Preparation method of basic copper sulfate/metal organic framework core-shell microsphere

A metal-organic framework, core-shell microsphere technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of harsh reaction conditions, limited batch production and application, cumbersome process, etc., and achieve mild reaction conditions and short cycle times. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0024] 1) Prepare 4 mL of copper sulfate solution with a concentration of 0.75 mol / L at room temperature, add 0.024 mol / L 1,3-propylenediamine solution, then let stand at room temperature for 2 h, filter and wash, and dry at 60 °C After 12 h, basic copper sulfate microspheres with core-shell structure were obtained;

[0025] 2) Disperse 0.003 mol of core-shell structure basic copper sulfate microspheres in a mixed solution of 4 mL of ethanol and water (the molar ratio of ethanol and water is 1:1), and then add 3 mL of 0.05 mol / L ethanol solution of terephthalic acid, react at room temperature for 1 h, filter and wash, and dry at 60 °C for 12 h to obtain basic copper sulfate / MOF core-shell microspheres, whose MOF shell is Cu -BDC.

Embodiment example 2

[0027] 1) Prepare 4 mL of copper sulfate solution with a concentration of 0.75 mol / L at room temperature, add 0.024 mol / L of 1,3-propylenediamine solution, then stand at room temperature for 2 h, filter and wash, and dry at 60 °C After 12 h, basic copper sulfate microspheres with core-shell structure were obtained;

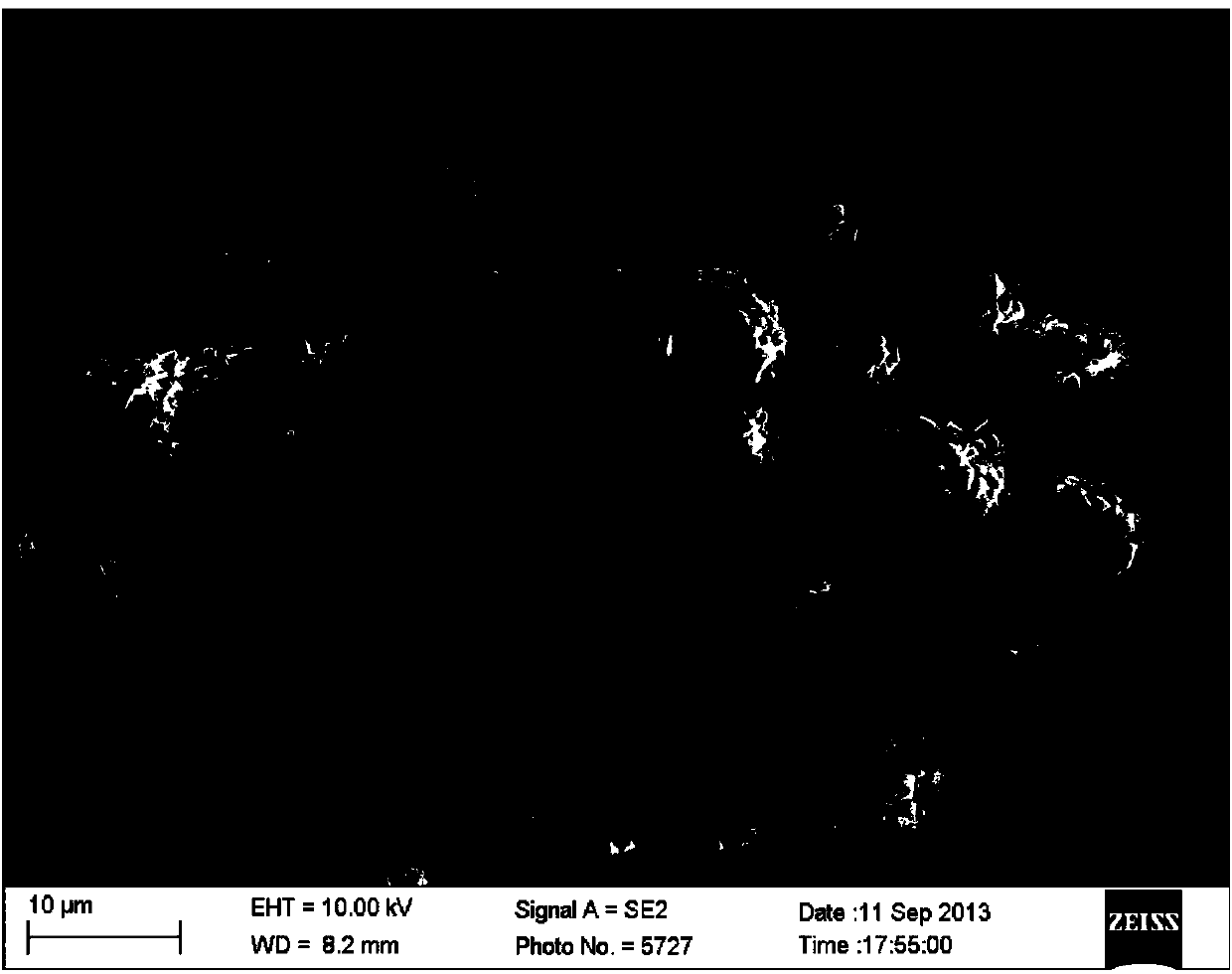

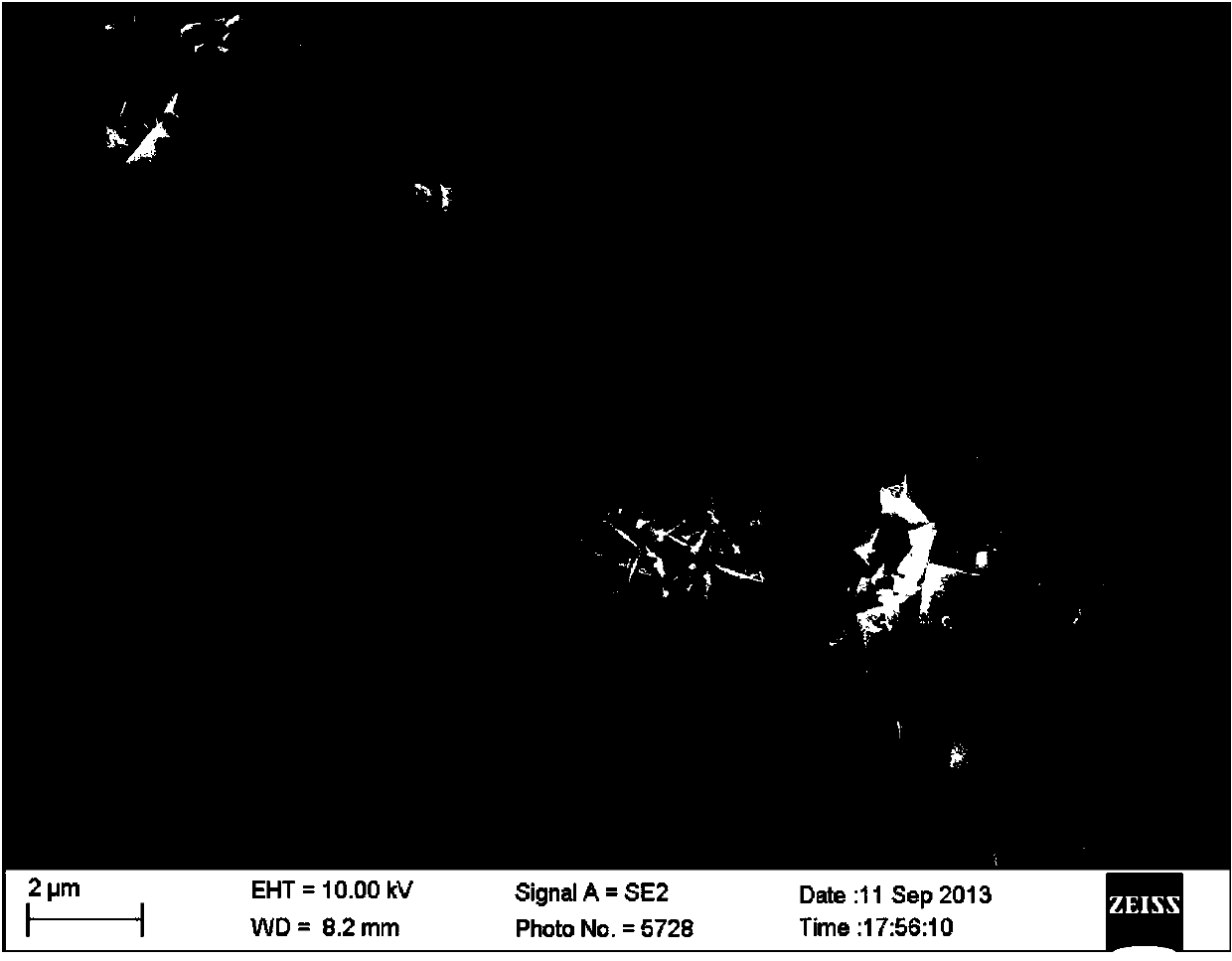

[0028] 2) Disperse 0.003 mol of core-shell structure basic copper sulfate microspheres in a mixed solution of 4 mL of ethanol and water (the molar ratio of ethanol and water is 1:1), and then add 3 mL of 0.05 The ethanol solution of mol / L trimesic acid was reacted at room temperature for 1 h, filtered and washed, and dried at 60 °C for 12 h to obtain basic copper sulfate / MOF core-shell microspheres, and the MOF shell was Cu-BTC. The scanning electron microscope photograph of the product is as figure 1 , as shown in 2.

Embodiment example 3

[0030] 1) Prepare 4 mL of copper sulfate solution with a concentration of 0.75 mol / L at room temperature, add 0.024 mol / L 1,3-propylenediamine solution, then stand at room temperature for 2 h, filter and wash, and dry at 60 °C for 12 Obtain the basic copper sulfate microsphere of core-shell structure after h;

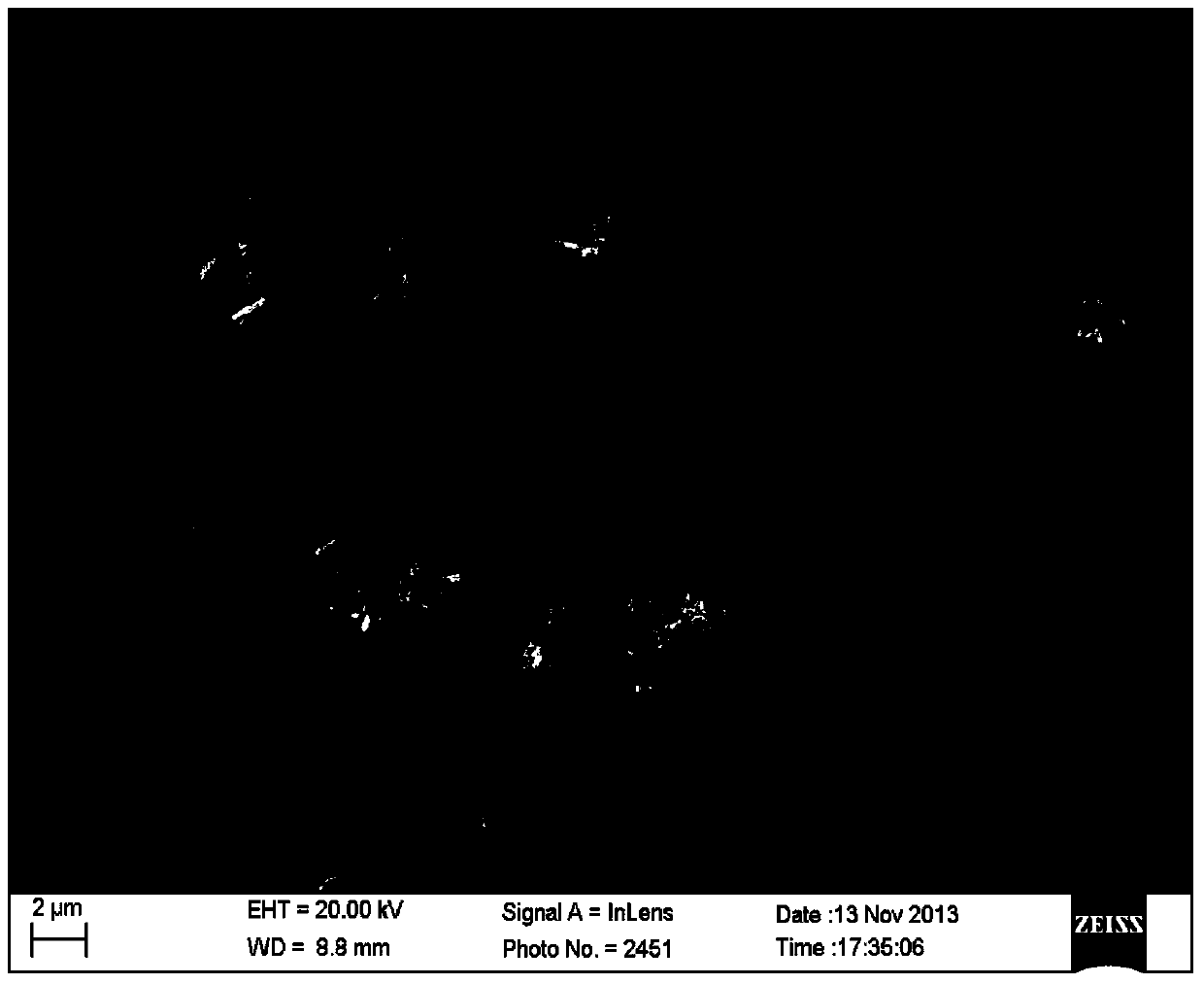

[0031] 2) Disperse 0.003 mol of core-shell structure basic copper sulfate microspheres in a mixed solution of 4 mL of ethanol and water (the molar ratio of ethanol and water is 1:1), and then add 3 mL of 0.05 mol / L ethanol solution of pyromellitic acid, react at room temperature for 1 h, filter and wash, and dry at 60 °C for 12 h to obtain basic copper sulfate / MOF core-shell microspheres, whose MOF shell is Cu -BTEC. The scanning electron microscope photograph of the product is as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com