Preparation method of all aluminum doped N-type solar cell

A solar cell, aluminum doping technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as inability to weld battery components, inability to fully form PN junctions, and large sintering depths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

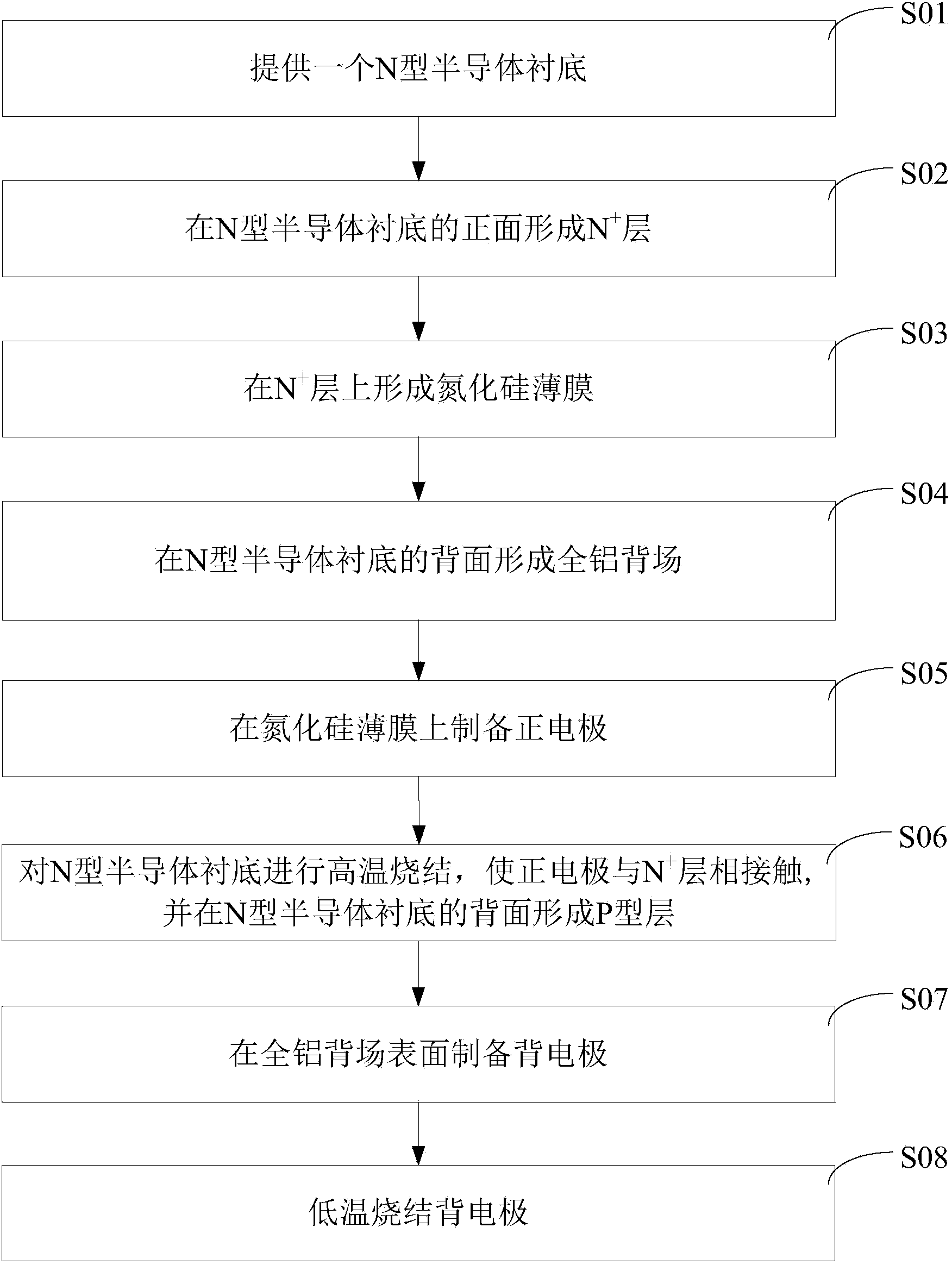

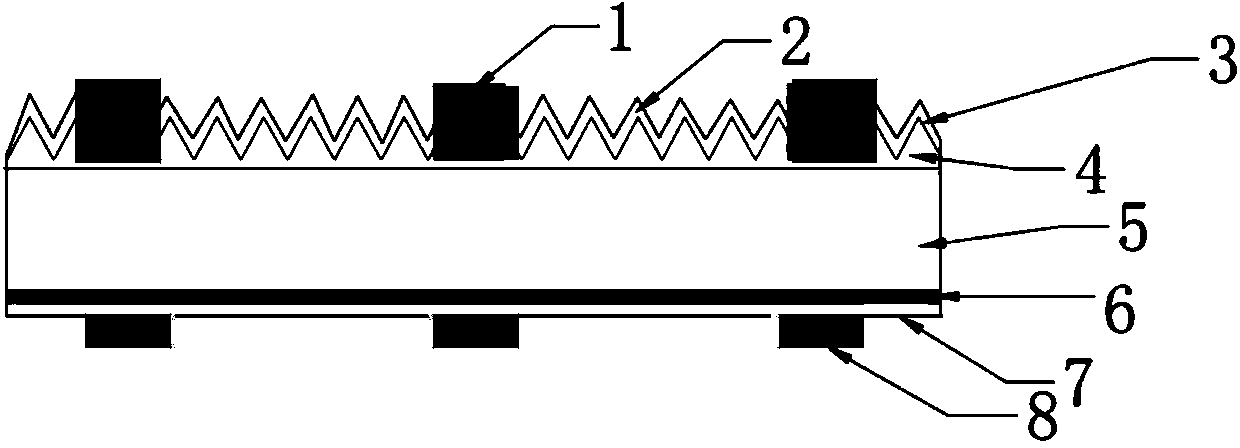

[0058] The following will be combined with Figure 2-4 The method for preparing the above-mentioned all-aluminum-doped N-type solar cell of the present invention is described in detail.

[0059] see figure 2 , figure 2 It is a schematic flow chart of a method for preparing an all-aluminum-doped N-type solar cell according to a preferred embodiment of the present invention. The preparation method of all-aluminum-doped N-type solar cell in this preferred embodiment of the present invention, comprises the following steps:

[0060] Step S01: providing an N-type semiconductor substrate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com