Filtered juice clarification method by saturated filling of flue gas

A technology for flue gas and juice filtration, which is applied in the direction of purification using alkaline earth compounds, can solve the problems affecting product quality, turbidity and coloring of filtered juice, etc., and achieve the effect of improving sugar recovery rate, less non-sugar impurities, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

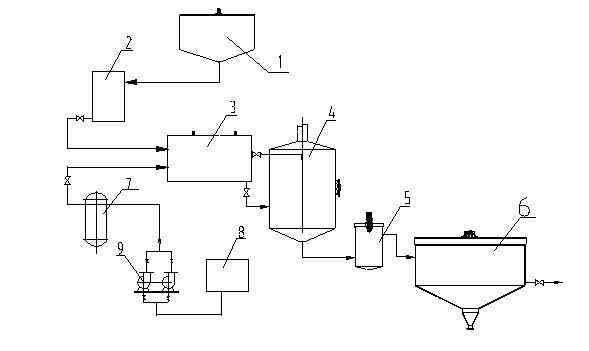

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0015] The flue gas at the boiler outlet is extracted by the induced draft fan of the boiler itself, and most of the soot impurities are removed through the treatment of the water film dust collector or the bag filter, and then enters the high-efficiency carbon absorption tower and the top-down milk of lime through the conveying pipeline. Ca 2+ Ions react to generate calcium carbonate solution with a pH value between 7.5 and 8.5, which is then transported to the circulation pool 1 for storage, then pumped to the small storage tank 2, and then sent to the filter juice reaction tank 3 or the filling tank 3.

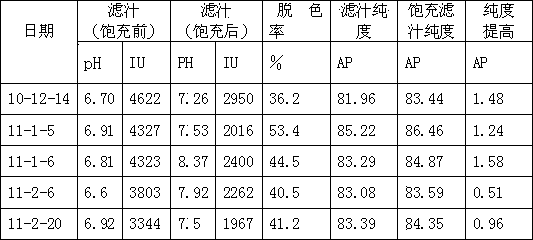

[0016] The filtered juice filtered from the vacuum suction filter without filter cloth is stored in the filtered juice storage tank 8. The filtered juice is turbid and dark in pigment, with a little floating mud. It is then transported by the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com