Method for reducing graphene oxide

A graphene and solution technology, applied in the field of reducing graphene oxide, can solve problems such as irreversible agglomeration, and achieve the effect of simple preparation method, green reduction degree, and promotion of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Specifically include the following steps:

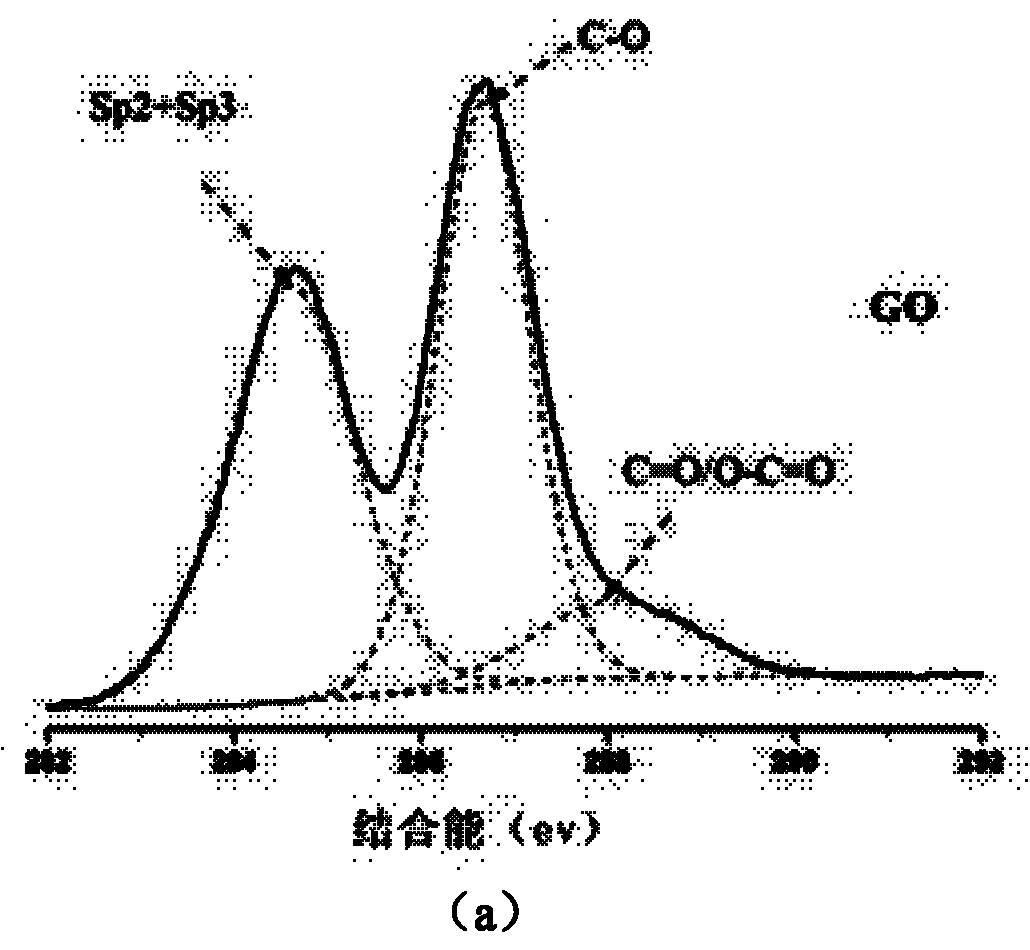

[0032] (1) Preparation of graphite oxide powder: Mix 3g of graphite, 18g of potassium permanganate, 360mL of concentrated sulfuric acid, and 40mL of phosphoric acid, stir magnetically in a water bath at 50°C for 12 hours, then pour 6mL of 30Wt% H2O2 and 200mL of ice cubes into a beaker , pour the reaction solution on ice cubes, centrifuge, pour off the supernatant, wash with 30% HCl, centrifuge for 1h, and wash twice with ethanol and deionized water in the same way. Freeze-dry to obtain graphite oxide powder.

[0033] (2) Prepare 1 L of 100 mg / L fulvic acid aqueous solution.

[0034] (3) Weigh 500 mg of graphite oxide and add it to the fulvic acid solution, ultrasonically disperse for 30 minutes to obtain a uniformly dispersed mixed solution, in which the concentration of fulvic acid is 100 mg / L, and the concentration of graphene oxide is 500 mg / L.

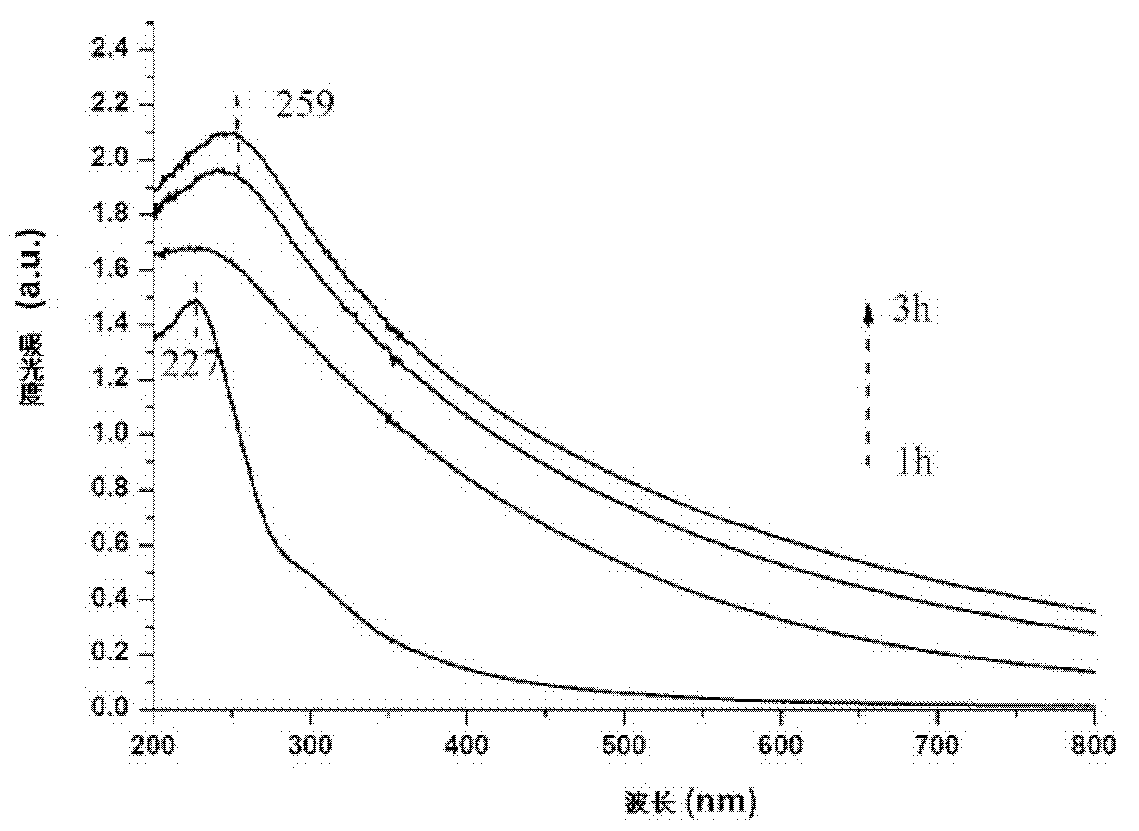

[0035] (4) Protect from light, and evenly expose nitrogen to the mixed solu...

Embodiment 2

[0041] Specifically include the following steps:

[0042] (1) The preparation process is the same as in Example 1 to obtain graphite oxide powder.

[0043] (2) Prepare 1 L of ethanol solution of 100 mg / L humic acid.

[0044] (3) Weigh 500 mg of graphite oxide and add it to the humic acid ethanol solution, and disperse it by ultrasonic for 30 minutes to obtain a uniformly dispersed mixed solution, in which the concentration of humic acid is 100 mg / L, and the concentration of graphene oxide is 500 mg / L.

[0045] (4) Protect from light, and evenly expose nitrogen to the mixed solution for 30 minutes.

[0046] (5) Turn on the simulated sunlight light source, irradiate, and control the temperature at room temperature until the color of the reaction solution remains basically unchanged.

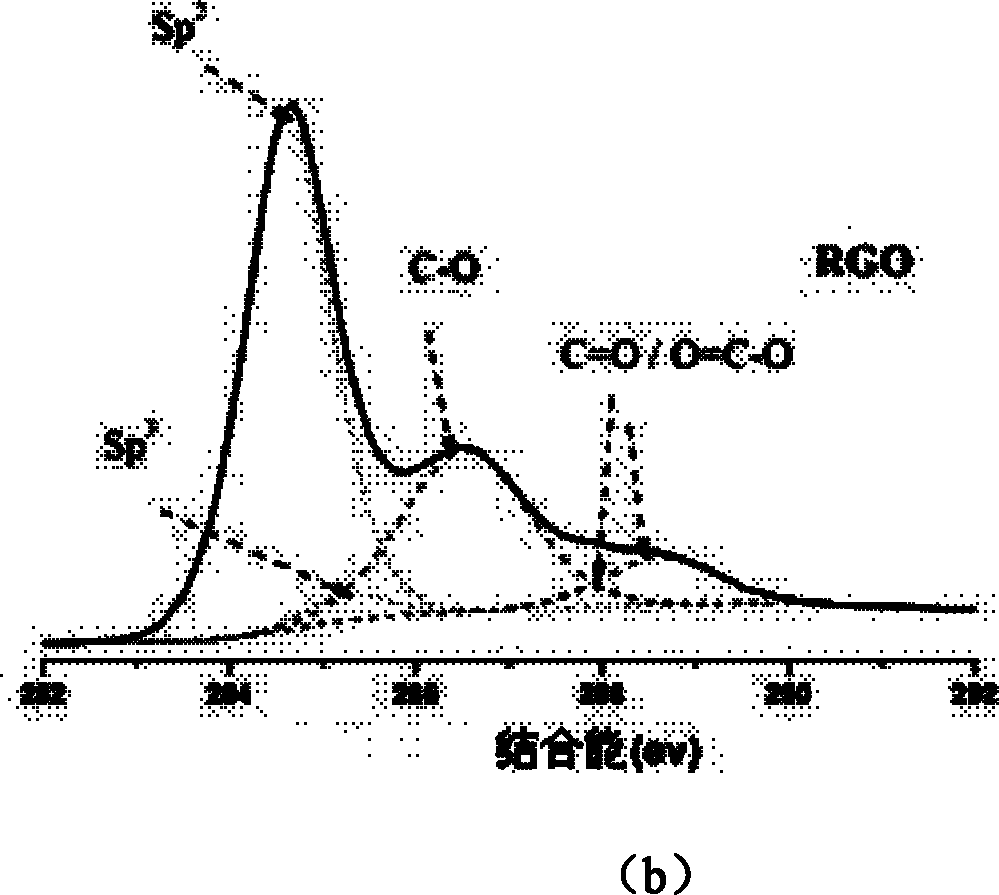

[0047] After the reaction, the originally yellow graphite oxide mixed solution turned into a black mixed solution, and the solution did not agglomerate after the reaction.

[0048] (6) Centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com