Method for machining round-section polytetrafluoroethylene filament by virtue of cutting-hot melting shaping method

A technology of polytetrafluoroethylene and circular cross-section, which is applied in the direction of filament/wire forming, artificial filament heat treatment, single-component halogenated hydrocarbon artificial filament, etc., and can solve the problem of reducing the overall mechanical index and damage of filter bag materials, etc. problems, to achieve significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

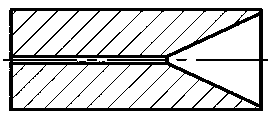

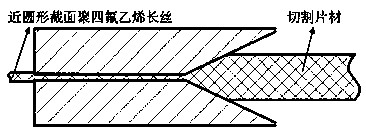

Image

Examples

Embodiment 1

[0028] (1) Mixing: Mix the 216 polytetrafluoroethylene dispersion resin powder and liquid paraffin of Zhonghao Chenguang Chemical Research Institute according to the weight ratio of polytetrafluoroethylene dispersion resin powder to liquid paraffin as 1:0.2, and mix them evenly at 20°C Stand at high temperature for 144 hours, and then stand at 80°C for 10 hours, so that the polytetrafluoroethylene dispersion resin powder and liquid paraffin are fully mixed to form polytetrafluoroethylene materials;

[0029] (2) Compacting and calendering: the polytetrafluoroethylene material is pressed into a cylindrical blank on a compacting machine at 20°C, and the blank is extruded into a rod at a temperature of 40°C through a pusher, and then Calendered at 40°C by a calender to form a polytetrafluoroethylene base tape;

[0030] (3) Longitudinal stretching: the polytetrafluoroethylene base tape is stretched longitudinally in an oven at 180°C to obtain a degreased base tape;

[0031] (4) Cu...

Embodiment 2

[0034] (1) Mixing: Mix the F106 polytetrafluoroethylene dispersion resin powder and petroleum ether of Daikin Company in Japan according to the weight ratio of polytetrafluoroethylene dispersion resin powder to petroleum ether as 1:0.28, and mix them evenly at a temperature of 40°C. Stand for 96 hours, then stand at 40°C for 16 hours to fully mix the polytetrafluoroethylene dispersion resin powder and petroleum ether to form polytetrafluoroethylene materials;

[0035] (2) Compacting and calendering: the polytetrafluoroethylene material is pressed into a cylindrical blank on a compacting machine at 30°C, and the blank is extruded into a rod at a temperature of 60°C through a pusher, and then Calendered at 60°C by a calender to form a polytetrafluoroethylene base tape;

[0036] (3) Longitudinal stretching: the polytetrafluoroethylene base tape is stretched longitudinally in an oven at 300°C to obtain a degreased base tape;

Embodiment 3

[0040] (1) Mixing: Mix the 216 polytetrafluoroethylene dispersion resin powder and kerosene of Zhonghao Chenguang Chemical Research Institute according to the weight ratio of polytetrafluoroethylene dispersion resin powder to kerosene as 1:0.22, and mix them evenly at a temperature of 30°C Stand still for 100 hours, then stand still at a temperature of 60°C for 12 hours, so that the polytetrafluoroethylene dispersion resin powder and kerosene are fully mixed to form polytetrafluoroethylene materials;

[0041] (2) Compacting and calendering: the polytetrafluoroethylene material is pressed into a cylindrical blank on a compacting machine at 25° C., and the blank is extruded into a rod at a temperature of 50° C. by a pusher, and then Calendered at 50°C by a calender to form a polytetrafluoroethylene base tape;

[0042] (3) Longitudinal stretching: the polytetrafluoroethylene base tape is stretched longitudinally in an oven at 200°C to obtain a degreased base tape;

[0043] (4) C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com