Preparation method of low-temperature germanium dioxide-organic modified silicate composite material with improved optical third-order nonlinear quality factor

A technology of third-order nonlinearity and quality factor, which is applied in nonlinear optics, optics, instruments, etc., can solve problems affecting the characteristics of thin-film waveguides, etc., achieve excellent third-order nonlinear quality factor, simple process requirements, and realize integration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) First mix 1 mole of γ-(2,3 glycidoxy)propyltrimethoxysilane, 3 moles of ethanol and 4 moles of deionized water, and then add 0.01 moles of 37% hydrochloric acid was continuously stirred as solution A;

[0020] 1 mole of germanium isopropoxide and 4 moles of 2-methoxyethanol were mixed and stirred continuously as solution B;

[0021] 2) Then, mix solution A and solution B at a molar ratio of 4:1 and stir to obtain a low-temperature organic-inorganic composite matrix mother liquor uniformly containing silicon germanium;

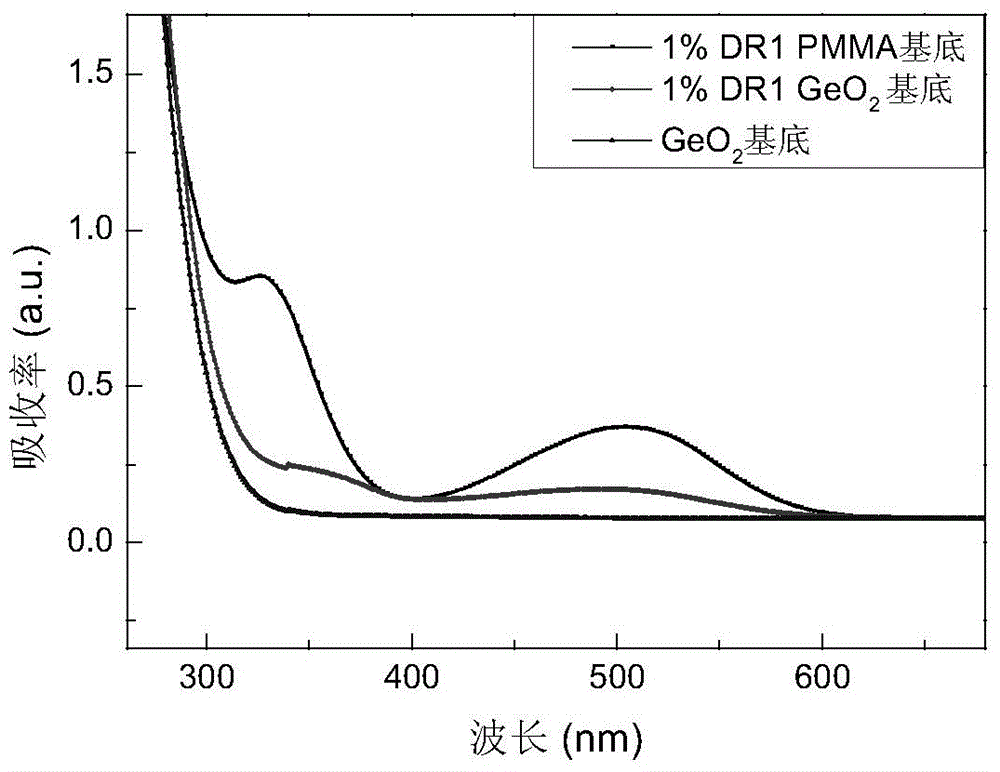

[0022] 3) Add 0.5% by weight of small disperse red molecules to the low-temperature organic-inorganic composite matrix mother liquor, and stir evenly at room temperature to obtain a spare suspension;

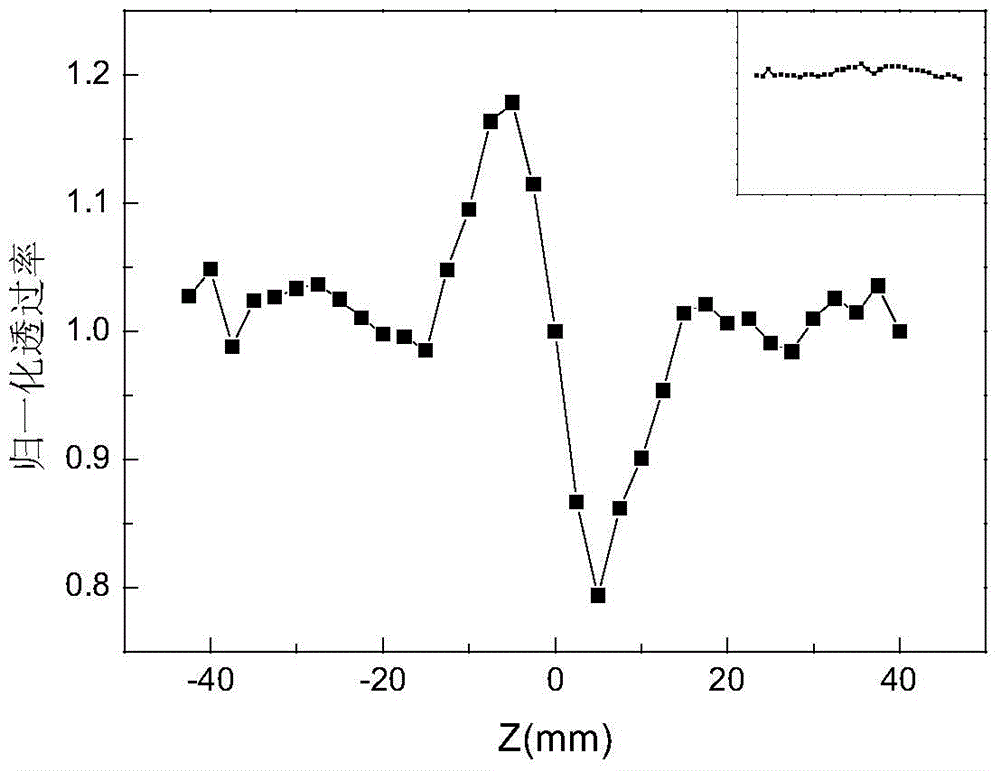

[0023] 4) Deposit the above-obtained suspension on a glass slide at a rotational speed of 3,000 revolutions per minute by using a spin coating process, and then treat the deposited film sample at 45°C for 20 minutes to obtain a single layer with A low...

Embodiment 2

[0025] 1) First mix 1 mole of γ-(2,3 glycidoxy)propyltrimethoxysilane, 5 moles of ethanol and 3 moles of deionized water, and then add 0.01 moles of 37% hydrochloric acid was continuously stirred as solution A;

[0026] 1 mole of germanium isopropoxide and 5 moles of 2-methoxyethanol were mixed and stirred continuously as solution B;

[0027] 2) Then, mix solution A and solution B at a molar ratio of 4:1 and stir to obtain a low-temperature organic-inorganic composite matrix mother liquor uniformly containing silicon germanium;

[0028] 3) Add 1% by weight of small disperse red molecules to the low-temperature organic-inorganic composite matrix mother liquor, and stir evenly at room temperature to obtain a spare suspension;

[0029] 4) Deposit the above-obtained suspension on a glass slide at a rotational speed of 3,300 revolutions per minute by using a spin coating process, and then treat the deposited film sample at 48°C for 17 minutes to obtain a monolayer Moreover, the s...

Embodiment 3

[0031] 1) First mix 1 mole of γ-(2,3 glycidoxy)propyltrimethoxysilane, 6 moles of ethanol and 6 moles of deionized water, and then add 0.01 moles of 37% hydrochloric acid was continuously stirred as solution A;

[0032] 1 mole of germanium isopropoxide and 6 moles of 2-methoxyethanol were mixed and stirred continuously as solution B;

[0033] 2) Then, mix solution A and solution B at a molar ratio of 4:1 and stir to obtain a low-temperature organic-inorganic composite matrix mother liquor uniformly containing silicon germanium;

[0034] 3) Add 1.5% of its weight of small disperse red molecules into the low-temperature organic-inorganic composite matrix mother liquor, and stir evenly at room temperature to obtain a spare suspension;

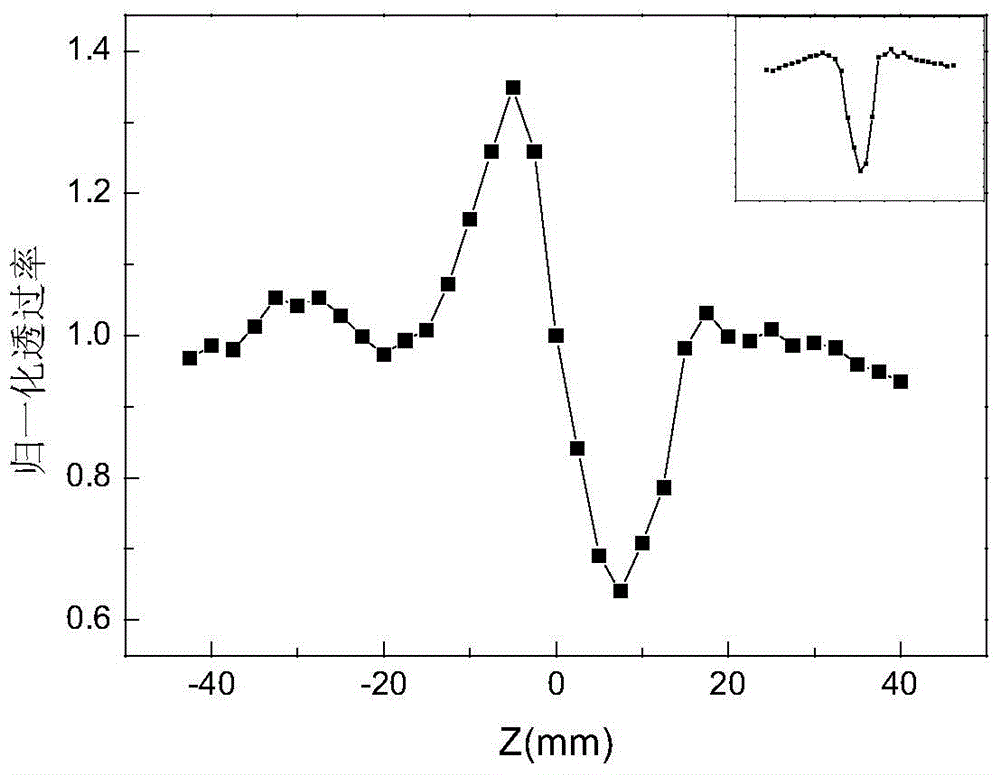

[0035] 4) Deposit the above-obtained suspension on a glass slide at a rotational speed of 3,700 rpm by using a spin coating process, and then treat the deposited film sample at 52°C for 13 minutes to obtain a monolayer Moreover, the surface is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com