A kind of high-strength polysaccharide gel microsphere, preparation method and application thereof

A gel microsphere, high-strength technology, applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems of low medium flow rate and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1 Preparation of 4wt% high-strength agarose microspheres by blending method

[0068] (1) Modification of agarose raw materials

[0069] Weigh 4g of agarose powder, add 40mL of water, heat to dissolve, get a 10% agarose solution, cool to about 65℃, slowly add 0.5mL of 40% NaOH solution and bifunctional crosslinker allyl glycidyl ether to it 6mL. Among them, the concentration of allyl glycidyl ether in the water phase is 15%, OH - The concentration is 0.21mol / L. After stirring and reacting at 65°C for 8 hours, the reaction was terminated by adjusting the pH value of 7-8 with 60% glacial acetic acid solution, and an allylated agarose solution was obtained. 4 times the volume of ethanol was added to the solution, the precipitate was collected by centrifugation, pre-frozen at -70°C for 2 hours, and freeze-dried for 72 hours to obtain modified agarose raw material.

[0070] (2) Blending to prepare agarose microspheres modified with crosslinker

[0071] Accurately weigh 1.2...

Embodiment 2

[0076] Example 2 Preparation of 4wt% high-strength agarose microspheres by blending method

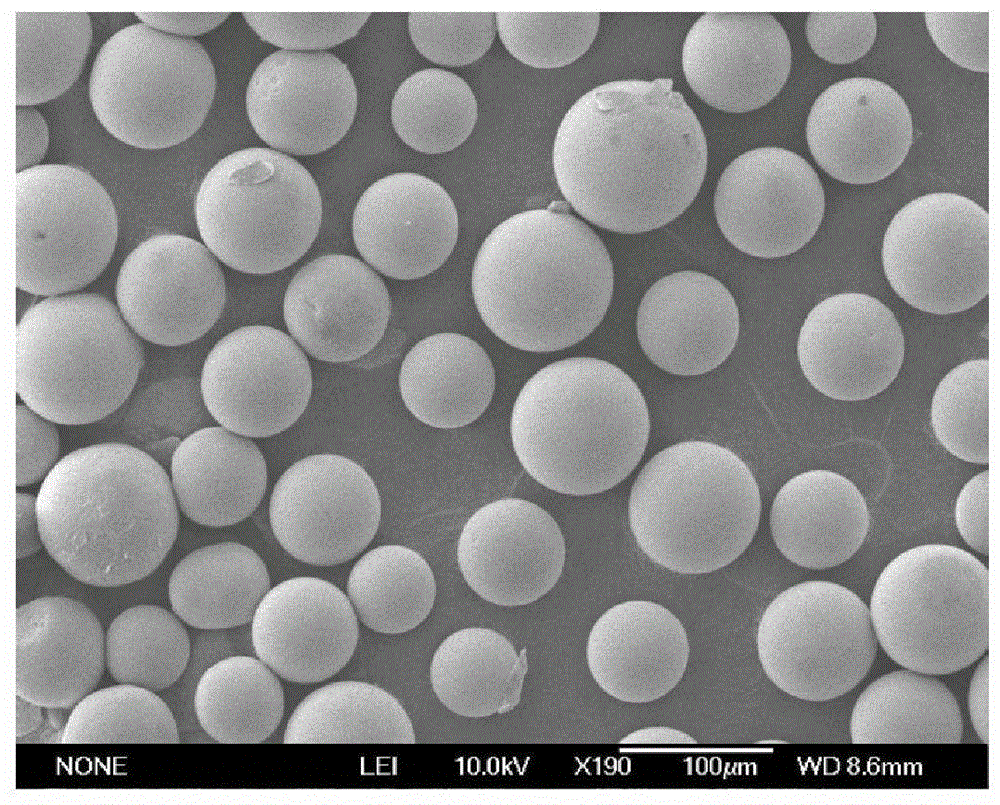

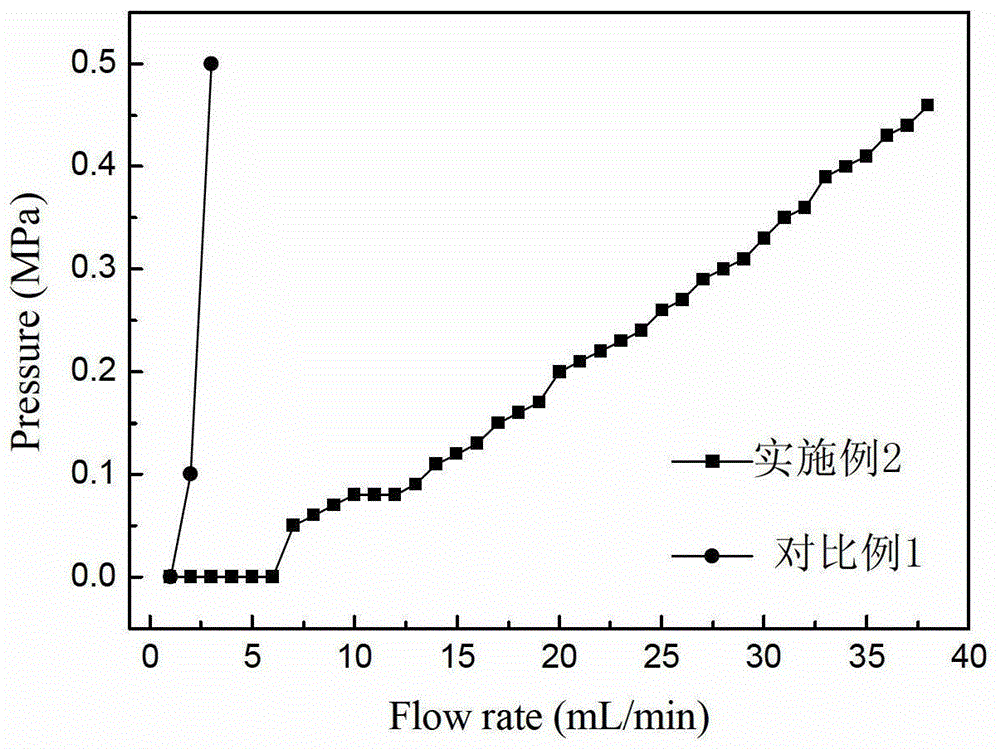

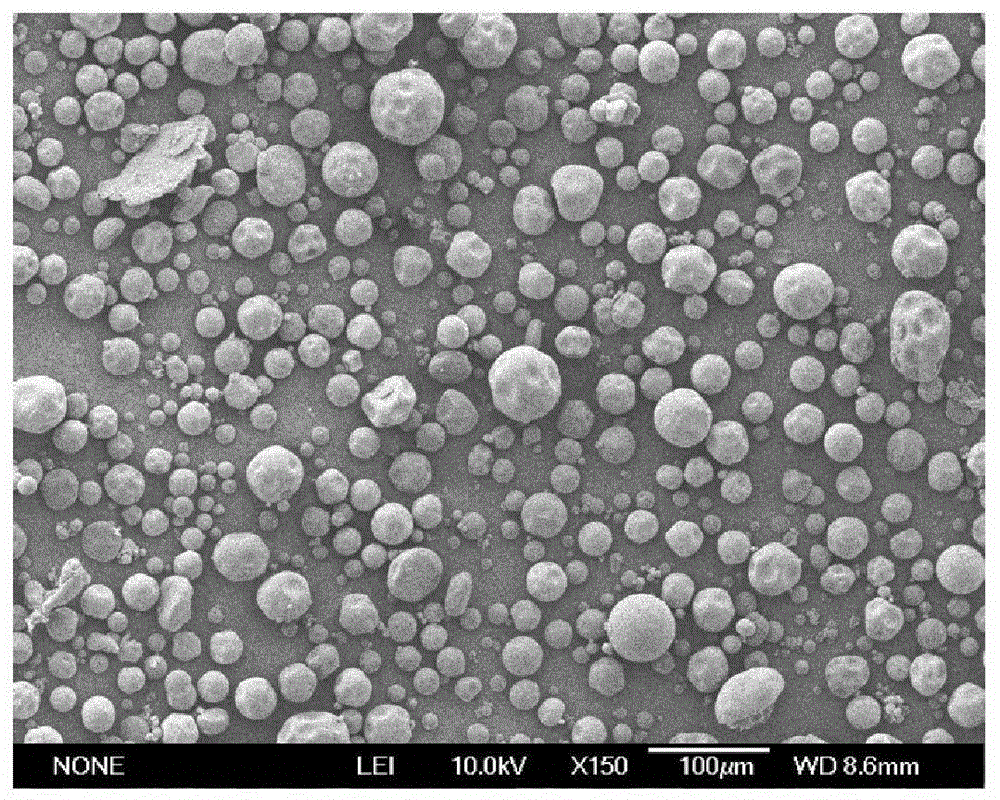

[0077] In order to further increase the strength of the agarose gel microspheres, on the basis of the cross-linking process described in Example 1, the traditional method is used to continue cross-linking once. That is, take 20 g of cross-linked agarose microspheres obtained in step (3) of Example 1 and disperse in 40 mL of deionized water, and gradually increase the temperature to 47.5° C. for 2 h. Then, slowly add 1.6mL epichlorohydrin and 2.4mL 40% NaOH solution (containing 3% NaBH 4 ), continue to react for 12h in a constant temperature water bath shaker. After the cross-linking is completed, wash with water to neutrality. The average particle size of the 4wt% highly cross-linked agarose microspheres obtained is 86.41μm, and the maximum flow rate in the linear range is 2980cm / h. The pressure flow rate curve is like figure 2 Shown.

Embodiment 3

[0087] Example 3 Preparation of 6wt% high-strength agarose microspheres by blending method

[0088] (1) Modification of agarose raw materials

[0089] Prepare 40 mL agarose solution with a concentration of 18%, cool to about 80°C, and slowly add 3 mL of 40% NaOH solution and 8 mL of crosslinker allyl glycidyl ether to it. Among them, the concentration of allyl glycidyl ether in the water phase is 20%, OH - The concentration is 1.25mol / L. After stirring and reacting at 80℃ for 3h, 60% glacial acetic acid solution was used to adjust the pH value of 7-8 to terminate the reaction, and an allylated agarose solution was obtained. 4 times the volume of ethanol was added to the solution, the precipitate was collected by centrifugation, pre-frozen at -70°C for 2 hours, and freeze-dried for 72 hours to obtain modified agarose raw material.

[0090] (2) Blending to prepare agarose microspheres modified with crosslinker

[0091] Accurately weigh 3.24g of modified agarose raw material (90% of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com