Polydextrose with controllable molecular weight and rapid preparation method thereof

The technology of polydextrose and glucose is applied in the fields of molecular weight controllable polydextrose and its rapid preparation, edible dietary fiber and its preparation, and can solve the problems of affecting the taste application of polydextrose, uneven heating of reactants, uncontrollable molecular weight and the like, Achieve the effect of superior product performance, thorough polymerization reaction and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

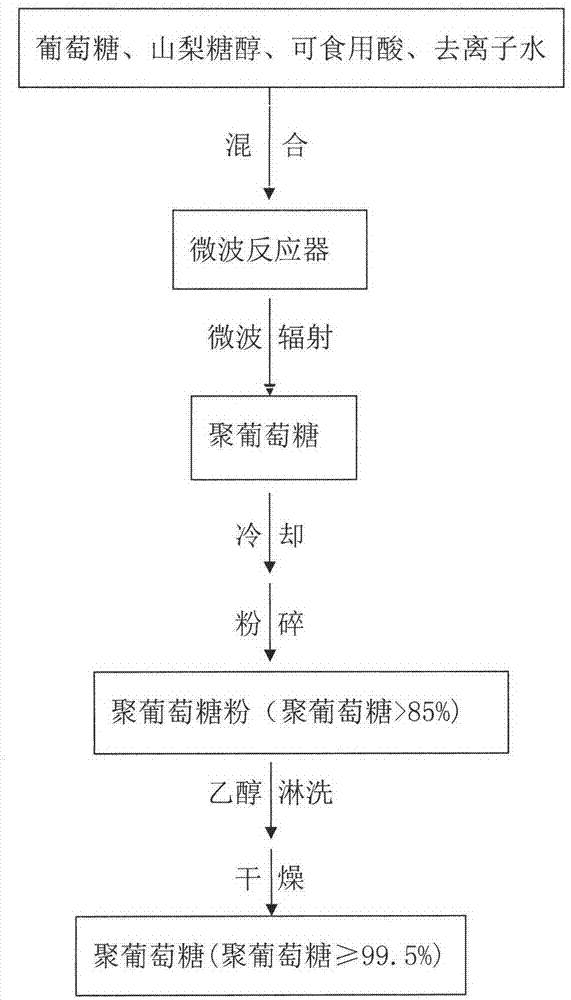

[0050] The production technology of embodiment 1 polydextrose

[0051] Food-grade glucose 8kg, food-grade citric acid monohydrate 0.4kg, food-grade D-sorbitol 0.5kg, deionized water 1.1kg, mix evenly with a dry powder mixer, enter the microwave reactor, where the microwave power is 950W, and the reaction temperature is 125~ 130°C, reaction time 2.5 minutes, cooling in dry air, and crushing to obtain polydextrose solid. 40L of 50% ethanol was rinsed, and the polydextrose after the rinse was concentrated and vacuum-dried to obtain 7.68 kg of polydextrose solid.

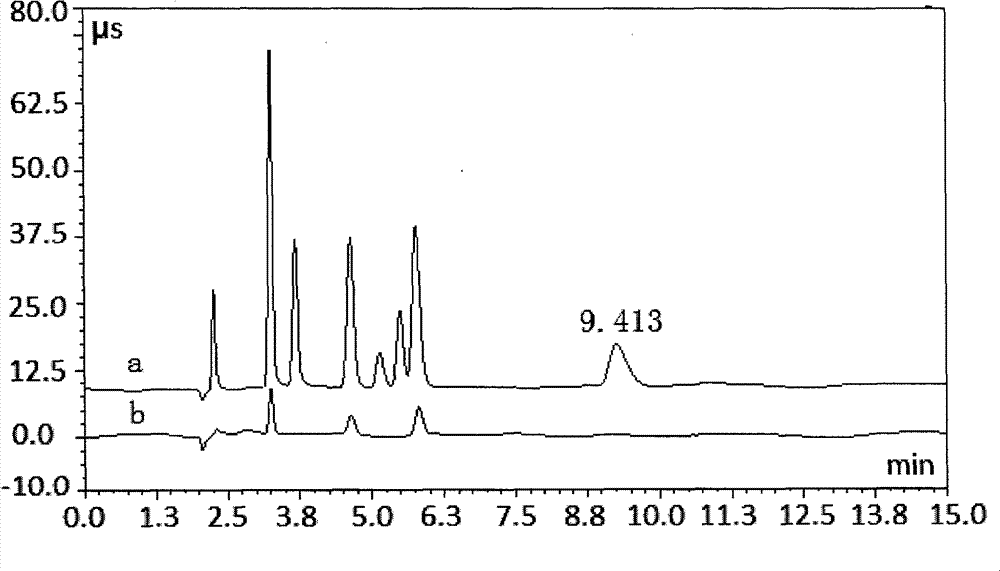

[0052] HPLC detection analysis, polydextrose content ≥ 99.5%, does not contain glucose, 5-hydroxymethylfurfural, sorbitol, citric acid.

[0053] Glucose, citric acid, and sorbitol were purchased from Jinan Shengfeng Industry and Trade Co., Ltd., Weifang Ensign Industrial Co., Ltd., and Roquette, respectively.

[0054] HPLC detection conditions: detection equipment: Agilent 1260 high performance liquid chromatography; ...

Embodiment 2

[0055] The production technology of embodiment 2 polydextrose

[0056] Food-grade glucose 9kg, food-grade citric acid monohydrate 0.03kg, food-grade D-sorbitol 0.1kg, deionized water 0.97kg, mix evenly with a dry powder mixer, enter the microwave reactor, where the microwave power is 800W, and the reaction temperature is 245~ 250°C, the reaction time is 1 minute, cooled in dry air, and pulverized to obtain polydextrose solid. 52L of 25% ethanol was rinsed, and the polydextrose after the rinse was concentrated and vacuum-dried to obtain 8.12 kg of polydextrose solid.

[0057] HPLC detection analysis, polydextrose content ≥ 99.5%, does not contain glucose, 5-hydroxymethylfurfural, sorbitol, citric acid.

[0058] Raw material sources and detection conditions are the same as those described in Example 1.

Embodiment 3

[0059] The production technology of embodiment 3 polydextrose

[0060] Food-grade glucose 7kg, food-grade citric acid monohydrate 0.5kg, food-grade D-sorbitol 0.5kg, deionized water 2kg, mix evenly with a dry powder mixer, enter the microwave reactor, where the microwave power is 900W, and the reaction temperature is 105-110 °C, the reaction time is 8 minutes, cooled in dry air, and pulverized to obtain polydextrose solid. 44 L of 80% ethanol was rinsed, and the polydextrose after the rinse was concentrated and vacuum-dried to obtain 6.53 kg of polydextrose solid.

[0061] HPLC detection analysis, polydextrose content ≥ 99.5%, does not contain glucose, 5-hydroxymethylfurfural, sorbitol, citric acid.

[0062] Raw material sources and detection conditions are the same as those described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com