Tetrahydropalmatine intra-gastric floating oral microsphere

A technology of tetrahydropalmatine and gastric floating, applied in the field of gastric floating microspheres, which can solve the problems of large dose of dripping pills, inconvenient administration, low bioavailability, etc., achieve stable drug release speed, reduce the number of administrations, and improve the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

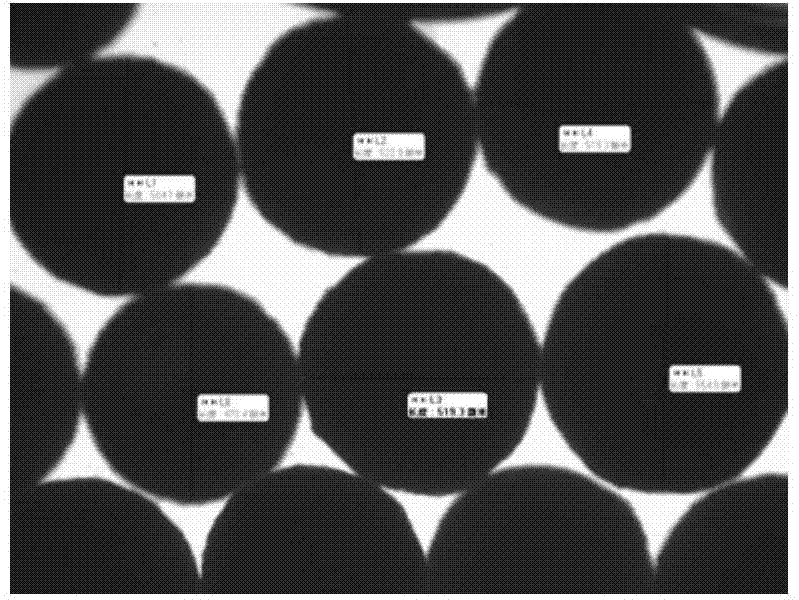

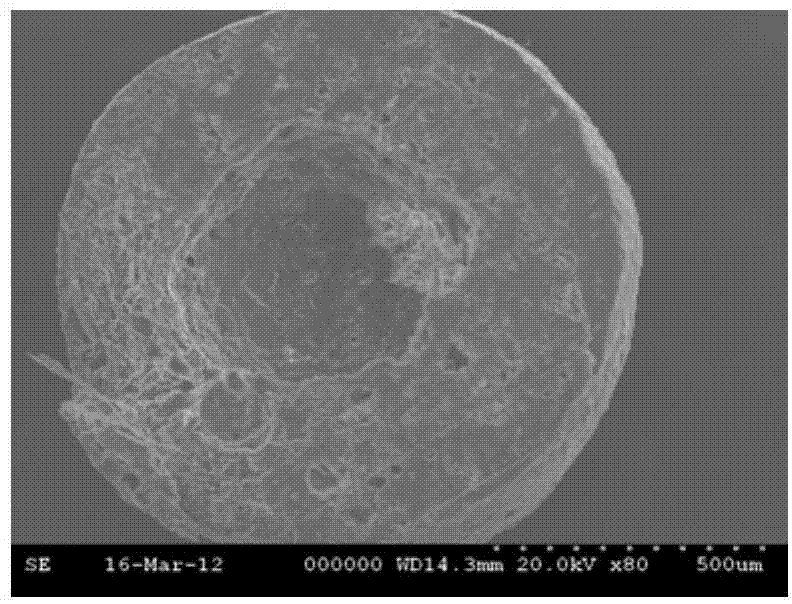

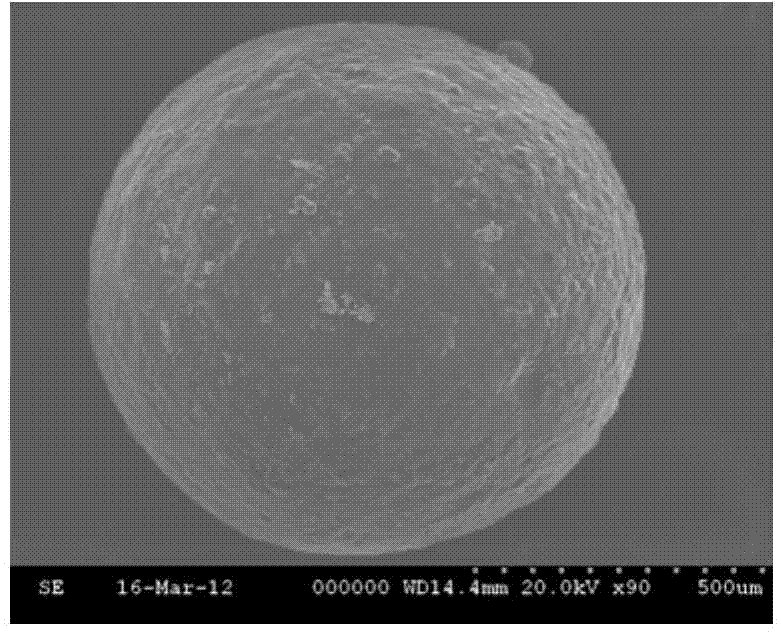

Embodiment 1

[0030] Weigh 0.6g THP and 0.8g ethyl cellulose (EC), mix well, dissolve in 20mL ethyl acetate to form an organic phase. In addition, 100 mL of PVA aqueous solution with a mass fraction of 0.5% was prepared as the water phase. Under the condition of a stirring speed of 50rpm, slowly add the organic phase to the water phase, and continue to stir at 35°C until the organic solvent is evaporated, let it stand for a certain period of time, filter, discard the filtrate, and wash the filter cake with distilled water (50mL× 3) Vacuum drying at 50°C for 8.5 hours to obtain 1.2 g of light yellow microspheres. The average particle size of the microspheres is 518.5 μm, the drug loading capacity is 40.3%, and the encapsulation efficiency is 92%. The microspheres have a round appearance, a hollow structure, and a bulk density of 0.44. meet the requirements.

Embodiment 2

[0032] Weigh 1g THP and 1.2g Eugragit S100 (a kind of acrylic resin) respectively, mix them evenly, and dissolve them in 120mL ethanol to form an organic phase. Another 150 mL of PVA aqueous solution with a mass fraction of 0.5% was prepared as the water phase. Under the condition of 200rpm stirring speed, slowly add the organic phase to the water phase, and continue to stir at 30°C until the organic solvent evaporates, let it stand for a certain period of time, filter, discard the filtrate, and wash the filter cake with distilled water (100mL×2) , and vacuum-dried at 35°C for 12 hours to obtain 1.7 g of pale yellow microspheres. The average particle size of the microspheres is 480.1 μm, the drug loading capacity is 35.2%, and the encapsulation efficiency is 89.3%. The microspheres have a round appearance, a hollow structure, and a bulk density of 0.48. meet the requirements.

Embodiment 3

[0034] Weigh 6g THP and 8g Eugragit L100 respectively, mix well, dissolve in 80mL dichloromethane to form an organic phase. Another 600 mL of PVA aqueous solution with a mass fraction of 0.5% was prepared as the water phase. Under the condition of 150rpm stirring speed, slowly drop the organic phase into the water phase, keep stirring at 38°C until the organic solvent evaporates, let it stand for a certain period of time, filter, discard the filtrate, and wash the filter cake with distilled water (150mL×4) , and vacuum-dried at 52°C for 7 hours to obtain 10.5 g of pale yellow microspheres. The average particle size of the microspheres was measured to be 523.9 μm, the drug loading capacity was 34.1%, and the encapsulation efficiency was 86.7%. The appearance of the microspheres was round, with a hollow structure, and the bulk density was 0.51. All meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com