Nanoporous alkali metal/alkaline earth metal titanate photocatalyst and preparation method thereof

A technology of alkaline earth metals and photocatalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low material efficiency, high energy consumption, high production costs, etc. problems, to achieve the effect of strong controllability, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

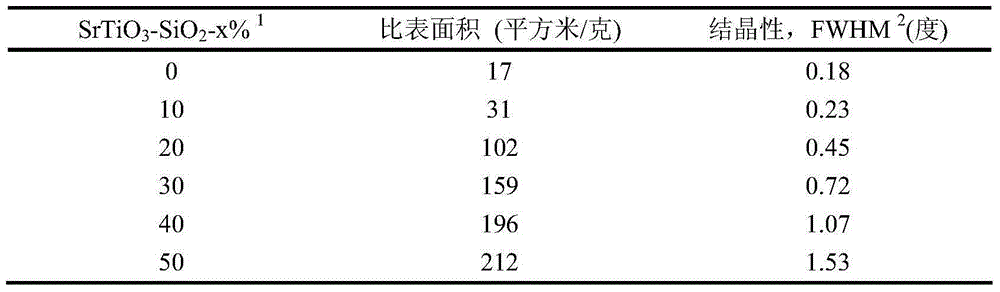

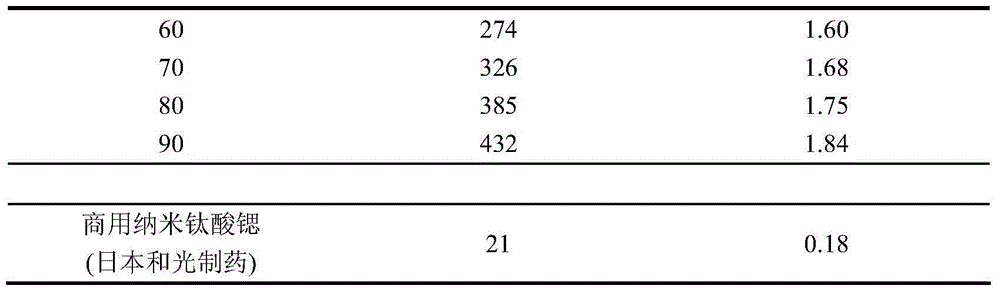

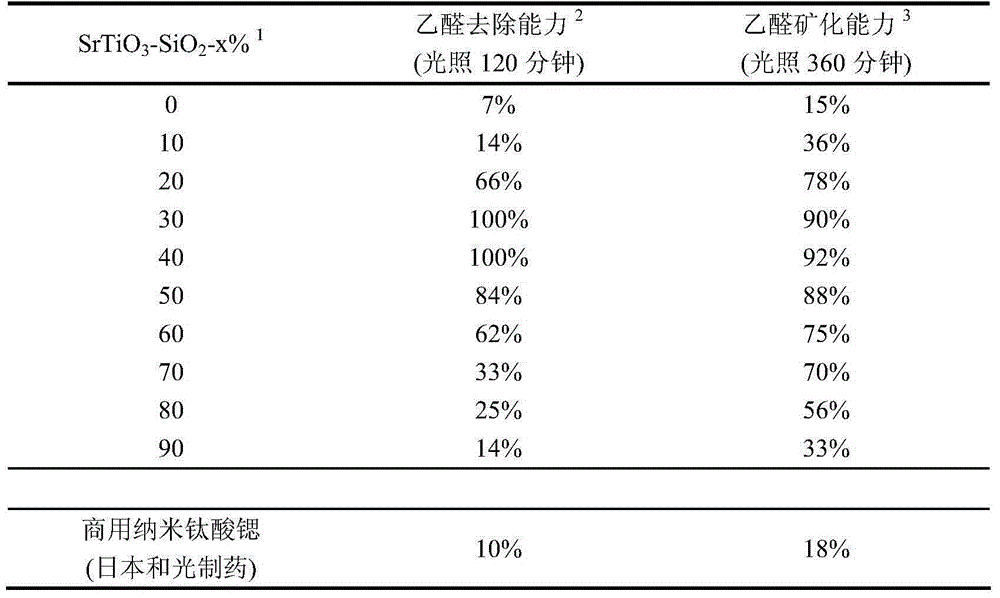

[0025] Nanotemplate-assisted preparation of nanoporous strontium titanate (SrTiO) with continuously tuned specific surface area and crystallinity3 ):

[0026] Weigh tetra-n-butoxytitanium (titaniumtetra-n-butoxide) and strontium acetate hemihydrate (strontium acetate hemihydrate) according to the stoichiometric ratio and dissolve them in absolute ethanol and glacial acetic acid respectively to prepare a clear solution, and then slowly mix the two solutions. By SrTiO 3 0, 10%, 20%, 30%, 40%, 50%, 60%, 70%, 80%, 90% mass ratio of theoretical weight by adding SiO 2 Nano-template (template size is 10-20 nanometers), sonicate for 30 minutes to disperse the nano-template evenly. Then place the suspension on a heating and stirring table for heating and stirring (temperature: 70 degrees Celsius; stirring speed: 60 rpm), and dry gel can be obtained after 8 hours. Grind the dry gel evenly, then disperse it in distilled water, sonicate for 1 minute, and then add NaOH to make the soluti...

Embodiment 2

[0038] Size Tuning of Nanoporous SrTiO Using Nanotemplates 3 The hole size:

[0039] Weigh tetra-n-butoxytitanium (titaniumtetra-n-butoxide) and strontium acetate hemihydrate (strontium acetate hemihydrate) according to the stoichiometric ratio and dissolve them in absolute ethanol and glacial acetic acid respectively to prepare a clear solution, and then slowly mix the two solutions. By SrTiO 3 Add three types of Al to 30% mass ratio of theoretical output weight 2 o 3 Nano-templates (template sizes are 3-8 nm, 10-20 nm and 50-70 nm), ultrasonic for 30 minutes to disperse the nano-templates evenly. Then place the suspension on a heating and stirring table for heating and stirring (temperature: 70 degrees Celsius; stirring speed: 60 rpm), and dry gel can be obtained after 8 hours. Grind the dry gel evenly, then disperse it in distilled water, sonicate for 1 minute, and then add KOH to make the solution alkalinity reach 2 mol / L. Transfer the suspension to the polytetrafluor...

Embodiment 3

[0041] Preparation of nanoporous doped strontium titanate:

[0042] To prepare chromium-doped strontium titanate Sr 0.95 Cr 0.05 TiO 3 Co-doped strontium titanate Sr with lanthanum and chromium 0.95 La 0.05 Ti 0.95 Cr 0.05 o 3 as an example. Weigh tetra-n-butoxytitanium (titaniumtetra-n-butoxide) and hydrated strontium acetate hemihydrate (strontiumacetatehemihydrate) according to the stoichiometric ratio and dissolve them in absolute ethanol and glacial acetic acid respectively to prepare a clear solution, then slowly mix the two solutions, and then Prepared Cr(NO 3 ) 3 and La(NO 3 ) 3 The ethylene glycol solution is added according to the doping amount and stirred evenly. Press Sr 0.95 Cr 0.05 TiO 3 and Sr 0.95 La 0.05 Ti 0.95 Cr 0.05 o 3 Add SiO to 40% mass ratio of theoretical output weight 2 Nano-template (template size is 10-20 nm), sonicate for 30 minutes to disperse the nano-template evenly. Then place the suspension on a heating and stirring tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com