A method for synthesizing bipo4 micro- and nano-powders in ultrasonic liquid phase

A technology of micron powder and solution, applied in micro/nano material preparation, nano powder, ultrasonic liquid phase synthesis of BiPO4 micro field, to achieve the effect of less by-products, convenient and concise product processing, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Preparation of rice grain BiPO 4 Micron powder

[0025] Take 1mmol Bi(NO 3 ) 3 ·5H 2 O was placed in a 50ml Erlenmeyer flask, and 10ml of tetrahydrofuran and 5ml of absolute ethanol were added, placed on a magnetic stirrer and continuously stirred for 15min to dissolve it. Take 3mmol NaH again 2 PO 4 2H 2 O and 0.1g CTAB were added to the above solution and stirred for 15min. Then take out the stirring bar, place the Erlenmeyer flask in an ultrasonic cleaner, adjust the power to 80%, and carry out ultrasonic treatment for 1 hour. Pour the sonicated solution into a centrifuge tube and wash repeatedly with absolute ethanol and deionized water. After several times, take out the precipitate and place it in a constant temperature drying oven. Set the drying temperature to 80°C for 6 hours, that is, A white product is obtained.

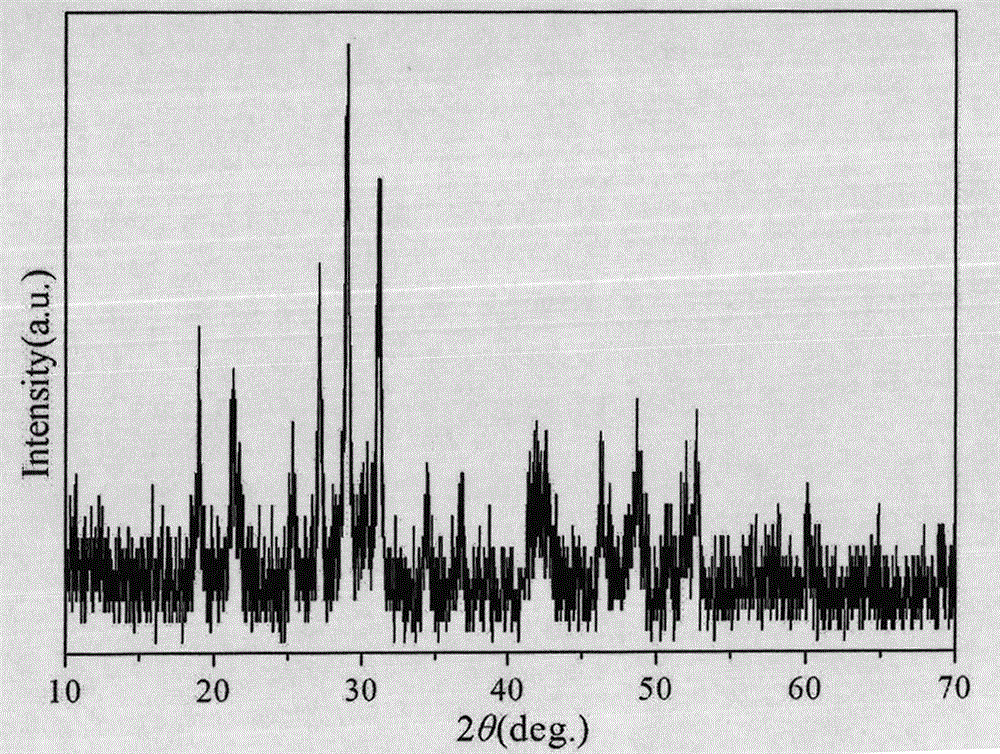

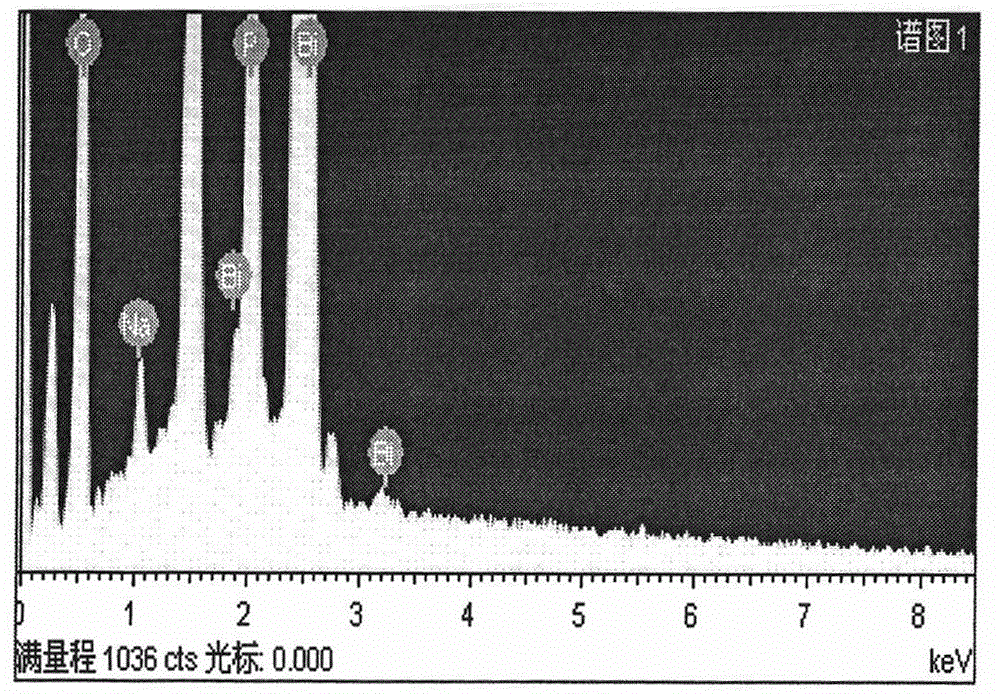

[0026] figure 1 The XRD pattern of the obtained product is given. As shown in the figure, the diffraction peaks at 2θ=19.09...

Embodiment 2

[0027] Example 2: Preparation of spherical BiPO 4 Nano powder

[0028] Take 1mmol Bi(NO 3 ) 3 ·5H 2 O was placed in a 50ml Erlenmeyer flask, and 10ml of tetrahydrofuran and 5ml of absolute ethanol were added, placed on a magnetic stirrer and continuously stirred for 15min to dissolve it. Take 3mmol NaH again 2 PO 4 2H 2 O and 0.1 g PEG were added to the above solution and stirred for 15 min. Then take out the stirring bar, place the Erlenmeyer flask in an ultrasonic cleaner, adjust the power to 80%, and carry out ultrasonic treatment for 60 minutes. Pour the sonicated solution into a centrifuge tube and wash repeatedly with absolute ethanol and deionized water. After several times, take out the precipitate and place it in a constant temperature drying oven. Set the drying temperature to 80°C for 6 hours, that is A white product is obtained.

[0029] Such as Figure 5 As shown in (a) and (b), when PEG is used as a surfactant, the BiPO obtained after ultrasonic reactio...

Embodiment 3

[0030] Example 3: Preparation of fusiform BiPO 4 Micron powder

[0031] Take 1mmol Bi(NO 3 ) 3 ·5H 2 O was placed in a 50ml Erlenmeyer flask, and 15ml of deionized water was added, placed on a magnetic stirrer and continuously stirred for 15min to dissolve it. Take 3mmol NaH again 2 PO 4 2H 2 O was added to the above solution and stirred for 15 min. Then take out the stirring bar, place the Erlenmeyer flask in an ultrasonic cleaner, adjust the power to 80%, and carry out ultrasonic treatment for 60 minutes. Pour the sonicated solution into a centrifuge tube and wash repeatedly with absolute ethanol and deionized water. After several times, take out the precipitate and place it in a constant temperature drying oven. Set the drying temperature to 80°C for 6 hours, that is A white product is obtained.

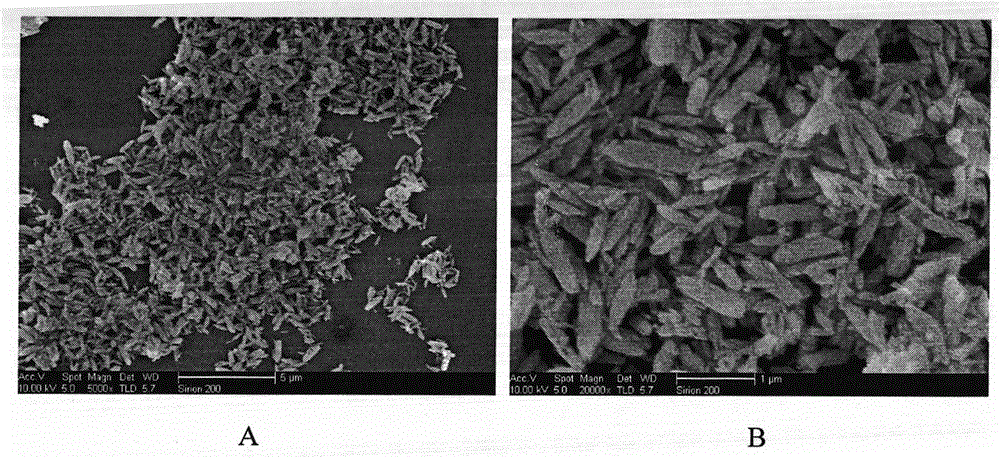

[0032] Such as Figure 6 As shown in (a) and (b), when 15ml deionized water is used as the solvent, the BiPO obtained after ultrasonic reaction 4 It presents a regular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com