Preparation method of graphene oxide dispersion liquid

A technology of graphene dispersion liquid and graphite, which is applied in the direction of chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of long time, low yield, difficulty of exfoliating into single-layer graphene, etc., to reduce production Cost and energy consumption, good dispersion and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

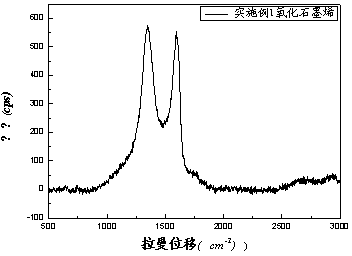

Embodiment 1

[0043] A preparation method for a graphene oxide dispersion, specifically comprising the following steps:

[0044] (1) Preparation of sulfate intercalated graphite / sulfuric acid mixture

[0045] At normal temperature, 1.5g of graphite and 30ml of concentrated sulfuric acid with a concentration of 98% were mixed in a ratio of 1g:20mL, and ultrasonicated for 1h to obtain a sulfate-intercalated graphite / sulfuric acid mixture;

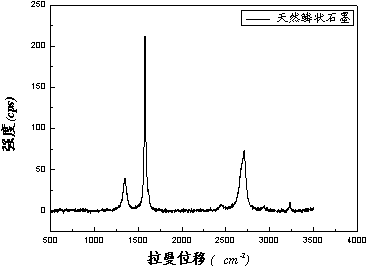

[0046] Described graphite is natural graphite powder;

[0047] (2), the preparation of preliminary graphite oxide:

[0048] Add 6g of potassium permanganate at one time to the sulfate intercalated graphite / sulfuric acid mixture obtained in step (1) at normal temperature, and ultrasonicate for 10s to obtain the sulfate intercalated graphite / sulfuric acid / potassium permanganate mixture;

[0049] The amount of potassium permanganate added is calculated according to the mass ratio, that is, graphite: potassium permanganate is 1:4;

[0050] Then the graphite...

Embodiment 2

[0063] A preparation method for a graphene oxide dispersion, specifically comprising the following steps:

[0064] (1) Preparation of sulfate intercalated graphite / sulfuric acid mixture

[0065] At normal temperature, 1.5g of graphite and 30ml of concentrated sulfuric acid with a concentration of 98% were mixed in a ratio of 1g:20mL, and ultrasonicated for 1h to obtain a sulfate-intercalated graphite / sulfuric acid mixture;

[0066] Described graphite is natural flake graphite;

[0067] (2), the preparation of preliminary graphite oxide:

[0068] Add 6g of potassium permanganate at one time to the sulfate intercalated graphite / sulfuric acid mixture obtained in step (1) at normal temperature, and ultrasonicate for 10s to obtain the sulfate intercalated graphite / sulfuric acid / potassium permanganate mixture;

[0069] The amount of potassium permanganate added is calculated according to the mass ratio, that is, graphite: potassium permanganate is 1:4;

[0070] The obtained graph...

Embodiment 3

[0089] A preparation method for a graphene oxide dispersion, specifically comprising the following steps:

[0090] (1) Preparation of sulfate intercalated graphite / sulfuric acid mixture

[0091] At normal temperature, 1.5g of graphite and 30ml of mass percent concentration of 98% concentrated sulfuric acid were mixed in the ratio of 1g:20mL, ultrasonic 1h, prepared graphite / sulfuric acid mixture for sulfate radical intercalation;

[0092] Described graphite is microcrystalline graphite;

[0093] (2), the preparation of preliminary graphite oxide:

[0094] Add 6g of potassium permanganate at one time to the sulfate intercalated graphite / sulfuric acid mixture obtained in step (1) at normal temperature, and ultrasonicate for 10s to obtain the sulfate intercalated graphite / sulfuric acid / potassium permanganate mixture;

[0095] The amount of potassium permanganate added is calculated according to the mass ratio, that is, graphite: potassium permanganate is 1:4;

[0096] Then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com