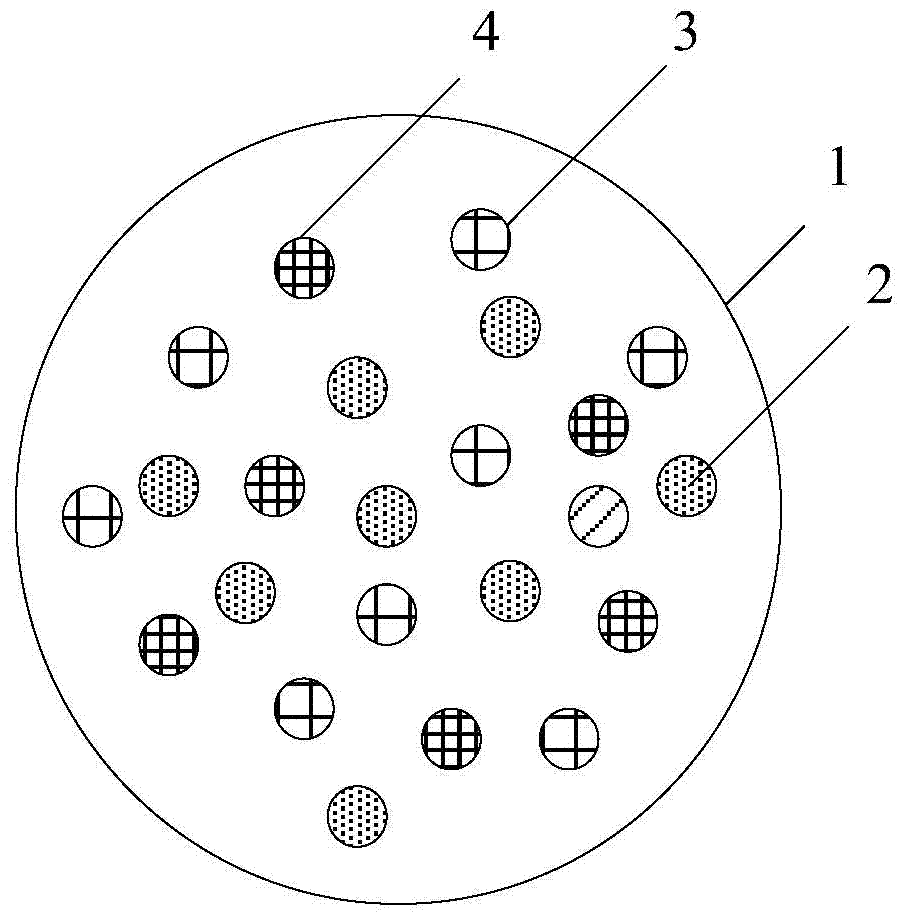

White quantum dot composite particle as well as preparation method and device thereof

A technology of composite particles and red light quantum dots, which is applied in the field of preparation devices, white light quantum dot composite particles and preparation methods thereof, can solve the problems of poor stability of quantum dot materials, low quantum efficiency and the like, and achieves high quantum efficiency, simple preparation method, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

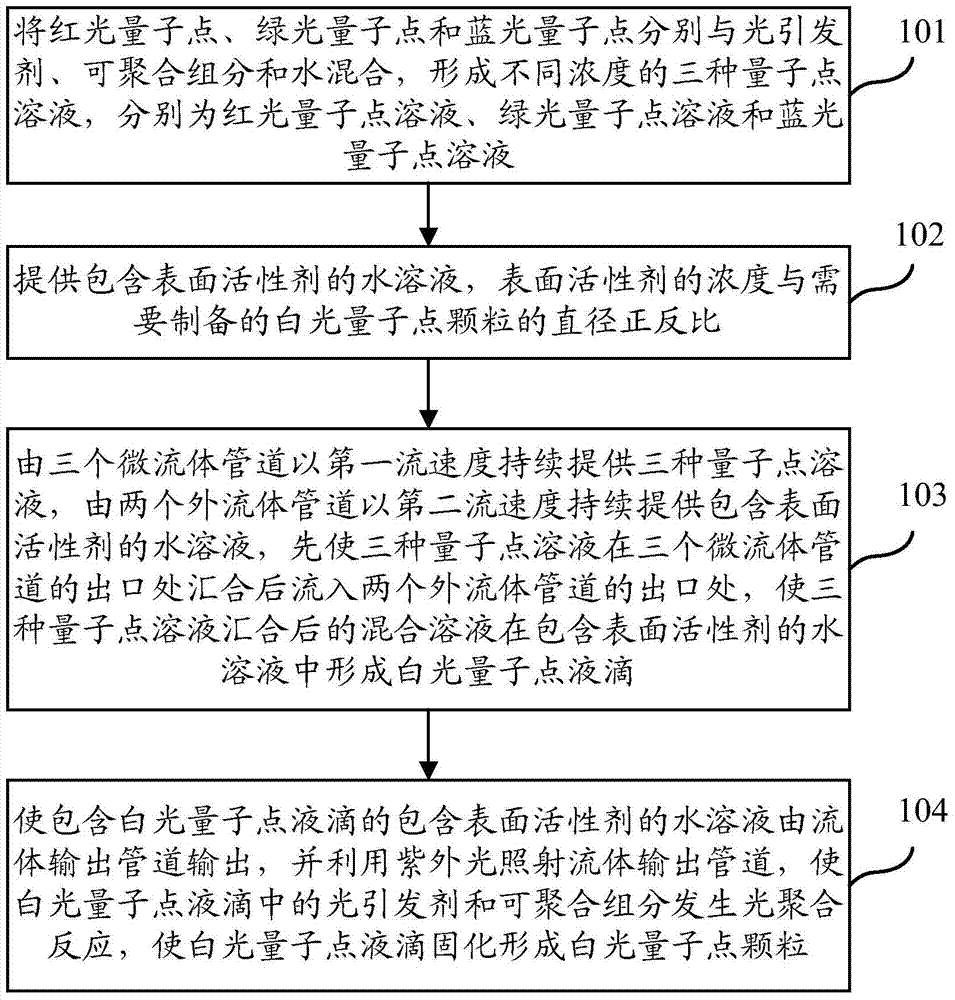

[0057] see figure 2 , the embodiment of the present invention provides a preparation method of white light quantum dot composite particles, including:

[0058] 101. Mix red light quantum dots, green light quantum dots and blue light quantum dots with photoinitiators, polymerizable components and water respectively to form three kinds of quantum dot solutions with different concentrations, which are red light quantum dot solutions, green light quantum dot solutions and Blue light quantum dot solution.

[0059] 102. Provide an aqueous solution containing a surfactant, and the concentration of the surfactant is directly and negatively proportional to the diameter of the white light quantum dot composite particles to be prepared.

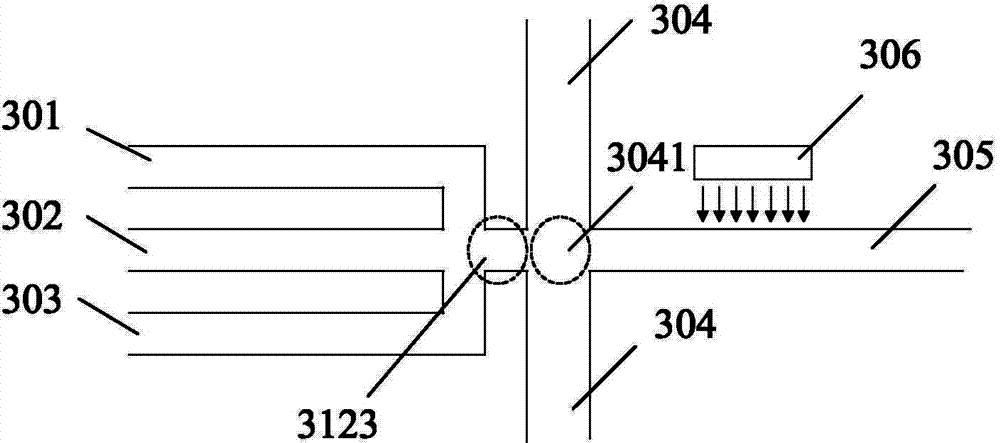

[0060] 103. The three microfluidic pipelines continuously provide three kinds of quantum dot solutions at the first flow rate, and the two external fluid pipelines continuously provide the aqueous solution containing surfactant at the second flow rate...

specific Embodiment 1

[0071]Step 1. Provide three primary color quantum dot solutions, for example: red light quantum dot solution, the mass percentage of red light quantum dots is 1%, the mass percentage of monomer methacryloylpropyl dimethyl chlorosilane is 91%, and the photoinitiator 1- The mass percentage of hydroxycyclohexyl phenyl ketone is 8%. Green light quantum dot solution, the mass percentage of green light quantum dots is 3%, the mass percentage of monomer methacryloylpropyl dimethyl chlorosilane is 90%, and the mass percentage of photoinitiator 1-hydroxycyclohexyl phenyl ketone is 7% . Blue light quantum dot solution, the mass percentage of blue light quantum dots is 15%, the mass percentage of monomer methacryloylpropyl dimethyl chlorosilane is 79%, and the mass percentage of photoinitiator 1-hydroxycyclohexyl phenyl ketone is 6% .

[0072] Step 2, providing an aqueous solution containing a surfactant, for example: the mass percentage of the surfactant sodium dodecylsulfonate (SDS) ...

specific Embodiment 2

[0075] Step 1. Provide three primary color quantum dot solutions, for example: red light quantum dot solution, the mass percentage of red light quantum dots is 1%, the mass percentage of monomer methacryloylpropyl dimethyl chlorosilane is 91%, and the photoinitiator 1- The mass percentage of hydroxycyclohexyl phenyl ketone is 8%. Green light quantum dot solution, the mass percentage of green light quantum dots is 3%, the mass percentage of monomer methacryloylpropyl dimethyl chlorosilane is 90%, and the mass percentage of photoinitiator 1-hydroxycyclohexyl phenyl ketone is 7% . Blue light quantum dot solution, the mass percentage of blue light quantum dots is 15%, the mass percentage of monomer methacryloylpropyl dimethyl chlorosilane is 79%, and the mass percentage of photoinitiator 1-hydroxycyclohexyl phenyl ketone is 6% .

[0076] Step 2, providing an aqueous solution containing a surfactant, for example: the mass percentage of the surfactant sodium dodecylsulfonate (SDS)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com