Preparation method of potassium-doped nano titanium dioxide photo-catalyst

A nano-titanium dioxide and photocatalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of high preparation cost and difficult practical application, and achieve The effect of low preparation cost, improved photocatalytic activity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Slowly add 20 mL of tetrabutyl titanate dropwise into 70 mL of absolute ethanol under stirring, then add 6.7 mL of acetylacetone and 15.4 mL of Triton X-100, then add 1 g of polyethylene glycol, continue Stir for 2 hours to obtain solution A; Add 0.1532g of potassium hydroxide to 8mL double distilled water, then add the water and ethanol mixture prepared according to the volume ratio of double distilled water and absolute ethanol at 1:3, and use 1:1 Adjust the pH value to 3 with hydrochloric acid, and stir for 0.2 hours to obtain solution B; slowly add solution B to solution A at a volume ratio of 1:3.2 between solution B and solution A, and continue stirring for 2 hours after the addition is complete. Stand and age naturally to gel. Pour the gel into the tray and dry it in an oven at 100°C. Grind the dry gel into powder and pour it into a crucible, put it in a muffle furnace, and heat it up to 550°C according to the program of 5°C / min for roasting 2.5h, then naturally...

Embodiment 2

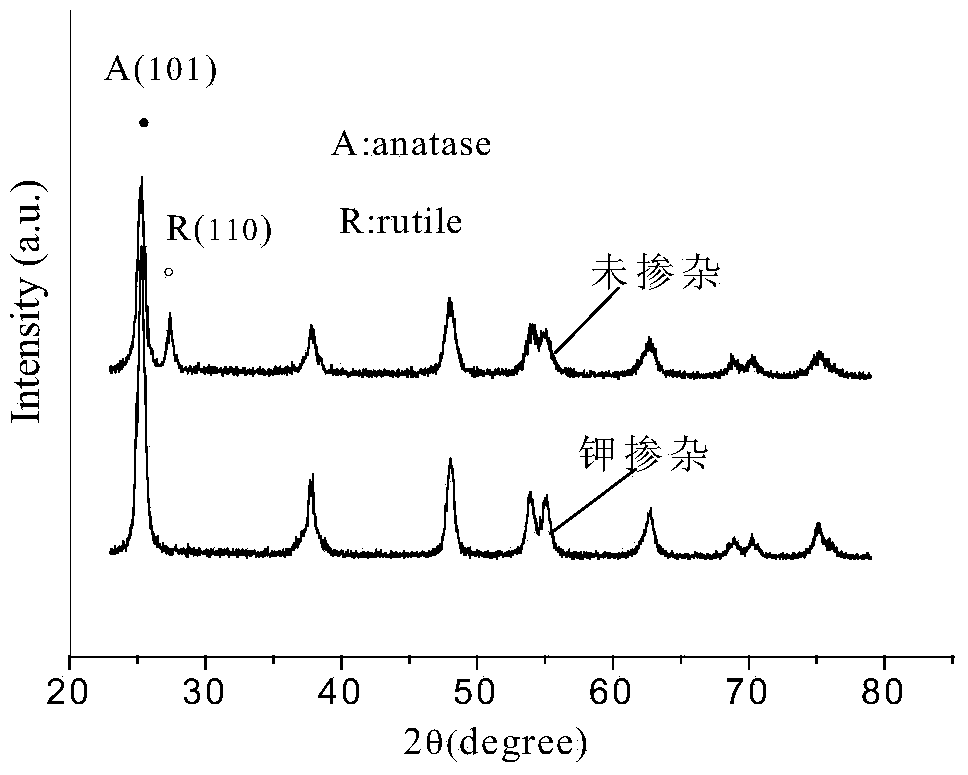

[0035] The difference between this embodiment and Example 1 is that the firing temperature is 650° C., and the others are the same as Example 1. The resulting potassium-doped nano-TiO 2 with undoped nano-TiO 2 For comparison of the X-ray (XRD) spectrum, see figure 1 .

[0036] From figure 1 It can be seen that for undoped TiO 2 , the rutile phase appeared in the crystal, while for doped TiO 2 , it can be seen that due to potassium doping, the 101 plane diffraction peak becomes sharper and stronger, and no rutile phase diffraction peak appears. show K + Doping prevents the generation of the rutile phase. XRD did not detect potassium oxide diffraction peaks, indicating that K + Fully incorporated and evenly dispersed into TiO 2 in the crystal lattice and form a solid solution with it. Potassium-doped nano-TiO was calculated according to the Scherrer formula 2 The grain size is 17.9nm, while undoped TiO 2 The particle size is 30.7nm, indicating that K + Doping suppre...

Embodiment 3

[0039] The difference between this embodiment and Example 1 is that the added potassium hydroxide is 0.2213g, and the potassium-doped nano-TiO with a doping concentration of 6.5% is obtained. 2 , others are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com