Mesoporous co/ceo2 catalyst for hydrogen production by steam reforming of ethanol and preparation method thereof

A steam reforming and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the structure and crystal plane of carrier cerium oxide that cannot reach mesopores Different structural proportions, small specific surface area of the compound, etc., to achieve excellent anti-carbon deposition ability, good oxygen storage and release ability, and good product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Mesoporous CeO of the present invention 2 The carrier is prepared by the following method, and the steps include:

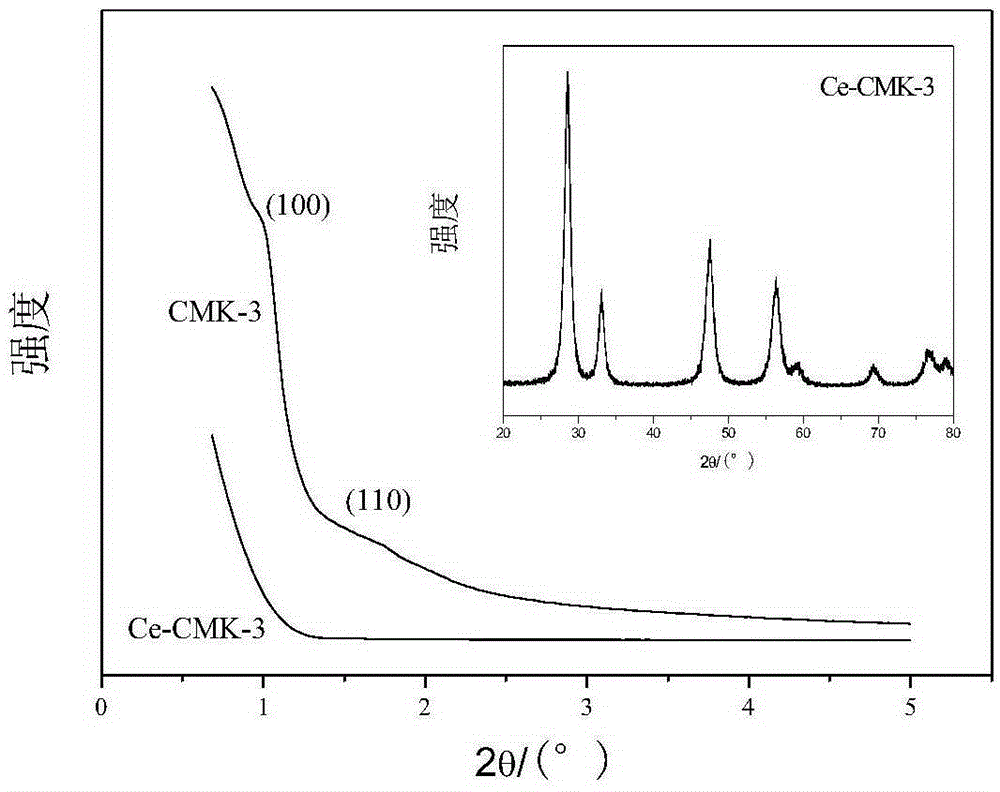

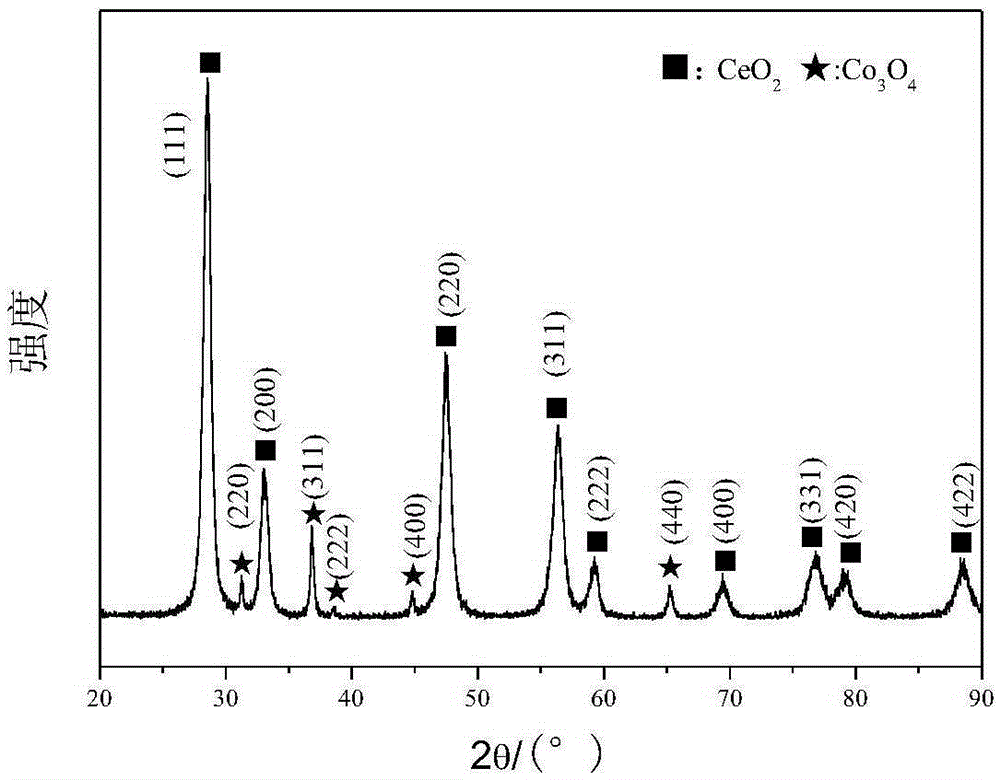

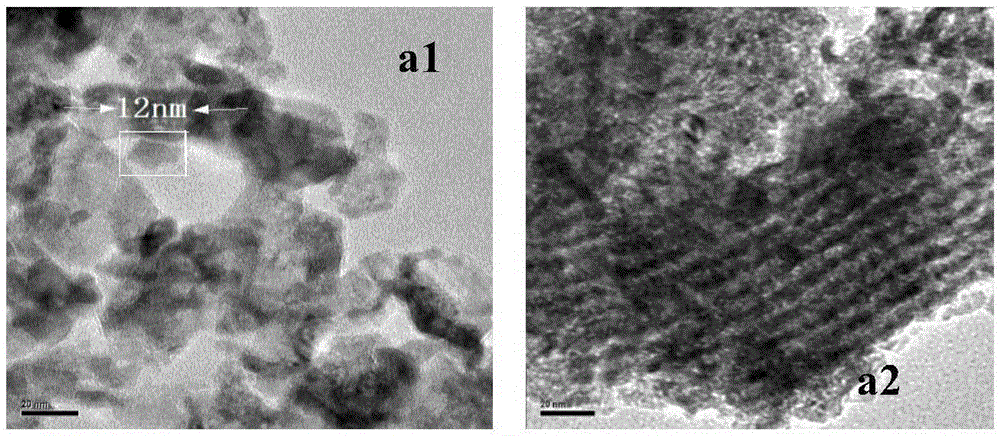

[0018] (1) Preparation of mesoporous carbon CMK-3. Dissolve 1.25g of sucrose completely in 5ml of deionized water, add 0.14g of concentrated sulfuric acid after the sucrose is dissolved, and mix well. Add 1g of SBA-15 to the sucrose solution and stir vigorously to completely impregnate the SBA-15 in the sucrose. The mass ratio of the sucrose, concentrated sulfuric acid, and template SBA-15 is 9:1:7. Afterwards, the mixture was dried in an oven at 100 °C for more than 6 h. In order to pre-polymerize sucrose in the pores of SBA-15, the composite was dried at 160°C for more than 6 hours, and the composite was filled for the second time. The second filling of the composite is to make the pores of the template agent be filled with the sucrose solution as comprehensively as possible. The content of the initial impregnation is sufficient, and only a small amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com