A catalytic rectification packing with radial distribution capability

A catalytic rectification and radial distribution technology, applied in the field of structured packing, can solve the problems of large mass transfer and diffusion process resistance, increase mass transfer resistance, and reduce radial distribution capacity of packing, so as to improve reaction and separation efficiency, improve The ability of radial distribution, the effect of improving the effect of radial distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

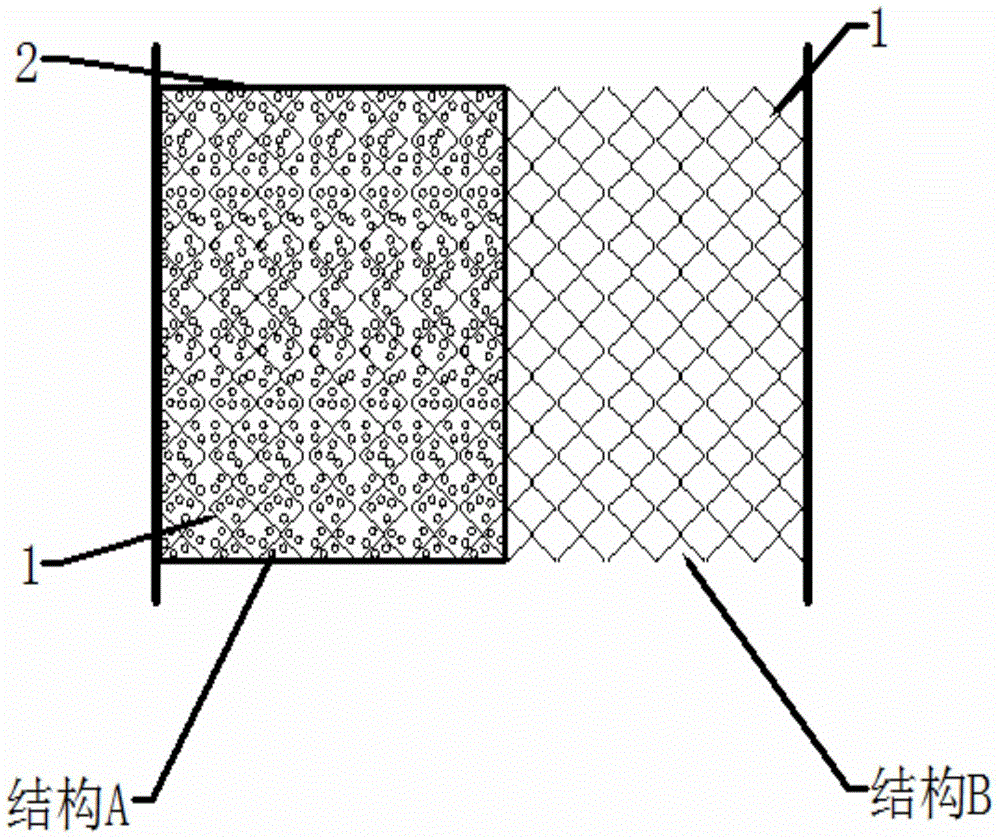

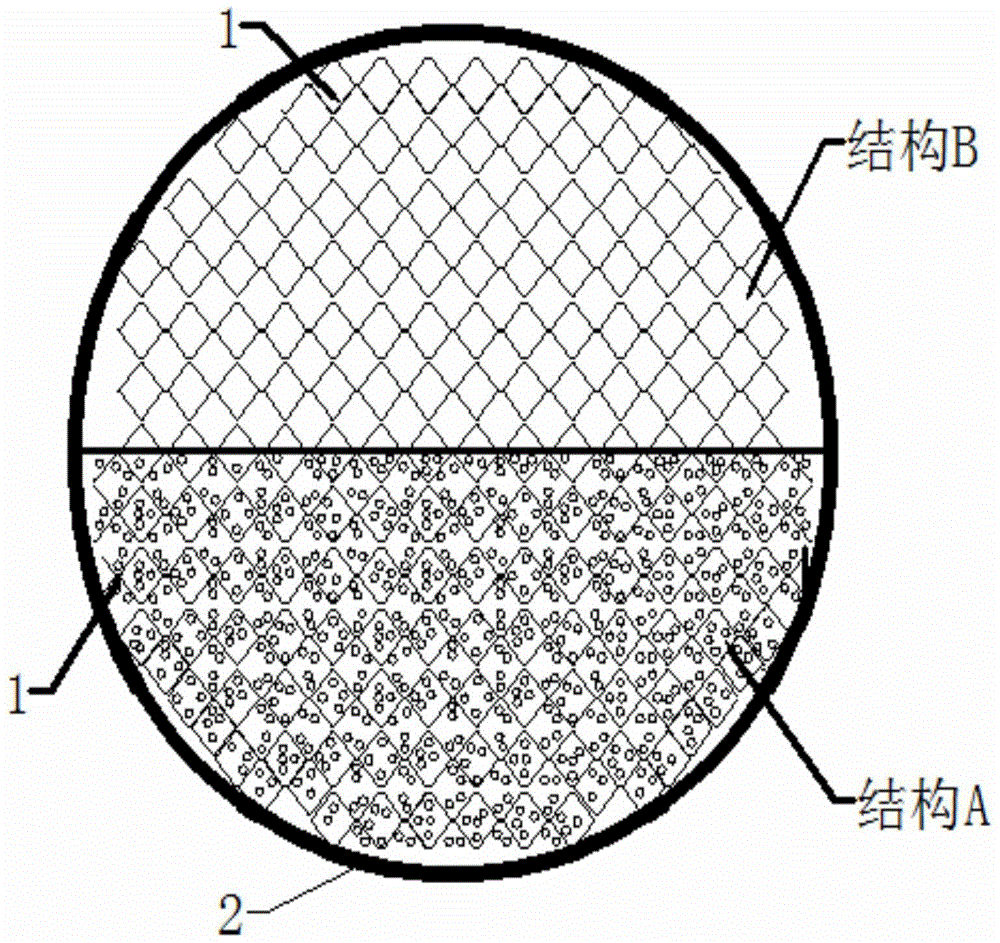

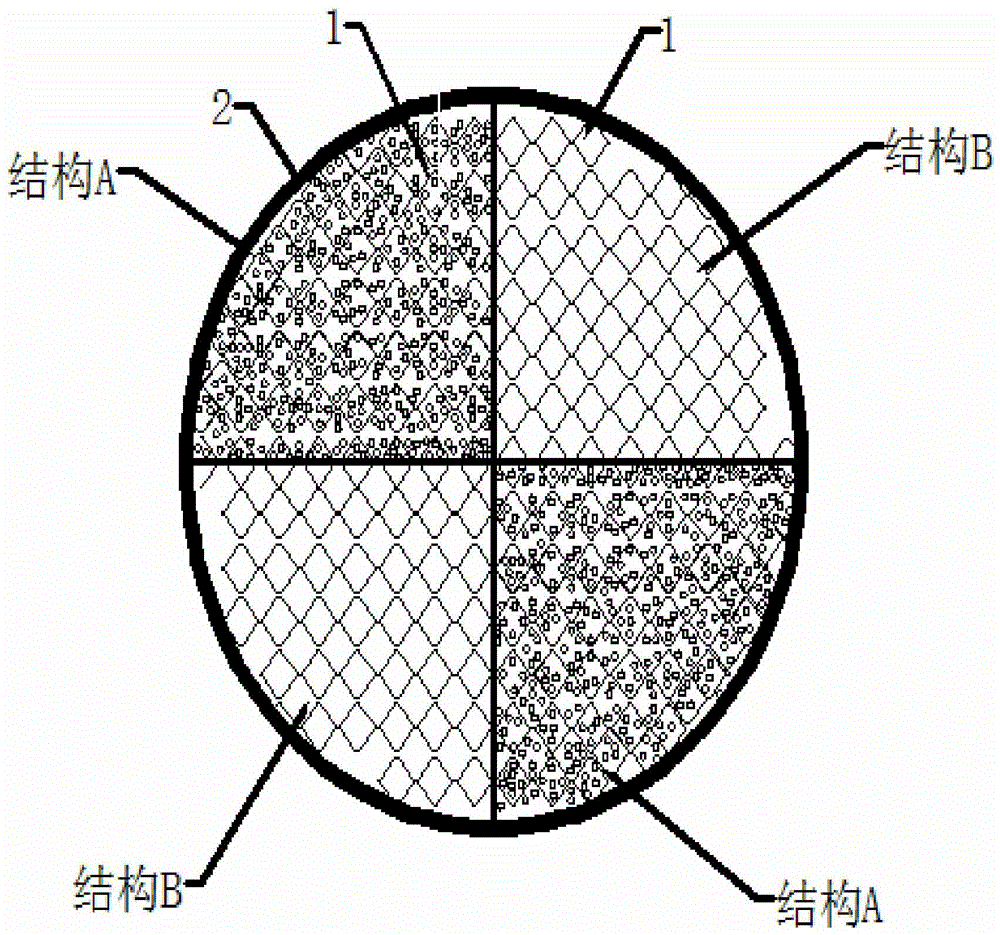

Embodiment 1

[0027] In the C4 catalytic rectification pretreatment unit, the C4 fraction from the MTBE unit has a relatively high content of dienes and dimethyl ether, etc., which cannot be directly used as raw materials for the alkylation reaction and require pretreatment. Using catalytic rectification technology, hydrofining and dimethyl ether removal are simultaneously completed in the catalytic rectification tower. The packing adopts window diversion packing and metal rolling orifice plate corrugated packing, and each layer adopts structured packing with n=1, among which structure A and structure B are respectively composed of 24 packing sheets, a total of 48 packing sheets. The catalyst is packed in packing sheets in structure A. The diameter of the tower is DN900, the height of the plate is 120mm, and the upper and lower plates are rotated 180° for installation. Comparing the catalytic rectification filler of the present invention with the use of ordinary bundled catalysts, experime...

Embodiment 2

[0029] In the liquid-solid three-phase catalytic rectification equipment of benzene chloride gas, chlorine gas reacts with benzene to produce chlorinated benzene. The packing adopts window-opening diversion packing and metal rolling orifice corrugated packing, and each layer adopts n=2 structured packing, in which structure A and structure B are respectively composed of 15 packing sheets, a total of 60 packing sheets. The catalyst is packed in packing sheets in structure A. The diameter of the tower is DN1000, the height of the plate is 140mm, and the upper and lower plates are rotated 90° for installation. Comparing the catalytic rectification filler of the present invention with the use of ordinary packaged catalysts, the experiment shows that the total pressure drop in the tower is reduced by 35%, and the chlorobenzene content in the final tower kettle is increased to 98%.

Embodiment 3

[0031] In the ethylene glycol monobutyl ether catalytic distillation equipment, ethylene glycol monobutyl ether is synthesized from ethylene oxide and n-butanol. The packing adopts window diversion packing and metal calendered orifice corrugated packing, and each layer adopts structured packing with n=4, among which structure A and structure B are respectively composed of 10 packing sheets, a total of 80 packing sheets. The catalyst is packed in packing sheets in structure A. The diameter of the tower is DN1200, the height of the plate is 170mm, and the upper and lower plates are rotated by 45° for installation. Comparing the catalytic rectification filler of the present invention with the use of common bundled catalysts, experiments show that the total pressure drop in the tower is reduced by 25%, and the final yield of ethylene glycol monobutyl ether is increased by 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com