Method for preparing hollow carbon nano cage through burning

A hollow carbon and nano cage technology, applied in nano carbon, nano technology, nano technology and other directions, can solve problems such as unfriendly reagents, toxic environment, complex control, etc., and achieve the effects of low raw material price, simple equipment and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] All the reagents used in the process of preparing the hollow carbon nanocage of the present invention are environment-friendly reagents, the generated magnesium salt solution can be recycled, the equipment required for the whole process is simple, the raw material price is low, the process is environmentally friendly and pollution-free, and can be produced in large quantities. It is a new preparation method of carbon nanocage.

[0026] The hollow carbon nanocage prepared by the present invention may contain, in addition to carbon, magnesium, nitrogen, and / or other elements compatible with the aqueous solution, such as boron and / or sulfur.

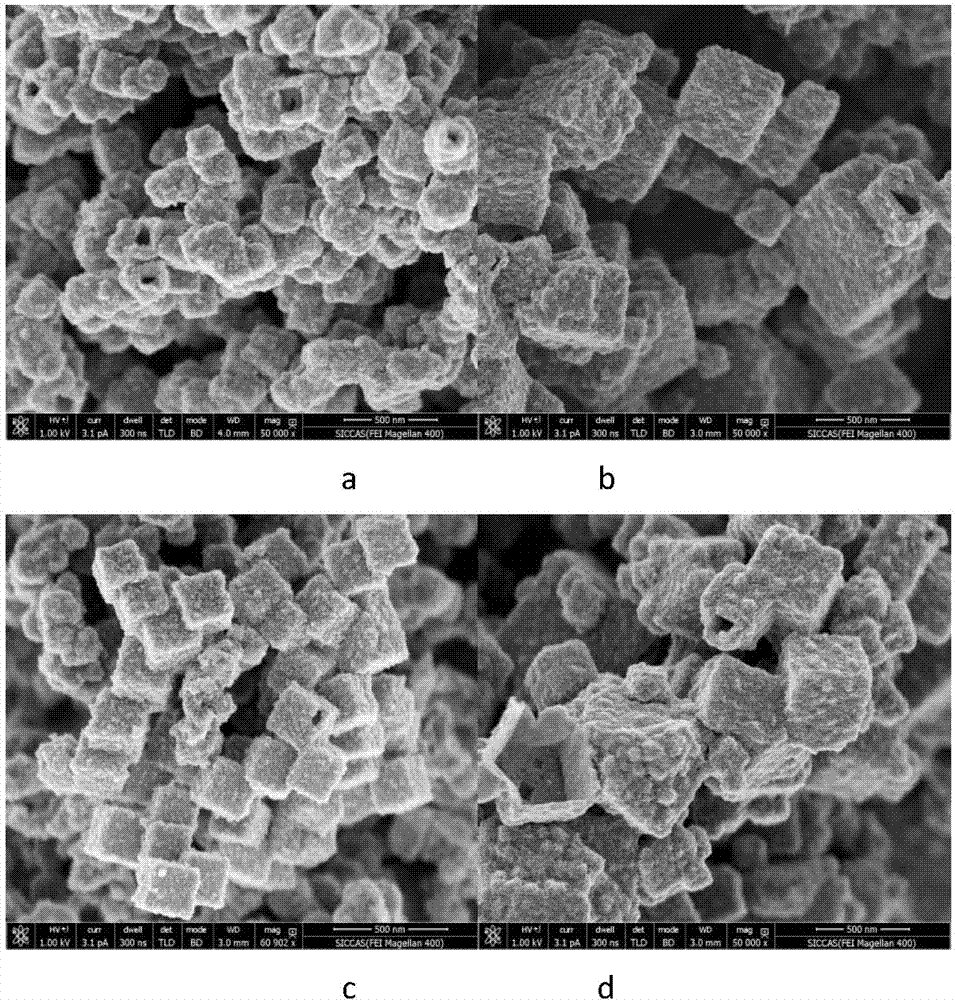

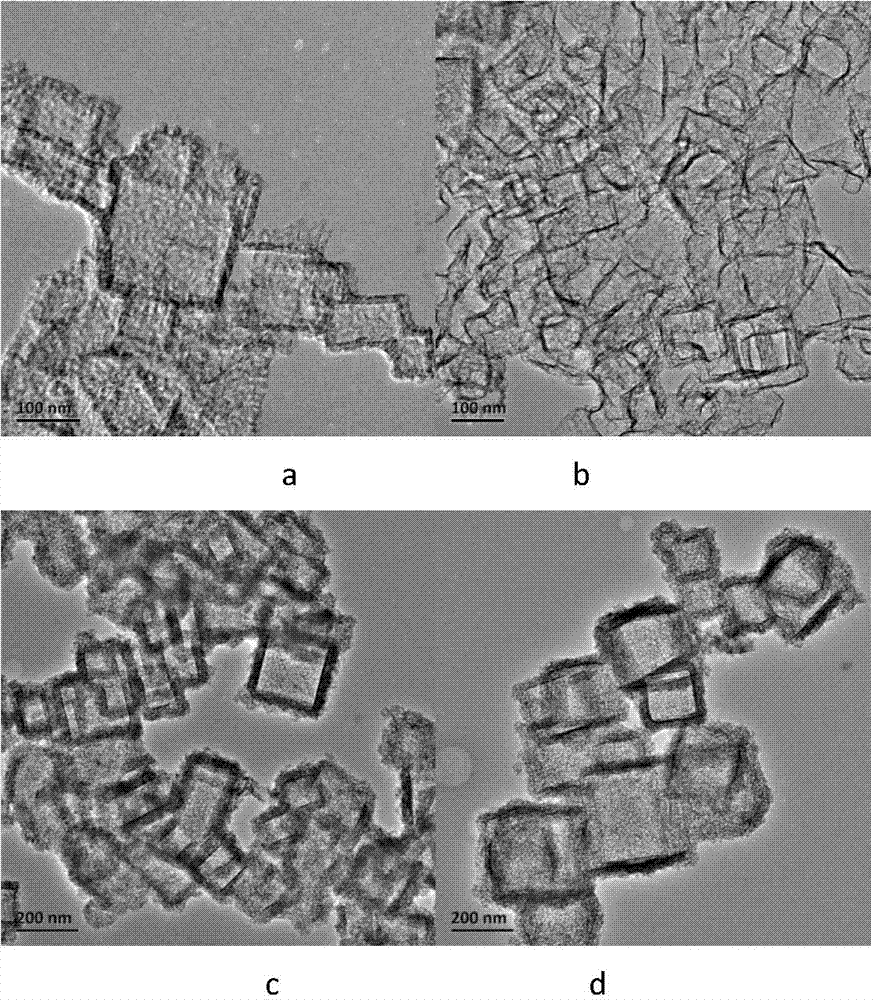

[0027] Moreover, the shell layer of the hollow carbon nanocage prepared by the present invention has a mesoporous structure and has the advantages of large specific surface area and the like. Its pore volume can be 0.5~1.5cm 3 g -1 , the specific surface area can be 200-500m 2 g -1 . figure 1 and figure 2 The SEM photos and TE...

Embodiment 1

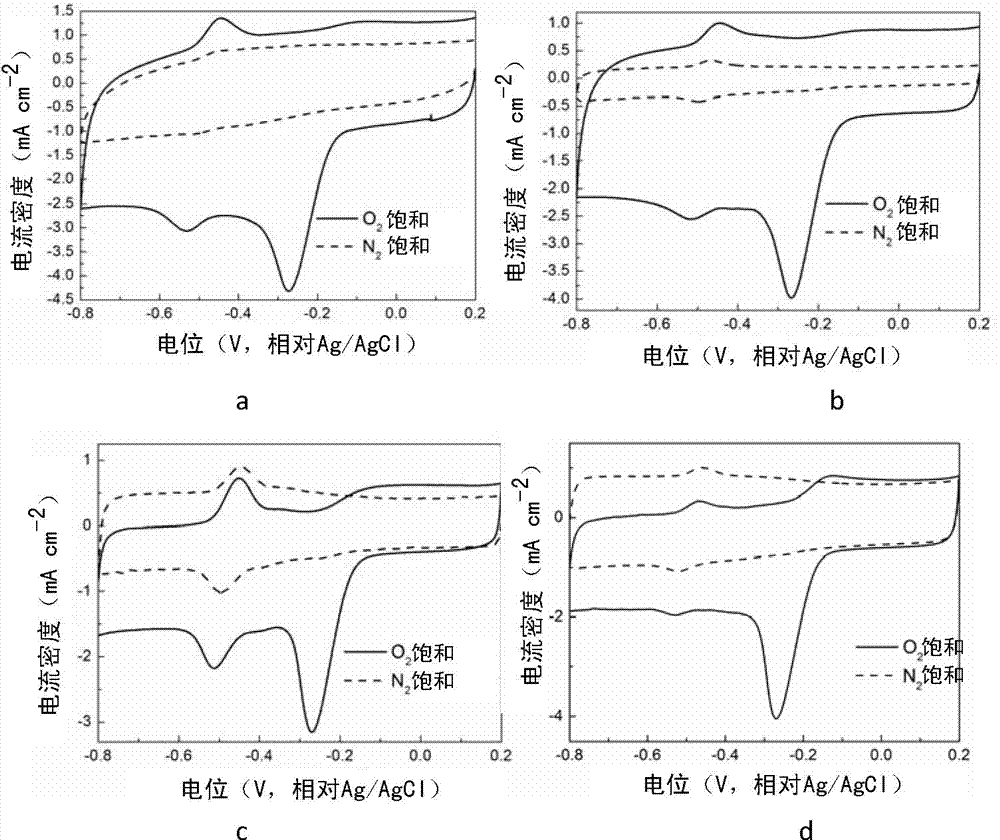

[0030] Add a small amount of water to a sealable container, filled with enough carbon dioxide. 5 grams of magnesium bars were ignited in air and quickly placed in the above container. After the magnesium strips are completely burned, the ash that falls into the water is collected by centrifugation. Put the obtained ash in a beaker, add 10ml of 0.5mol / L hydrochloric acid and stir it magnetically. After reacting for 24 hours, the black solid was centrifuged, washed and dried to obtain a hollow carbon nanocage doped with nitrogen, wherein the doping amount of nitrogen was 0.5 at.%. The aqueous solution of the magnesium salt containing excess hydrochloric acid can be recycled for another use. The prepared sample has good oxygen reduction performance, and its CV curve in oxygen / nitrogen saturated potassium hydroxide solution is as follows: image 3 Shown in Figure a. Its SEM photos and TEM photos are as follows figure 1 , 2 As shown in Figure a, it can be seen that it has a l...

Embodiment 2

[0032]Add 10 mL of boric acid aqueous solution into a sealable container, where the concentration of boric acid is 0.1 mol / L, filled with enough carbon dioxide. 5 grams of magnesium bars were ignited in air and quickly placed in the above container. After the magnesium strips are completely burned, the ash falling into the aqueous solution is collected by centrifugation. Put the obtained ash in a beaker, add 10ml of 0.5mol / L hydrochloric acid and stir it magnetically. After reacting for 24 hours, centrifuge the black solid therein, wash and dry to obtain a hollow carbon nanocage doped with nitrogen and boron elements, wherein the doping amount of nitrogen element is 0.3 at.%, and the doping amount of boron element is 0.3 at.%. is 0.8 at.%. The aqueous solution of the magnesium salt containing excess hydrochloric acid can be recycled for another use. The prepared sample has good oxygen reduction performance, and its CV curve in oxygen / nitrogen saturated potassium hydroxide s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com