Engine energy-saving carbon-reduction efficiency improving assisting device

An auxiliary device and engine technology, applied in the charging system, adding non-fuel substances to the fuel, electrolysis process, etc., can solve the problems of high pollution components in exhaust gas, easy generation of black smoke, and inability to further reduce fuel consumption, etc., to achieve clean Effects of carbon deposition, horsepower enhancement, and combustion efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in more detail below in conjunction with the drawings, so as to have a further understanding of the technical means, functions and effects of the present invention.

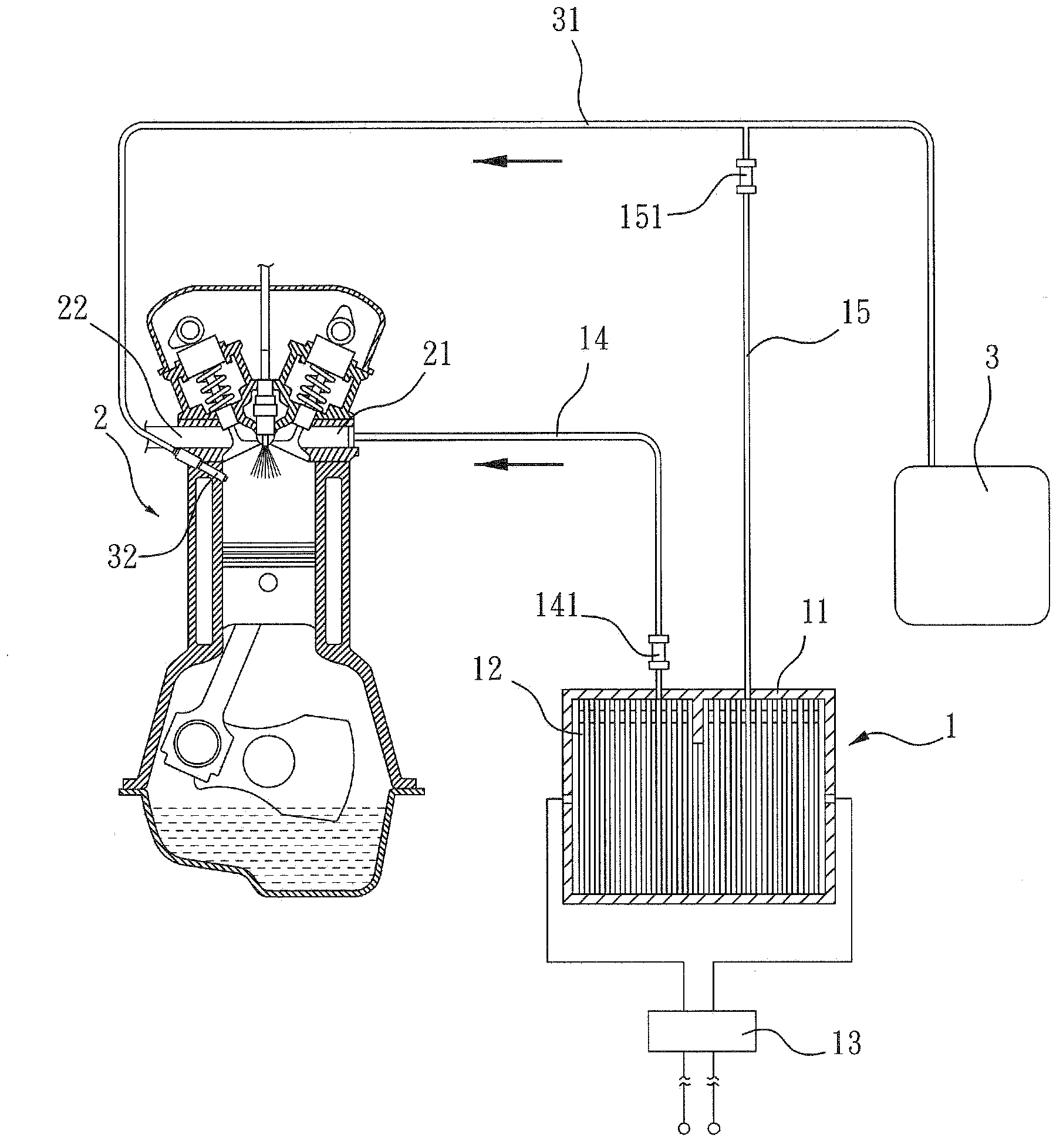

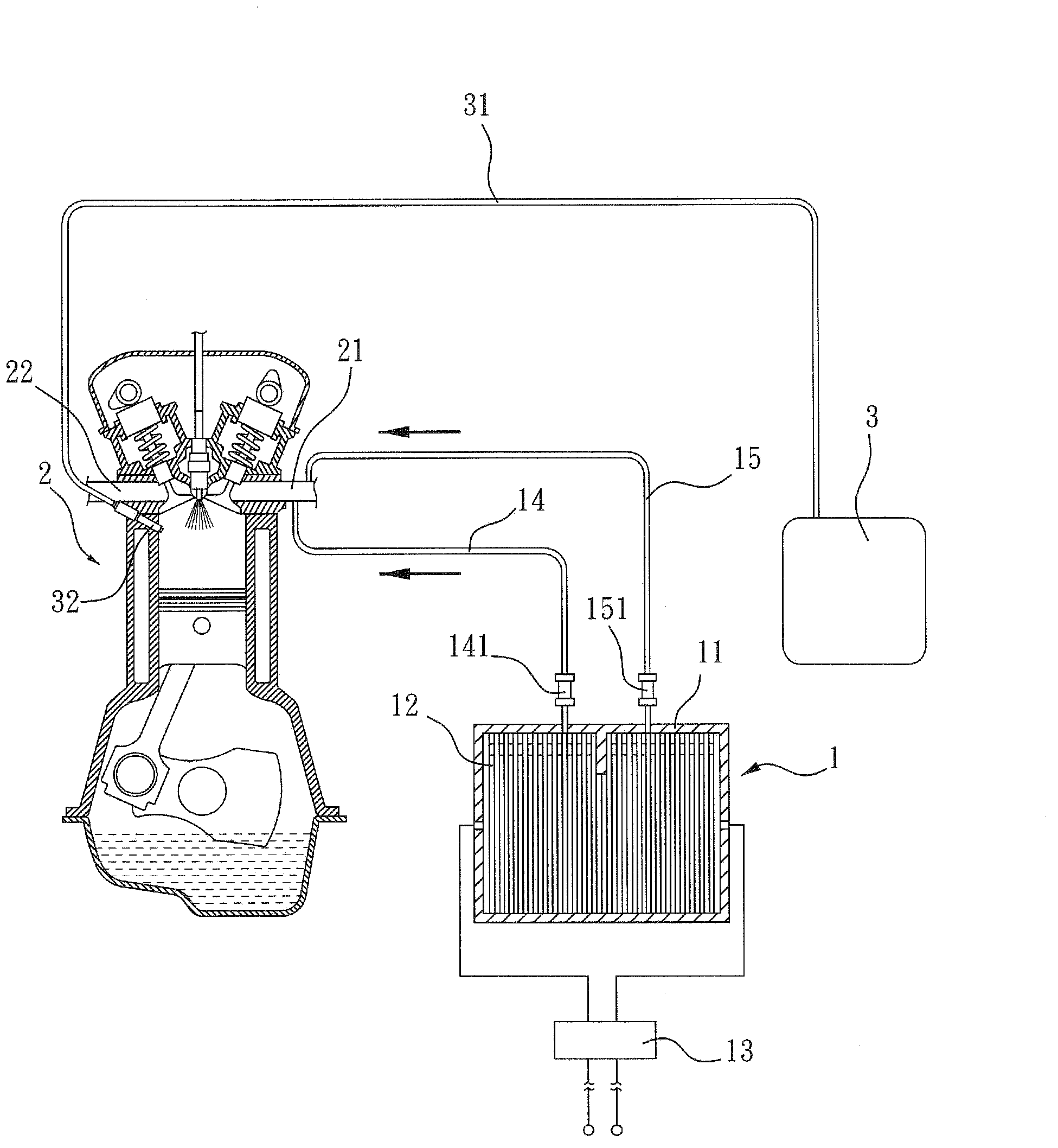

[0023] figure 1 It shows the schematic diagram of the first embodiment of the auxiliary device of the present invention applied to the automobile fuel supply system; it is characterized in that an electrolytic cell 1 is installed in an appropriate position of the automobile, and a plurality of chemical reactions are provided inside the cell body 11 of the electrolytic cell 1 to generate electrolysis plate 12, the electrolytic tank 1 is electrically connected to the battery equipped with the car through a transformer 13; the battery voltage of a general car is 12V (volts), and the voltage is reduced to 6V (volts) through the transformer 13 and then input into the electrolytic tank 1 to provide For electrolytic chemical reactions....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com