Three-stage sludge treatment conveyor

A sludge treatment and conveying device technology, which is applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as too late treatment, environmental pollution, and reduced sludge treatment efficiency, and achieve shortening The effect of improving time and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

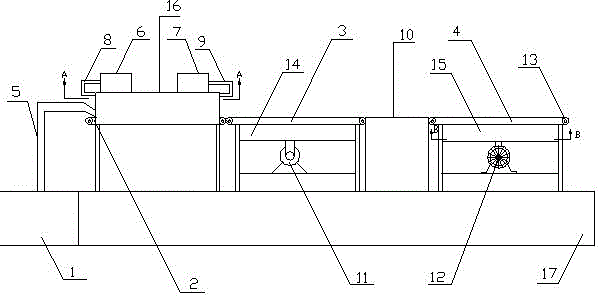

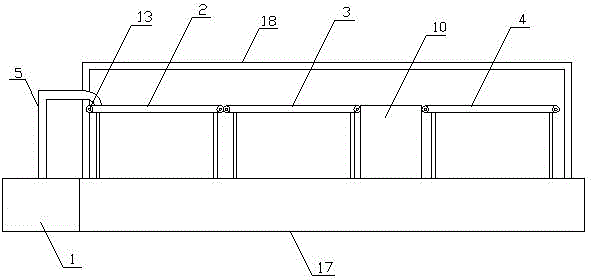

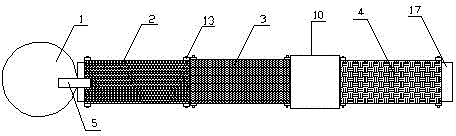

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] Refer to attached Figure 1-5 The three-stage sludge treatment conveyor belt shown includes a sludge tank 1, a first conveyor belt 2, a second conveyor belt 3 and a third conveyor belt 4, and the sludge on the first conveyor belt 2 is deodorized and disinfected , so polypropylene filter cloth is used, which has a smooth surface and good water permeability. The sludge on the second conveyor belt 3 needs to be digested aerobically. Therefore, a synthetic fiber ventilation pipe belt is used, which has good air permeability. The sludge on the conveyor belt 4 needs to be dried, so a polyester mesh belt is used, which has strong heat resistance, and each conveyor belt is equipped with a motor to drive the conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com