Piperazine-modified phthalocyanine complex and preparation method thereof

A complex, piperazine technology, applied in the directions of medical preparations, pharmaceutical formulations, and drug combinations containing active ingredients, can solve the problems of difficult separation, many side reactions, and difficult synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

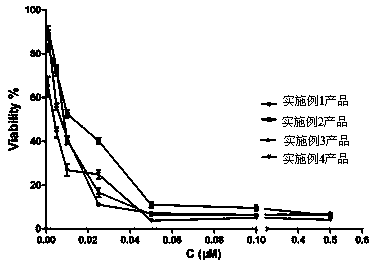

Examples

Embodiment 1

[0068] Embodiment 1 (Ia, R=C 2 h 5 )

[0069] 1) Add compound 1 (3.45 g, 0.03 mol) and compound 2 (5.04 g, 0.03 mol) into 30ml of acetonitrile, after the two are dissolved, add K 2 CO 3 (20.70 g, 0.15 mol), reacted at 85 °C under nitrogen protection for 12 h; after the reaction was completed, spin dry acetonitrile, add 100 ml water, extract with 500 ml dichloromethane, collect the organic layer, spin dry, and then distilled Chloromethane:methanol=30:1 was used as the eluent, and compound 3 (5.41 g) was obtained by gel column separation with a yield of 90%. 1 H NMR (400 MHz, CDCl 3 ): δ 1.00-1.10 (m, 3 H, CH 3 ), 1.20-1.30 (m, 3 H, CH 3 ), 2.38-2.46 (m, 2 H, CH 2 ), 2.46-2.66 (br s, 8 H, CH 2 ), 3.18-3.22 (m, 2 H, CH 2 ), 4.12-4.20 (m, 2 H, CH 2 ). HRMS (ESI): m / z C 10 h 21 N 2 o 2 [M+H] + , the calculated value is 201.1598; the measured value is 201.1604.

[0070] 2) Lithium aluminum hydride (LiAlH 4 ) (0.21 g, 0.006 mol) was added to a round-bottomed flask ...

Embodiment 2

[0073] Example 2 (IIa, R=C 2 h 5 )

[0074] 1) Add compound 1 (3.45 g, 0.03 mol) and compound 2 (5.04 g, 0.03 mol) into 30 ml of acetonitrile, after the two are dissolved, add K 2 CO 3 (20.70 g, 0.15 mol), and reacted for 12 h at 85 °C under the protection of nitrogen; after the reaction was completed, spin dry acetonitrile, add 100 ml water, extract with 500 ml dichloromethane, collect the organic layer, spin dry, and then distilled Chloromethane:methanol=30:1 was used as the eluent, and compound 3 (5.41 g) was obtained by gel column separation with a yield of 90%. 1 H NMR (400 MHz, CDCl 3 ): δ 1.00-1.10 (m, 3 H, CH 3 ), 1.20-1.30 (m, 3 H, CH 3 ), 2.38-2.46 (m, 2 H, CH 2 ), 2.46-2.66 (br s, 8 H, CH 2 ), 3.18-3.22 (m, 2 H, CH 2 ), 4.12-4.20 (m, 2 H, CH 2 ). HRMS (ESI): m / z C 10 h 21 N 2 o 2 [M+H] + , the calculated value is 201.1598; the measured value is 201.1604.

[0075] 2) Lithium aluminum hydride (LiAlH 4 ) (0.21 g, 0.006 mol) was added to a round-bott...

Embodiment 3

[0078] Embodiment 3 (If, R=(CH 2 CH 2 O) 3 CH 3 )

[0079] 1) Compound HO(CH 2 CH 2 O) 3 CH 3 (16.41 g, 0.1 mol) and compound (22.80 g, 0.12 mol) was added to dichloromethane, and after both were dissolved, triethylamine (15.18 g, 0.15 mol) was added and reacted for 12 h at room temperature under the protection of nitrogen; after the reaction was completed, the crude product was extracted with water , collecting the organic layer, followed by petroleum ether-ethyl acetate as eluent, separated by silica gel column to obtain the compound TsO(CH 2 CH 2 O) 3 CH 3 (27.04 g). The yield is 85% 【1】 .

[0080] 2) Compound TsO(CH 2 CH 2 O) 3 CH 3 (3.19 g, 0.01 mol) and compound (1.31 g, 0.01 mol) was added into 20 ml of acetonitrile at a molar ratio of 1:1, and after both were dissolved, K 2 CO 3 (6.90 g, 0.05 mol), reacted at 85 °C under nitrogen protection for 8-12 h; after the reaction was completed, spin dry acetonitrile, add 100 ml water, extract the crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com