Self-cleaning waterproof sunshade fabric and preparation method thereof

A self-cleaning and fabric technology, applied in the field of textiles, can solve the problems of reduced fabric aging resistance, poor adhesion of the bottom layer, poor resistance to organic solvents, etc., and achieve excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of self-cleaning waterproof sunshade fabric of the present invention, its step is described in detail as follows:

[0033] Preparation of the fabric layer: wash the dope dyed fabric with water to remove the spinning oil on the fiber surface or the pollutants on the fabric surface, the pollutants include dust, etc. The specific process may include the following steps: Water washing → pressing roller to remove excess water → drum drying;

[0034] Preparation of resin layer and hydrophilic nano titanium dioxide layer:

[0035] First, apply a resin thickening solution with a resin content of 20% to 55% on the front of the above-mentioned dope-dyed fabric by scraping or roller coating to form a wet resin film, and the coating amount is 20g / m 2 ~150g / m 2 ;

[0036] Secondly, spray nano-titanium dioxide colloidal emulsion with a titanium dioxide nanoparticle content of 0.5% to 5% on the surface of the above-mentioned wet resin coating to form a nano-t...

Embodiment 1

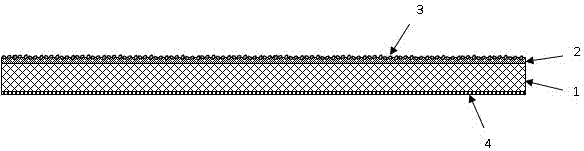

[0044] The high weather resistance dope dyed acrylic fabric is selected as the fabric layer 1, and the preparation steps of the fabric layer are as follows: the high weather resistance dope dyed acrylic fabric is washed with water to remove the spinning oil on the surface of the fiber, as well as dust and other pollutants on the surface of the fabric. The process is: padding with water washing aid solution à washing with water à pressing roller to remove excess water à drum drying.

[0045] Preparation of the resin layer 2 and the hydrophilic nano-titanium dioxide layer 3: apply the silicone-modified polyacrylic acid resin thickening solution with a solid content of 45% on the front of the dope-dyed acrylic fabric by scraping to form a resin wet film , the coating amount is 70g / m 2 . Before the dosing dyed acrylic fabric loaded with resin wet film after coating enters the setting machine oven, the hydrophilic nano-titanium dioxide colloidal emulsion with a titanium dioxide na...

Embodiment 2

[0048] The dope dyed polyester fabric with high weather resistance is selected as the fabric layer 1, and the preparatory steps of the fabric layer are as described in Example 1.

[0049] Preparation of resin layer 2 and nano-titanium dioxide layer 3: Coat the silicone-modified polyacrylic resin thickening solution (solid content: 45%) on the front side of the dope-dyed polyester fabric by scraping, and the coating amount is 80g / m 2 . Before the coated dope dyed polyester fabric carrying the resin wet film enters the oven of the setting machine, the hydrophilic nano-titanium dioxide colloidal emulsion with a titanium dioxide nanoparticle content of 4% is sprayed on the surface of the above-mentioned resin wet film, Among them, the spraying amount (dry) of titanium dioxide nanoparticles is 3g / m 2 . Then, the dope-dyed acrylic fabric loaded with the resin wet film and nano-titanium dioxide wet film was baked in an oven at a temperature of 155°C for 90 seconds. A silicone-mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com