Method for solidifying ceramic slurry through controlling high-valent contra-ion by slowly adjusting pH value

A technology of ceramic slurry and counter ions, applied in the field of inorganic non-metallic ceramic curing, can solve the problems of complex coating process, and achieve the effects of high dimensional accuracy, short curing time and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

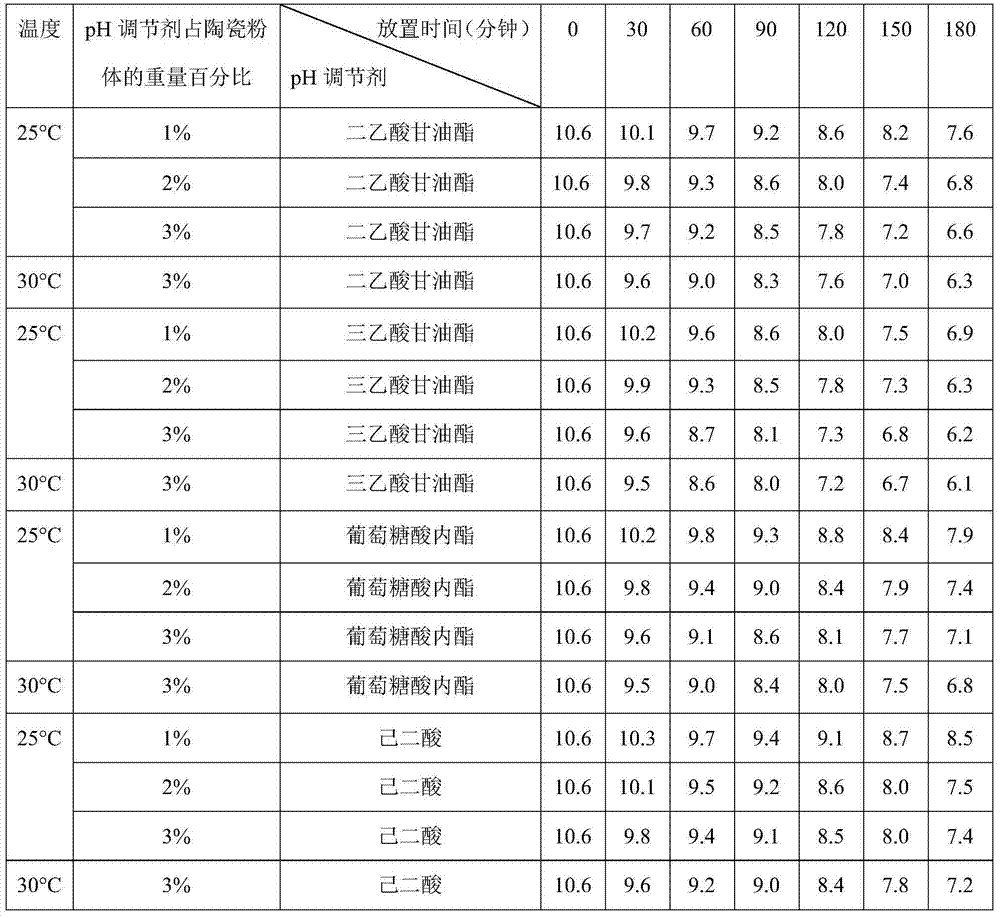

[0031] Embodiment 1: the selection of pH regulator

[0032] In order to overcome the defect that the conventional pH regulator adjusts the pH too quickly and partially solidifies the ceramic slurry, the present invention screens and obtains several pH regulators with the function of slowly adjusting the pH.

[0033] Mix the dispersant, water and ceramic powder evenly, wherein the mass of the dispersant is 0.1% to 2.5% of the mass of the ceramic powder, and after ball milling for 12 to 48 hours, a negatively charged ceramic slurry is obtained on the surface of the particles, and the pH regulator Diacetin, glyceryl triacetate, gluconolactone or adipic acid were added to the ceramic slurry, the initial pH value of the ceramic slurry was 10.6, and they were left standing at 25°C and 30°C respectively, and every Measure the pH value of the ceramic slurry once every 30 minutes. The test results are shown in Table 1. The above-mentioned pH regulator can slowly adjust the pH of the c...

Embodiment 2

[0037] Embodiment 2: Using calcium citrate as the method of direct solidification molding of alumina ceramic slurry as curing agent

[0038] The specific steps are the same as in Comparative Example 1, but by adding 2 grams of glyceryl diacetate as a pH regulator, stirring in a vacuum for 10 minutes to remove air bubbles, pouring it into a glass mold, and demolding it after standing at room temperature for 2 hours to obtain a ceramic wet body. The pH value of the slurry was lowered to 8, and dried at 80°C for 24 hours to obtain a dry body. The dry body was placed in an electric furnace, and the temperature was raised to 1550°C at a heating rate of 5°C per minute, and kept for 2 hours to obtain a ceramic sintered body.

Embodiment 3

[0039] Embodiment 3: the method for direct solidification molding of zirconia ceramic slurry using magnesium citrate as curing agent

[0040]305 grams of zirconia, 5 grams of ammonium polyacrylate and 50 grams of water were mixed and ball milled for 24 hours to prepare a ceramic slurry with a solid phase volume fraction of 50%. Add 2 grams of magnesium citrate and 3 grams of glyceryl triacetate, stir in vacuum for 10 minutes to remove air bubbles, inject it into a plastic mold, leave the mold at room temperature for 4 hours, and then demould to obtain a ceramic wet body. During this process, the pH value of the ceramic slurry is reduced to 6. Dry at 80°C for 24 hours to obtain a dry compact, place the dry compact in an electric furnace, raise the temperature to 1600°C at a rate of 5°C per minute, and keep the temperature for 1 hour to obtain a ceramic sintered body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com