A kind of cu@sn core-shell structure high-temperature solder and its preparation method

A technology of core-shell structure and high-temperature solder, which is applied in the field of materials, can solve problems such as poor reliability, high cost, and substrate damage, and achieve the effects of simple and controllable process, improved impact resistance, and prevention of crack propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1C

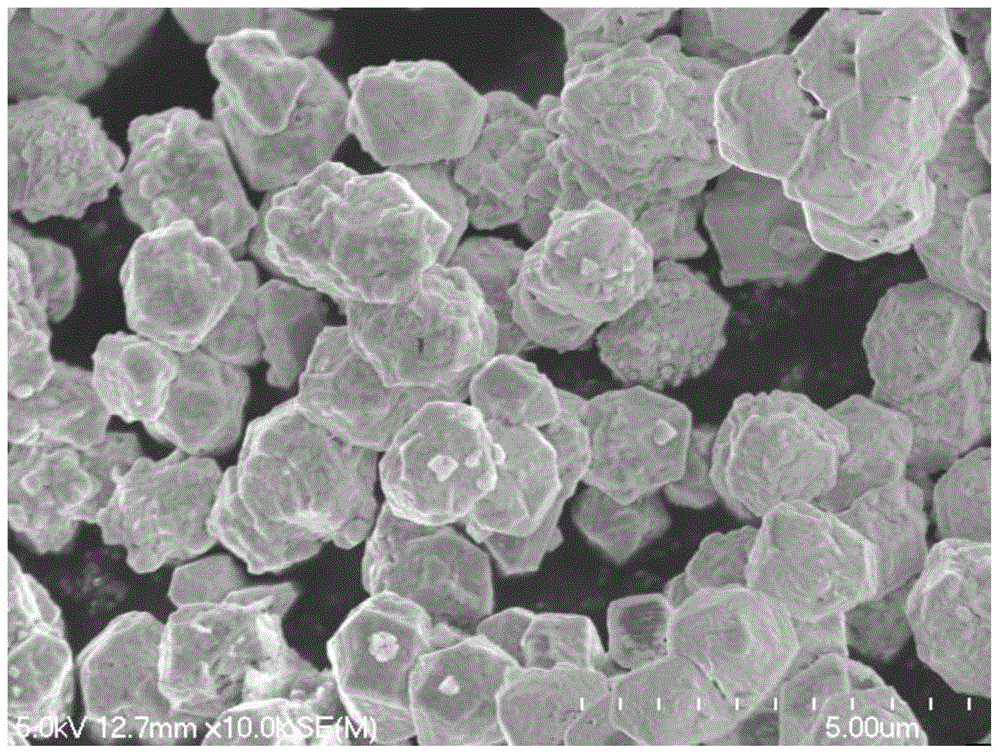

[0043] The preparation of the metal powder of embodiment 1Cu@Sn core-shell structure

[0044] In the first step, weigh 2g of Cu powder and 2g of PVP and mix them evenly and completely disperse them in 30ml of deionized water;

[0045] In the second step, 0.48g of Sn was weighed and dissolved in 60ml of deionized water, 4.57g of thiourea was weighed and added, and stirred evenly;

[0046] In the third step, the deionized water aqueous solution of the second step is added to the deionized water aqueous solution of the first step under constant stirring, and stirred at room temperature for 10 minutes to ensure complete reaction;

[0047] In the fourth step, the reaction product is repeatedly washed with deionized water or ethanol until the solution is clear and dried in the shade.

Embodiment 2

[0048] Preparation of metal powder of embodiment 2Cu@Sn core-shell structure

[0049] In the first step, weigh 2g of Cu powder and 2g of PVP and mix them evenly and completely disperse them in 30ml of deionized water;

[0050] In the second step, 0.96g of Sn was weighed and dissolved in 60ml of deionized water, 4.57g of thiourea was weighed and added, and stirred evenly;

[0051] In the third step, the deionized water aqueous solution of the second step is added to the deionized water aqueous solution of the first step under constant stirring, and stirred at room temperature for 20 minutes to ensure complete reaction;

[0052] In the fourth step, the reaction product is repeatedly washed with water or absolute ethanol until the solution is clear and dried in the shade.

Embodiment 3

[0053] Preparation of metal powder of embodiment 3Cu@Sn core-shell structure

[0054] In the first step, weigh 2g of Cu powder and 2g of PVP and mix them evenly and completely disperse them in 30ml of deionized water;

[0055] In the second step, 1.92g of Sn was weighed and dissolved in 60ml of deionized water, 9.14g of thiourea was weighed and added, and stirred evenly;

[0056] In the third step, the deionized water aqueous solution of the second step is added to the deionized water aqueous solution of the first step under constant stirring, and stirred at room temperature for 40 minutes to ensure complete reaction;

[0057] In the fourth step, the reaction product is repeatedly washed with water or absolute ethanol until the solution is clear and dried in the shade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com