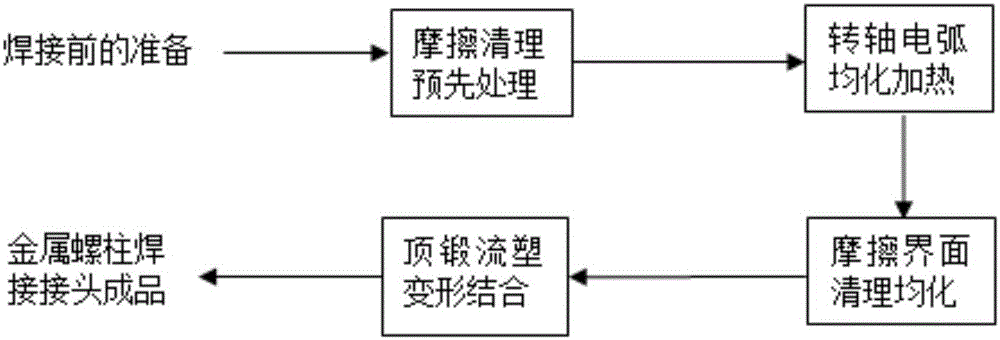

Arc metal stud welding method and device under friction cleaning and homogenization

A welding method and stud technology, applied in arc welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of reducing the welding performance of the workpiece, large heat-affected zone, necking, etc., and achieve improved welding quality and large diameter span , Improve the effect of temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

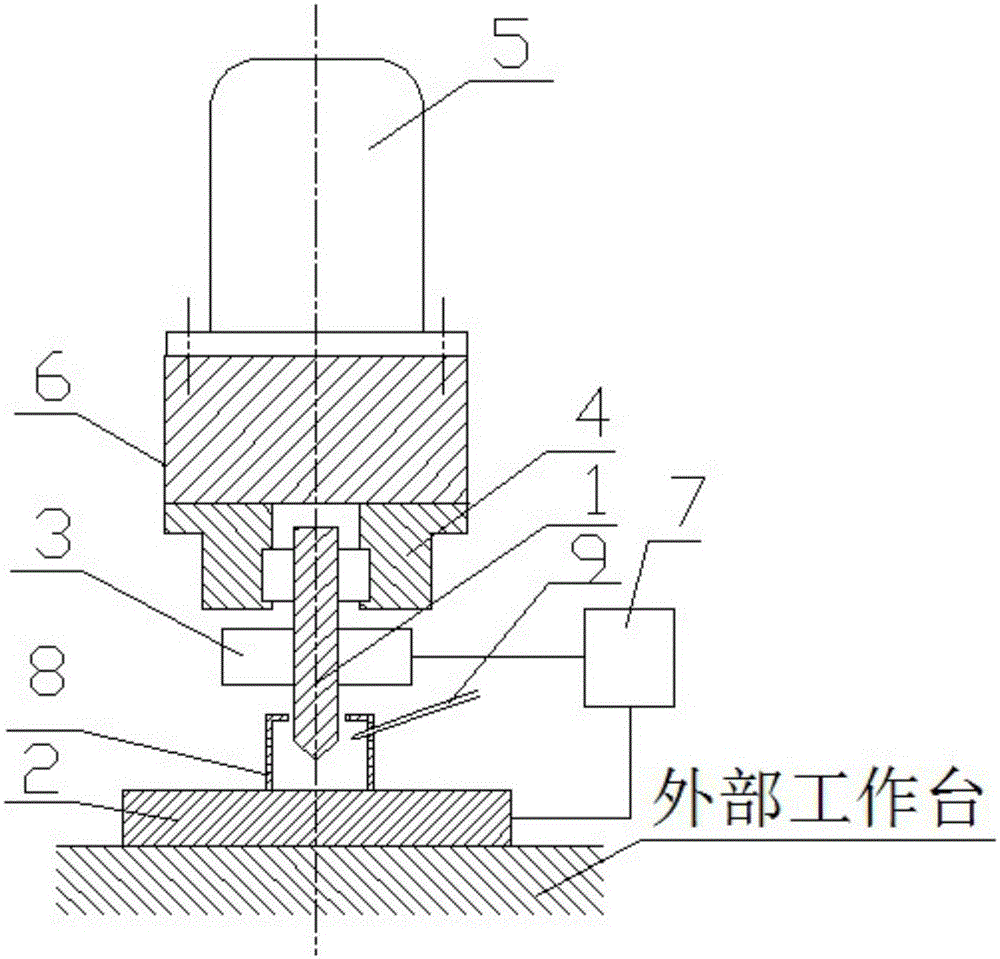

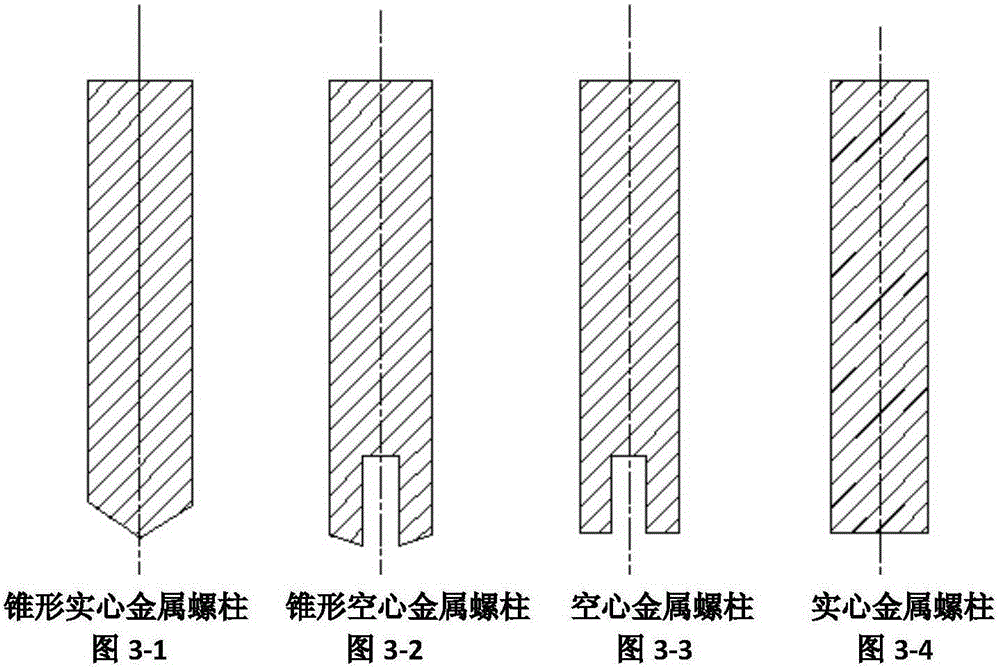

[0031] Example 1, taking the welded 30CrNi3MoV solid metal stud with a diameter of 6mm and a length of 80mm and the finished welded joint of 30CrNi3MoV with a plate thickness of 3mm as an example, the shielding gas is CO 2 , air flow 17L / min:

[0032] Step 1, friction cleaning pre-treatment: start the metal stud axial displacement device (6) and the motor (5), and the metal stud (1) rotates at 3000r / min, so that the metal stud (1) is on the metal stud shaft Under the joint action of the displacement device (6) and the motor (5), it moves along the axial direction and contacts the surface of the metal substrate (2), and at the same time applies a pressure of 5MPa, so that the end surface of the metal stud (1) is in contact with the surface of the metal substrate (2). Direct friction occurs on the surface. After 1 second of friction, remove impurities such as oxides and oil stains on the surface of the metal stud (1) and the metal substrate (2), and at the same time make the end...

Embodiment 2

[0036] Example 2, taking a 30CrNi3MoV conical metal stud with a diameter of 20mm and a length of 80mm as an example, and a finished welded joint of a 6061 aluminum alloy with a plate thickness of 40mm as an example, the shielding gas is Ar, and the gas flow rate is 16L / min:

[0037] Step 1, pre-treatment of friction cleaning: start the metal stud axial displacement device (6) and the motor (5), the speed of the metal stud (1) is 2000r / min, so that the metal stud (1) is on the metal stud shaft Under the joint action of the displacement device (6) and the motor (5), it moves along the axial direction and contacts the surface of the metal substrate (2), and at the same time applies a pressure of 18MPa, so that the end surface of the metal stud (1) is in contact with the surface of the metal substrate (2). Direct friction occurs on the surface. After 2 seconds of friction, remove impurities such as oxides and oil stains on the surface of the metal stud (1) and the metal substrate (...

Embodiment 3

[0041] Embodiment 3, taking the welded joint finished product of 6061 aluminum alloy hollow metal stud with a welding diameter of 30mm, inner hole diameter of 12mm, and a length of 80mm, and a 6061 aluminum alloy with a plate thickness of 80mm as an example, the shielding gas is Ar, and the gas flow rate is 18L / min:

[0042] Step 1, pre-treatment of friction cleaning: start the metal stud axial displacement device (6) and the motor (5), the speed of the metal stud (1) is 300r / min, so that the metal stud (1) is on the metal stud shaft Under the joint action of the displacement device (6) and the motor (5), it moves along the axial direction and contacts the surface of the metal substrate (2), and at the same time applies a pressure of 30MPa, so that the end surface of the metal stud (1) is in contact with the surface of the metal substrate (2). Direct friction occurs on the surface. After 3 seconds of friction, remove impurities such as oxides and oil stains on the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com