Method for synthesizing cyclohexenone through catalytic oxidation of cyclohexene

A technology of cyclohexenone and catalytic oxidation is applied in the field of synthesis of cyclohexenone by catalytic oxidation of cyclohexene, and the synthesis field of cyclohexenone achieves the effects of reducing energy consumption, low reaction temperature and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

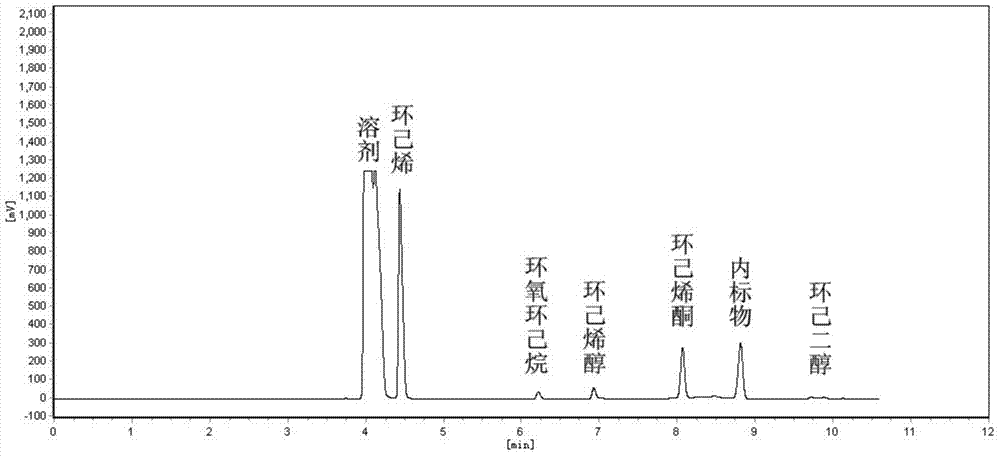

[0024] Add 8.1g of cyclohexene, acetonitrile, solid catalyst nitrogen-doped carbon nanotubes, and o-dichlorobenzene (internal standard) into a closed reaction kettle and mix to form a mixed suspension, which is then ultrasonically treated to form a suspension (frequency 40KHz, power 200W and time 15min). Among them, the volume ratio of acetonitrile to cyclohexene is 2:1, and the weight ratio of nitrogen-doped carbon nanotubes (3.96% nitrogen content, atomic content) as a catalyst to cyclohexene is 0.00617:1. The mixed suspension was heated to 80° C. with stirring, and oxygen was introduced. Oxygen is continuously replenished and kept at a constant pressure of 1.0 MPa through a pressure stabilizing device and a flow meter connected to an oxygen source during the reaction process because the oxygen is continuously consumed in a stoichiometric ratio. After reacting for 4 hours, discharge the liquid-solid phase mixture from the bottom of the reactor, and filter it to obtain a sol...

Embodiment 2~5

[0026] Add 8.1g of cyclohexene, acetonitrile, solid catalyst nitrogen-doped carbon nanometer, and o-dichlorobenzene (internal standard) into a closed reaction kettle and mix to form a mixed suspension, which is then ultrasonically treated to form a suspension (frequency of 40KHz, power 200W and time 15min). Wherein, the volume ratio of acetonitrile to cyclohexene is 2:1, and the weight ratio of nitrogen-doped carbon nanotubes as catalyst to cyclohexene is 0.00617:1. The mixed suspension was heated to the temperature shown in Table 1 respectively under stirring, and oxygen gas was introduced. Oxygen is continuously replenished and kept at a constant pressure of 1.0 MPa through a pressure stabilizing device and a flow meter connected to an oxygen source during the reaction process because the oxygen is continuously consumed in a stoichiometric ratio. After reacting for 4h, the liquid mixture was analyzed to measure the conversion rate of cyclohexene and the selectivity of cyclo...

Embodiment 6~9

[0030]Add 8.1g of cyclohexene, acetonitrile, solid catalyst nitrogen-doped carbon nanotubes, and o-dichlorobenzene (internal standard) into a closed reaction kettle and mix to form a mixed suspension, which is then ultrasonically treated to form a suspension (frequency 40KHz, power 200W and time 15min). Wherein, the volume ratio of acetonitrile to cyclohexene is 2:1, and the weight ratio of nitrogen-doped carbon nanotubes as catalyst to cyclohexene is 0.00617:1. The mixed suspension was heated to 80° C. under stirring, and oxygen gas was introduced. Because the reaction process constantly consumes oxygen in a stoichiometric ratio, oxygen is constantly replenished and kept constant at 1.0 MPa by a pressure stabilizing device and a flow meter connected to an oxygen source during the reaction, and the reaction is performed at the time shown in Table 2. The results of the conversion of cyclohexene and the selectivity of cyclohexenone are shown in Table 2. Analysis of the data in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com