Nitric oxide gas sensitive material manufacturing method, sensor, monitoring device and control method

A technology of nitrogen oxides and gas-sensitive materials, applied in electrical control, material resistance, engine control, etc., can solve the problems of reducing contact area, cracking, separation, etc., and achieve the goal of shortening sampling time, increasing sampling speed, and reducing volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

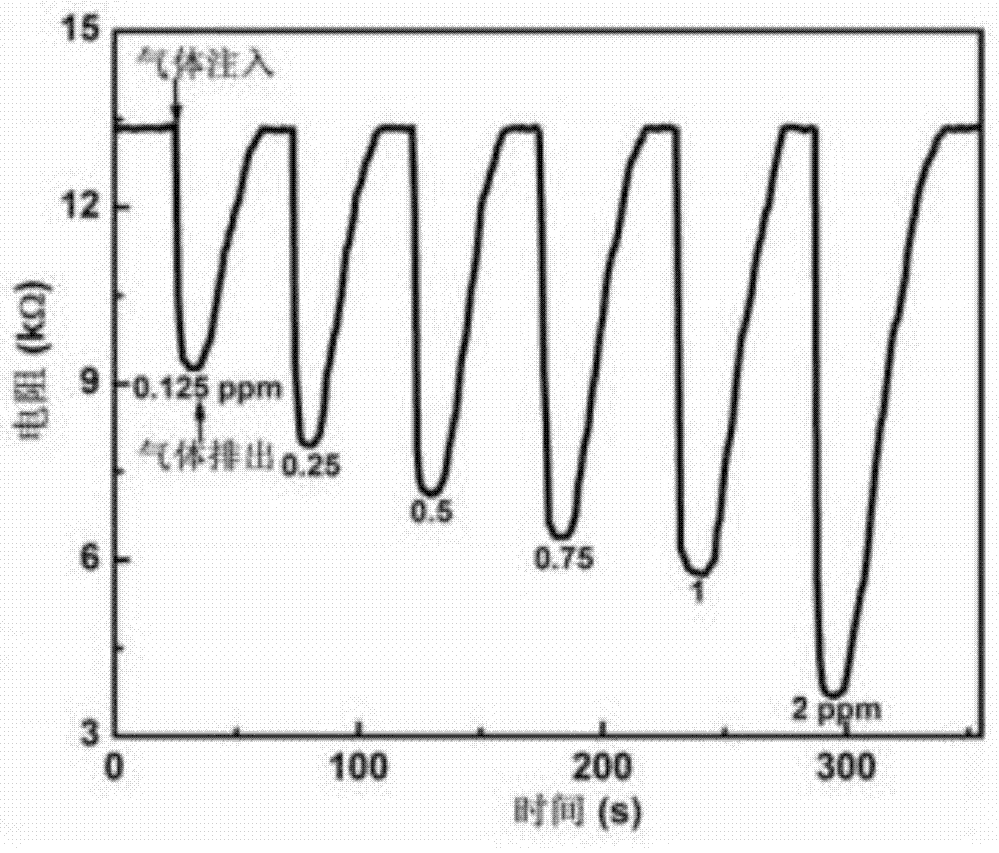

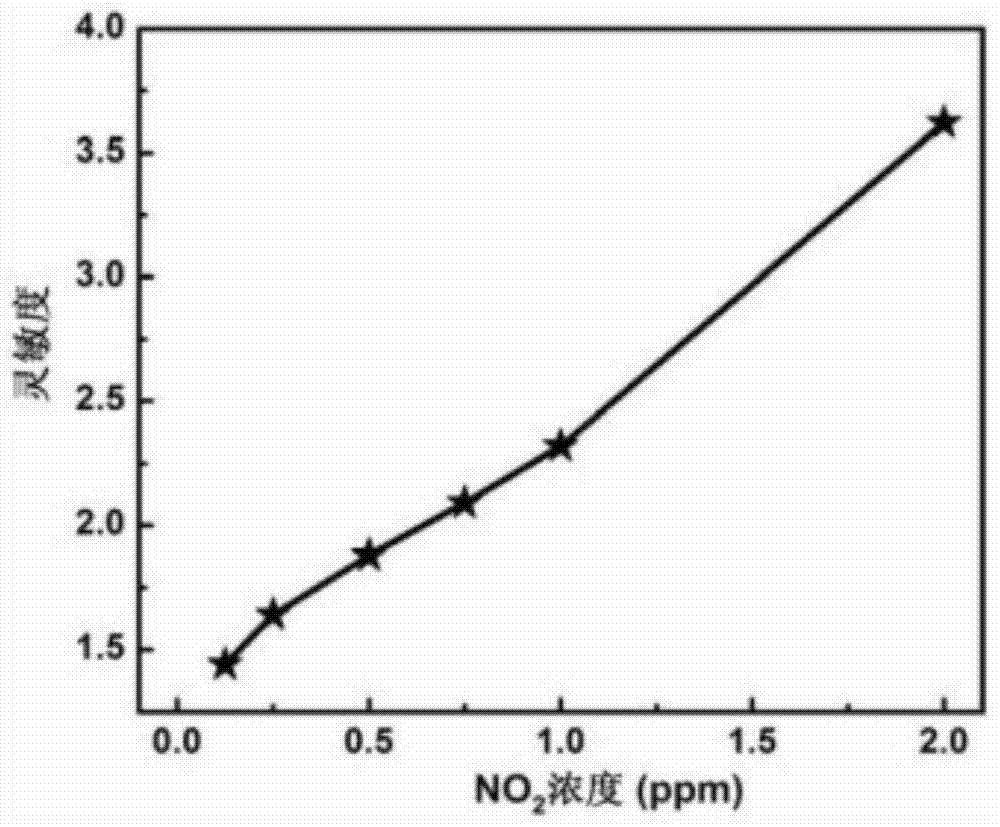

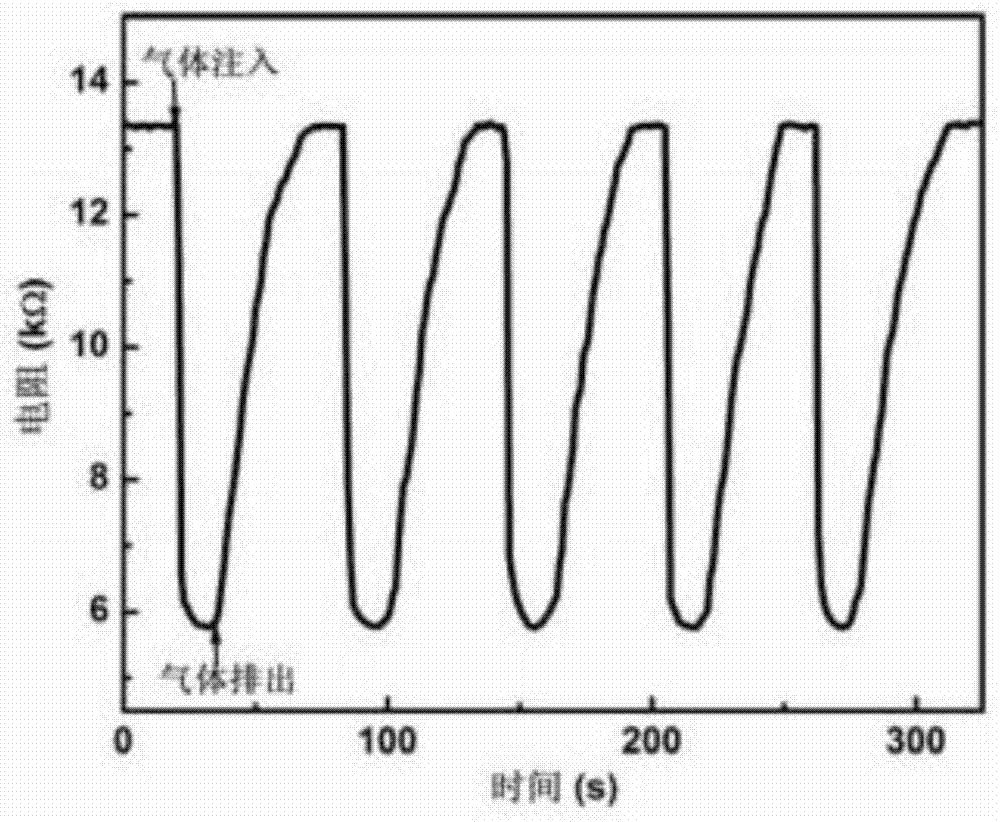

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention will be further described.

[0033] (1) Collect Na with ethanol 2 WO 4 The effluent of the solution, and electromagnetic stirring at 40 ° C to make the ethanol volatilize until the concentration of tungstic acid reaches about 0.5mol / dm 3 , and then dropwise add polyethylene glycol (PEG) 200 while stirring until WO 3 The mass ratio of polyethylene glycol / polyethylene glycol is 1:1, and a light yellow sol is obtained; after being stored at room temperature for three days, it is volatilized under reduced pressure at 100°C to obtain a gel; , Burn at 550°C and 650°C for 3 hours, the heating rate is ≤1.5°C / min, to ensure that ethanol and polyethylene glycol (PEG) 200 are fully volatilized and reduce carbon residue; after cooling, fully grind and refine, that is, WO 3 Nano powder;

[0034] (2) Prepare 0.1mol / dm 3 Dilute 100mL of this solution with 50mL of distilled water, stir it electromagnetically for 10min, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com