

[0067] (1) Blending polysulfone industrial products with polysulfone azide: Add 5 parts of polysulfone S3010, 10 parts of polysulfone azide, and 1 part of polyethylene glycol (Mw=2000Da) to 40 parts of dimethylformaldehyde In amide, stir until transparent and clear at 25°C to obtain a casting solution for a blend film of polysulfone industrial products and polysulfone azide;

[0068] (2) Preparation of porous membrane from polysulfone / polysulfone azide blend: Pour the casting liquid of the polysulfone industrial product and polysulfone azide blend membrane prepared in step (1) onto the substrate of the film applicator , adjust the height of the scraper to 150um, scrape to form a film, and immerse the substrate in methanol at 25°C; after the film is separated from the substrate, take the film out and dry it to prepare a polysulfone / polysulfone azide porous membrane. 5 ~ 10um, porosity 63%;

[0069] (3) Modification of the surface of polysulfone / polysulfone azide porous membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com