Multi-state Gallium Antimony-Stin Selenide Multilayer Nanocomposite Phase Change Material and Its Preparation and Application

A nano-composite, phase-change material technology, applied in the field of microelectronic materials, can solve the problem that the power consumption of phase-change memory devices is not too large, and achieve improved thermal stability, high crystalline and amorphous resistance, The effect of increasing storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

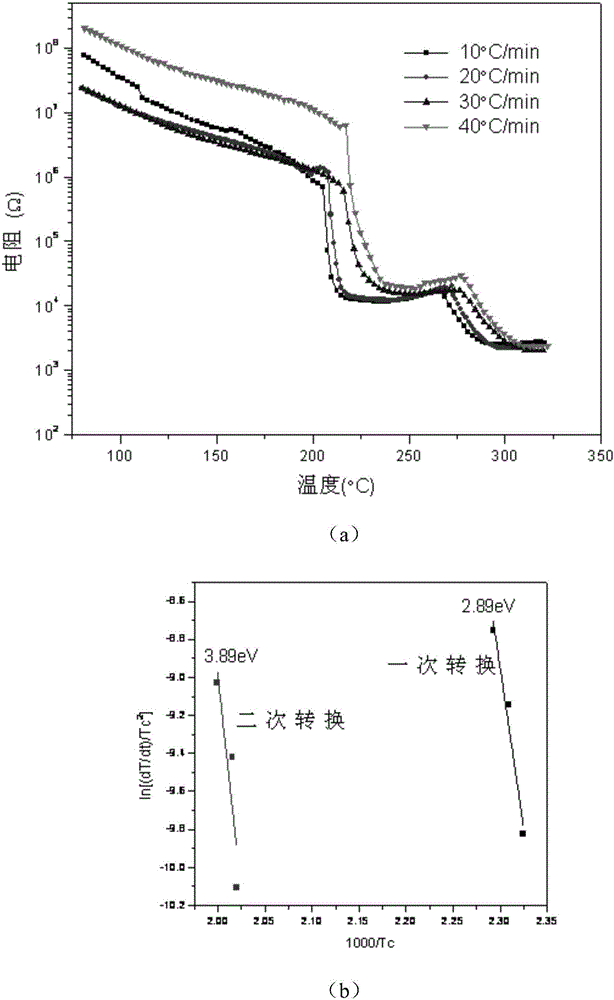

[0049] Ga prepared in this example 30 Sb 70 / SnSe 2 The total thickness of the nanocomposite multilayer phase change film is 50nm, and the specific structure is [Ga 30 Sb 70 (10nm)SnSe 2 (15nm)] 2.

[0050] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities:

[0051] (a) Place the substrate in an ethanol solution, and clean it ultrasonically for 15 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0052] (b) The substrate is placed in an acetone solution, and ultrasonically cleaned for 15 minutes to remove organic impurities on the surface of the substrate;

[0053] (c) Place the substrate in deionized water, clean it ultrasonically for 15 minutes, and clean the surface again;

[0054] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0055] 2. Prepared by sputtering method [Ga 30 Sb 70 (10nm)SnSe 2 (15nm)] 2 film preparation

[0056] (a) put...

Embodiment 2

[0065] Ga prepared in this example30 Sb 70 / SnSe 2 The total thickness of the nanocomposite multilayer phase change film is 50nm, and the specific structure is [Ga 30 Sb 70 (25nm)SnSe 2 (25nm)]1.

[0066] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities:

[0067] (a) Place the substrate in an ethanol solution, and clean it ultrasonically for 15 minutes to remove dust particles and inorganic impurities on the surface of the substrate;

[0068] (b) The substrate is placed in an acetone solution, and ultrasonically cleaned for 15 minutes to remove organic impurities on the surface of the substrate;

[0069] (c) Place the substrate in deionized water, clean it ultrasonically for 15 minutes, and clean the surface again;

[0070] (d) Take out the substrate, dry it with pure Ar gas, and set it aside.

[0071] 2. Prepared by sputtering method [Ga 30 Sb 70 (25nm)SnSe 2 (25nm)] 1 film preparation

[0072] (a) put Ga...

Embodiment 3

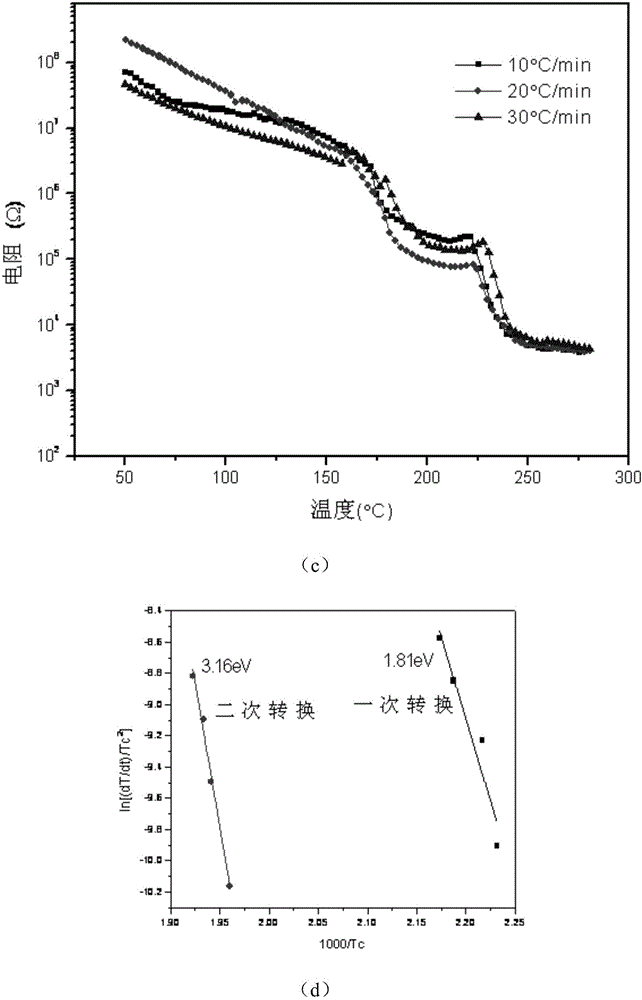

[0111] Polymorphic gallium antimony-tin selenide multilayer nanocomposite phase change material, Ga 30 Sb 70 / SnSe 2 Nanocomposite multilayer phase change films made of SnSe 2 thin film and Ga 30 Sb 70 The films are alternately arranged into a multilayer film structure, in which the SnSe 2 The thickness of the film is 5nm, Ga 30 Sb 70 The thickness of the film is 5nm; it consists of 5 layers of periodically repeating structure, Ga 30 Sb 70 / SnSe 2 The total thickness of the nanocomposite multilayer phase change film is 50nm, Ga 30 Sb 70 / SnSe 2 The nanocomposite multilayer phase change film has three storage states.

[0112] The multi-state gallium antimony-tin selenide multilayer nanocomposite phase change material was prepared by magnetron sputtering method. 2 / Si(100) substrate, with Ga 30 Sb 70 and SnSe 2 As the sputtering target, Ar gas was used as the sputtering gas to alternately deposit multiple layers of SnSe 2 thin film and Ga 30 Sb 70 Thin film, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com