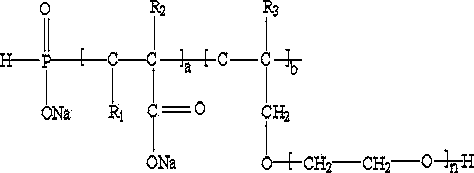

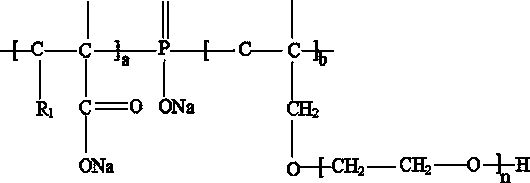

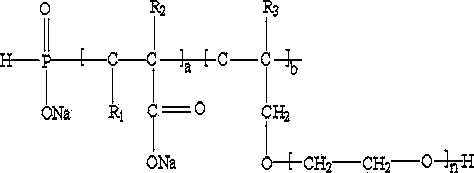

Phosphino-carboxylic acid water reducing agent and preparation method thereof

A technology of water reducing agent and phosphine carboxylic acid, which is applied in the field of phosphine carboxylic acid water reducing agent and its preparation, can solve the problems of no water reducing performance, cannot be used alone, cannot guarantee concrete construction quality, etc., and achieves good water reduction. Performance and slump retention, the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 245g of water and 320g of macromonomer isopentenyl polyethylene glycol ether into a 1000ml four-neck flask equipped with an electric stirring device, a constant temperature electric heating mantle, and a peristaltic pump. The molecular weight of the isopentenyl polyethylene glycol ether used is 1000~ 2500; stir and heat up to 60°C, add 3g of phosphorus-containing compound sodium hypophosphite, stir and dissolve evenly; within 2 hours, add dropwise a mixed aqueous solution consisting of 42g of acrylic acid and 30g of water and a mixture of 2g of ammonium persulfate and 50g of water Mix the aqueous solution at a temperature between 60°C and 62°C; after the dropwise addition, continue to react for 3 hours; then, lower the temperature to 35°C to 40°C, add 40% sodium hydroxide solution and dilution water to obtain a pH value equal to 7 40% phosphonic acid superplasticizer.

Embodiment 2

[0027] Add 245g of water and 320g of macromonomer methacryl polyethylene glycol ether into a 1000ml four-neck flask equipped with an electric stirring device, a constant temperature electric heating mantle, and a peristaltic pump, and the molecular weight of the methacryl polyethylene glycol ether used is 1000~ 2500; stir and heat up to 60°C, add 3g of phosphorus-containing compound sodium hypophosphite, stir and dissolve evenly; within 2 hours, add dropwise a mixed aqueous solution consisting of 42g of acrylic acid and 30g of water and a mixture of 2g of ammonium persulfate and 50g of water Mix the aqueous solution at a temperature between 60°C and 62°C; after the dropwise addition, continue to react for 3 hours; then, lower the temperature to 35°C to 40°C, add 40% sodium hydroxide solution and dilution water to obtain a pH value equal to 7 40% phosphonic acid superplasticizer.

Embodiment 3

[0029] Add 245g of water and 320g of macromonomer isopentenyl polyethylene glycol ether into a 1000ml four-neck flask equipped with an electric stirring device, a constant temperature electric heating mantle, and a peristaltic pump. The molecular weight of the isopentenyl polyethylene glycol ether used is 1000~ 2500; Stir and heat up to 70°C, add 3.5g of phosphorus-containing compound potassium hypophosphite, stir and dissolve evenly; within 2.5 hours, add dropwise a mixed aqueous solution consisting of 50.17g of methacrylic acid and 30g of water and 2.5g of sodium persulfate , 50g water mixed aqueous solution, the temperature is between 70 ℃ ~ 72 ℃; after the dropwise addition is completed, continue to react for 2 hours; then, lower the temperature to 35 ℃ ~ 40 ℃, add 40% sodium hydroxide solution and dilution water, get Phosphine carboxylic acid superplasticizer with PH value equal to 7 concentration and 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com