Method for manufacturing mixed-type supercapacitor in ink-jet printing mode

A technology of hybrid capacitors and supercapacitors, applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of energy density defects of hybrid capacitors, low utilization rate of active materials, uneven distribution of active materials, etc., to achieve high energy Density, loose pore size and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

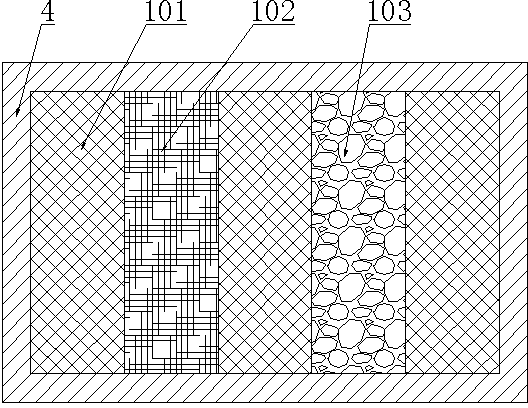

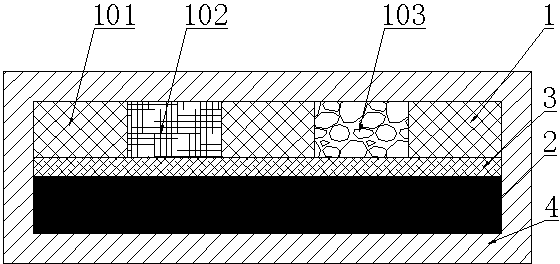

[0045] As shown in the figure, the hybrid supercapacitor has a casing 4, and the casing 4 is provided with a positive electrode 1, a negative electrode 2, and a separator 3 arranged between the positive electrode 1 and the negative electrode 2, and the positive electrodes are sequentially arranged from left to right It is composed of conductive carbon black-conductive graphite carbon electrode material electrode 101, lithium battery positive electrode material electrode 102, conductive carbon black-conductive graphite carbon electrode material electrode 101, metal oxide material electrode 103 and conductive carbon black-conductive graphite carbon electrode material electrode 101. .

[0046] 1. Preparation of carbon electrode materials

[0047] 1.1. Preparation of Ketjen black slurry

[0048] Mix 2 g of Ketjen black with 2 g of deionized water, stir for 15 minutes, and prepare a Ketjen black slurry;

[0049] 1.2. Preparation of conductive agent

[0050] Mix 9.6g of Ketjen bl...

Embodiment 2

[0077] As shown in the figure, the structure of the hybrid supercapacitor is the same as that of Example 1;

[0078] 1. Preparation of carbon electrode materials

[0079] 1.1. Preparation of Ketjen black slurry

[0080] Mix 2 g of Ketjen black with 3 g of deionized water, stir for 30 min, and prepare a Ketjen black slurry;

[0081] 1.2. Preparation of conductive agent

[0082] Mix 10.4g Ketjen black, 2g conductive graphite and 8g conductive carbon black evenly to prepare a conductive agent;

[0083] 1.3. Preparation of sodium carboxymethyl cellulose colloidal solution

[0084] Add 0.2 g of sodium carboxymethyl cellulose into 9.8 g of deionized water and mix well to prepare a sodium carboxymethyl cellulose colloidal solution;

[0085] 1.4. Preparation of styrene-butadiene rubber emulsion

[0086] Add 8g of styrene-butadiene rubber to 12g of deionized water to prepare a styrene-butadiene rubber emulsion;

[0087] 1.5. Preparation of carbon electrode material slurry

[008...

Embodiment 3

[0109] As shown in the figure, the structure of the hybrid supercapacitor is the same as that of Example 1;

[0110] 1. Preparation of carbon electrode materials

[0111] 1.1. Preparation of Ketjen black slurry

[0112] Mix 2 g of Ketjen black with 2.4 g of deionized water, and stir for 20 minutes to prepare a Ketjen black slurry;

[0113] 1.2. Preparation of conductive agent

[0114] Mix 10g Ketjen black, 2g conductive graphite and 7.6g conductive carbon black evenly to prepare a conductive agent;

[0115] 1.3. Preparation of sodium carboxymethyl cellulose colloidal solution

[0116] Add 0.25 g of sodium carboxymethyl cellulose into 9.75 g of deionized water and mix well to prepare a sodium carboxymethyl cellulose colloidal solution;

[0117] 1.4. Preparation of styrene-butadiene rubber emulsion

[0118] Add 8g of styrene-butadiene rubber to 10g of deionized water to prepare a styrene-butadiene rubber emulsion;

[0119] 1.5. Preparation of carbon electrode material slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com