Polyether sulfone water-based sizing agent and preparation method thereof

A sulfone water-based, polyether sulfone technology is applied in the field of polyether sulfone water-based sizing agent and its preparation method, which can solve the problem of affecting the interface bonding strength and overall performance of composite materials, increasing the processing cost of sizing agent and carbon fiber, and being unfavorable for subsequent fiber processing. and other problems, to achieve the effect of good industrialization prospects, easy to repeat implementation, simple and reliable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

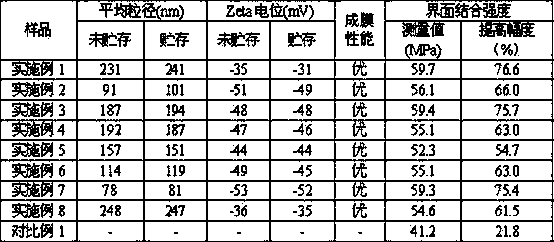

Examples

Embodiment 1

[0028] Weigh 100g of polyethersulfone resin with brand name A-300 from Solvay, USA, add it into 265ml of dimethylformamide, and dissolve to prepare a polyethersulfone solution. Then weigh 40g of Tween 80 and add it to 19.61L of deionized water, raise the temperature of the system to 60°C, use an emulsifier to mix at a high speed of 8000rpm for 30min, and then cool to room temperature to obtain an aqueous emulsion of emulsifier. Add the prepared polyethersulfone solution into the emulsifier aqueous emulsion at a system temperature of 40°C and an emulsification speed of 8000 rpm, mix at high speed for 30 minutes, and cool to room temperature to obtain a polyethersulfone water-based sizing agent.

[0029] The mass fraction of the main size in the sizing agent is 0.5%, the mass fraction of dimethylformamide is 1.3%, the mass fraction of emulsifier Tween 80 is 0.2%, and the mass fraction of deionized water is 98.0%.

Embodiment 2

[0031] Weigh 100 g of polyethersulfone resin with brand E2010 from BASF, Germany, add it into 268 ml of dimethylacetamide, and dissolve to prepare a polyethersulfone solution. Weigh 100g of Span 80 and add it to 4.55L of deionized water, raise the temperature of the system to 80°C, use an emulsifier to mix at a high speed of 12000rpm for 60min, and then cool to room temperature to obtain an aqueous emulsion of emulsifier. Add the prepared polyethersulfone solution into the emulsifier aqueous emulsion at a system temperature of 80°C and an emulsification speed of 12,000 rpm, mix at high speed for 60 minutes, and cool to room temperature to obtain a polyethersulfone water-based sizing agent.

[0032] The mass fraction of the main size in the sizing agent is 2.0%, the mass fraction of dimethylacetamide is 5.0%, the mass fraction of emulsifier Span 80 is 2.0%, and the mass fraction of deionized water is 91.0%.

Embodiment 3

[0034] Weighed 100 g of polyethersulfone resin with brand name E3010 from BASF, Germany, and added it into 318 ml of dimethylformamide, and dissolved it to prepare a polyethersulfone solution. Weigh 50g of Span 60 and add it to 9.55L of deionized water, raise the temperature of the system to 50°C, use an emulsifier to mix at a high speed of 9000rpm for 40min, and then cool to room temperature to obtain an aqueous emulsion of emulsifier. Add the prepared polyethersulfone solution into the aqueous emulsion of emulsifier under the conditions of system temperature 60°C and emulsification speed 10000rpm, mix at high speed for 45min, and cool to room temperature to obtain polyethersulfone water-based sizing agent.

[0035] The mass fraction of the main slurry in the sizing agent is 1.0%, the mass fraction of dimethylformamide is 3.0%, the mass fraction of emulsifier Span 60 is 0.5%, and the mass fraction of deionized water is 95.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com