Low-smoke low-halogen flame-retardant insulation-grade PVC (polyvinyl chloride) sheath material for ultrahigh-voltage cable, and preparation of low-smoke low-halogen flame-retardant insulation-grade PVC sheath material

A technology of ultra-high voltage and sheathing materials, applied in the direction of insulated conductors, insulated cables, cables, etc., can solve the problems of non-rat proof, termite proof, low volume resistance, etc., and achieve the effect of excellent electrical performance and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

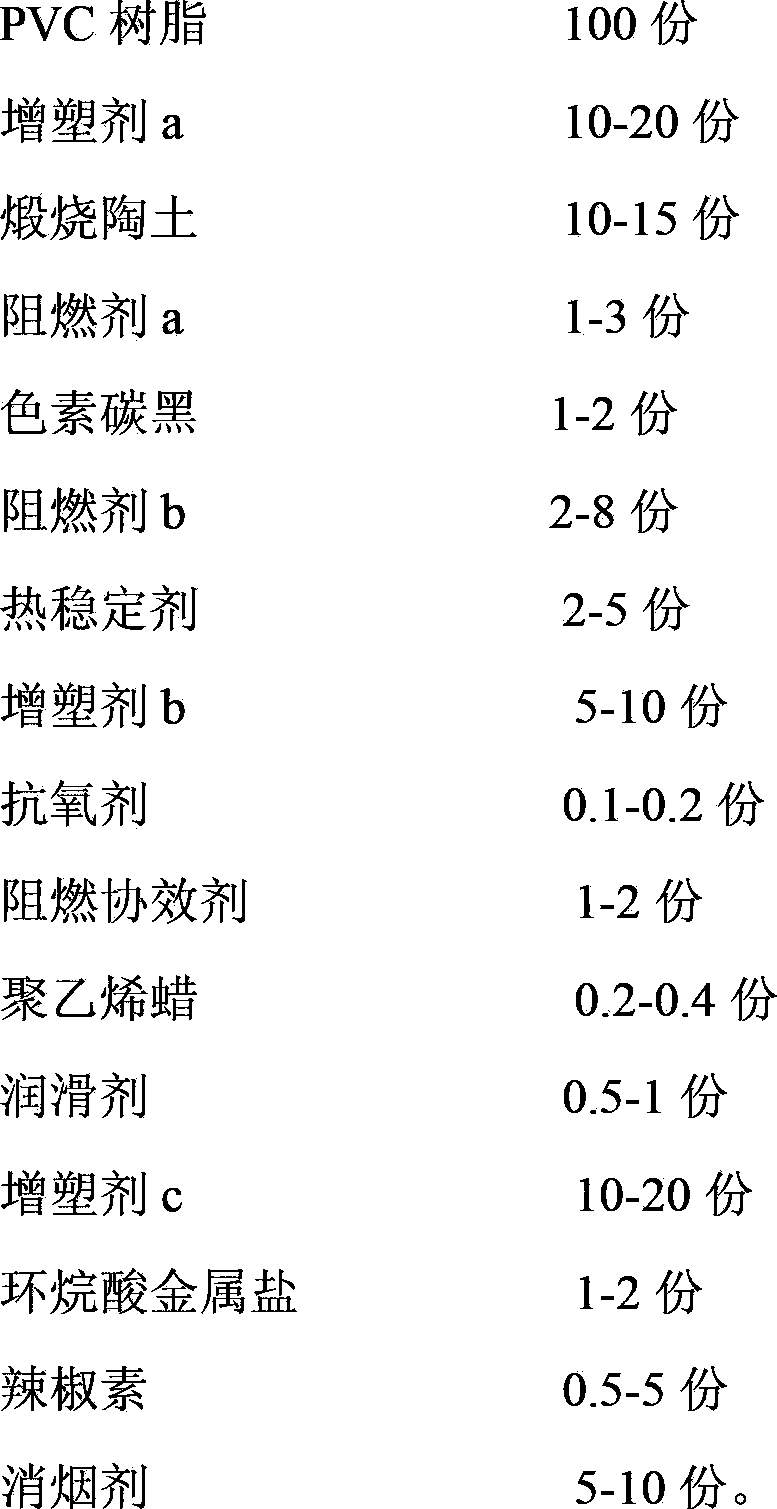

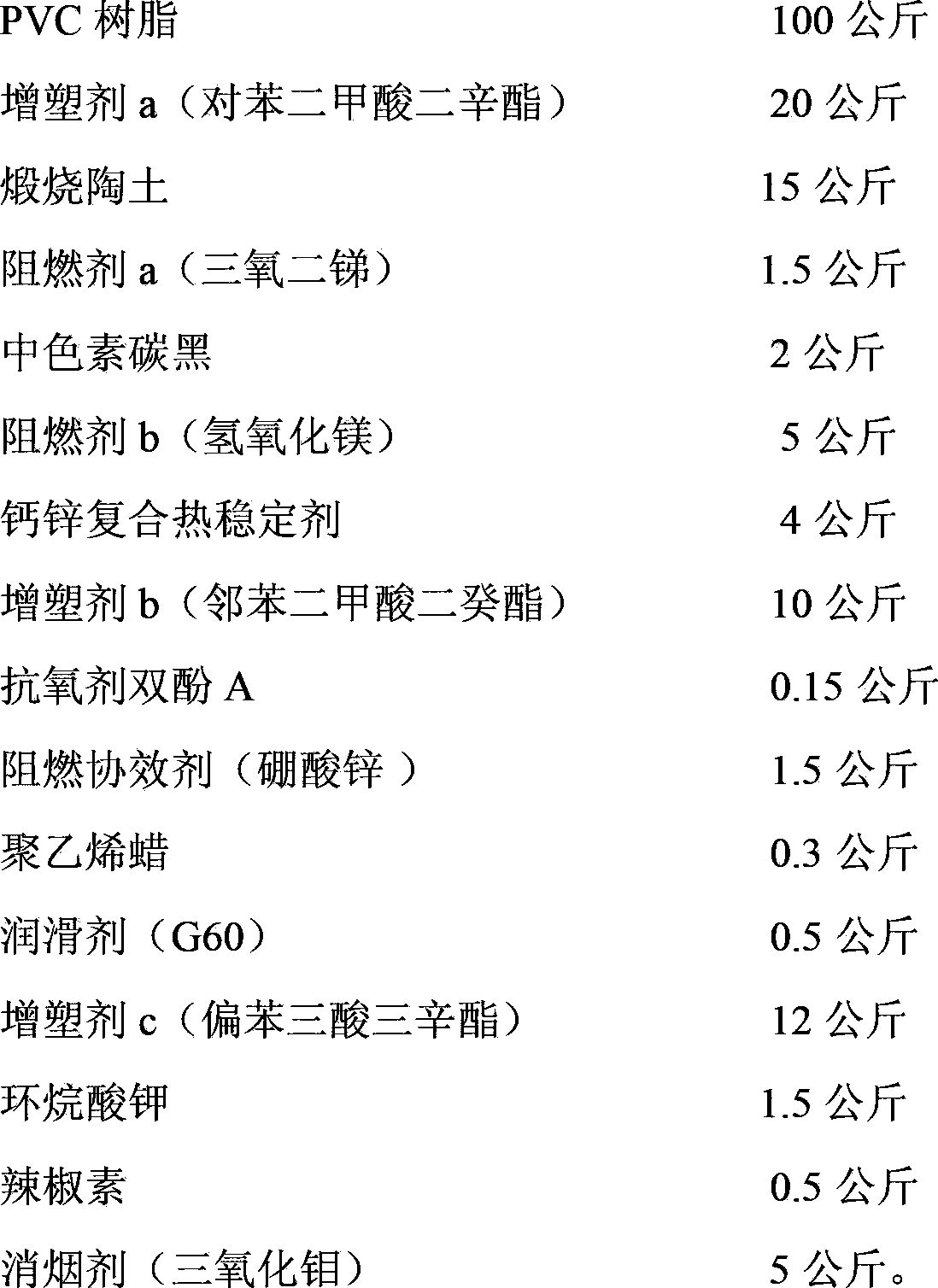

[0027] 1. Experimental materials

[0028]

[0029] 2. Preparation method

[0030] The method for preparing low-smoke, low-halogen, flame-retardant insulating grade PVC sheath material for extra-high voltage cables using the above-mentioned raw materials is as follows:

[0031] a. 20 kg of plasticizer a dioctyl terephthalate, 1.5 kg of flame retardant a antimony trioxide, 5 kg of flame retardant b magnesium hydroxide, 0.15 kg of antioxidant, and flame retardant synergist boric acid 1.5 kilograms of zinc and 5 kilograms of molybdenum trioxide are put into a three-roll mill and ground into a slurry of a certain fineness;

[0032] b. Mix the ground slurry with 100 kg of PVC resin, 15 kg of calcined clay, 2 kg of medium pigment carbon black, 4 kg of composite environmental-friendly heat stabilizer, 10 kg of plasticizer b, and 0.3 kg of polyethylene wax for efficient lubrication 0.5 kg of agent G60, 12 kg of plasticizer c trioctyl trimellitate, 1.5 kg of potassium naphthenate, ...

Embodiment 2

[0036] 1. Experimental materials:

[0037]

[0038] 2. Preparation method:

[0039] Using the above raw materials, the preparation method of the low-smoke, low-halogen, flame-retardant insulating grade PVC sheath material for extra-high voltage cables is the same as that in Example 1.

Embodiment 3

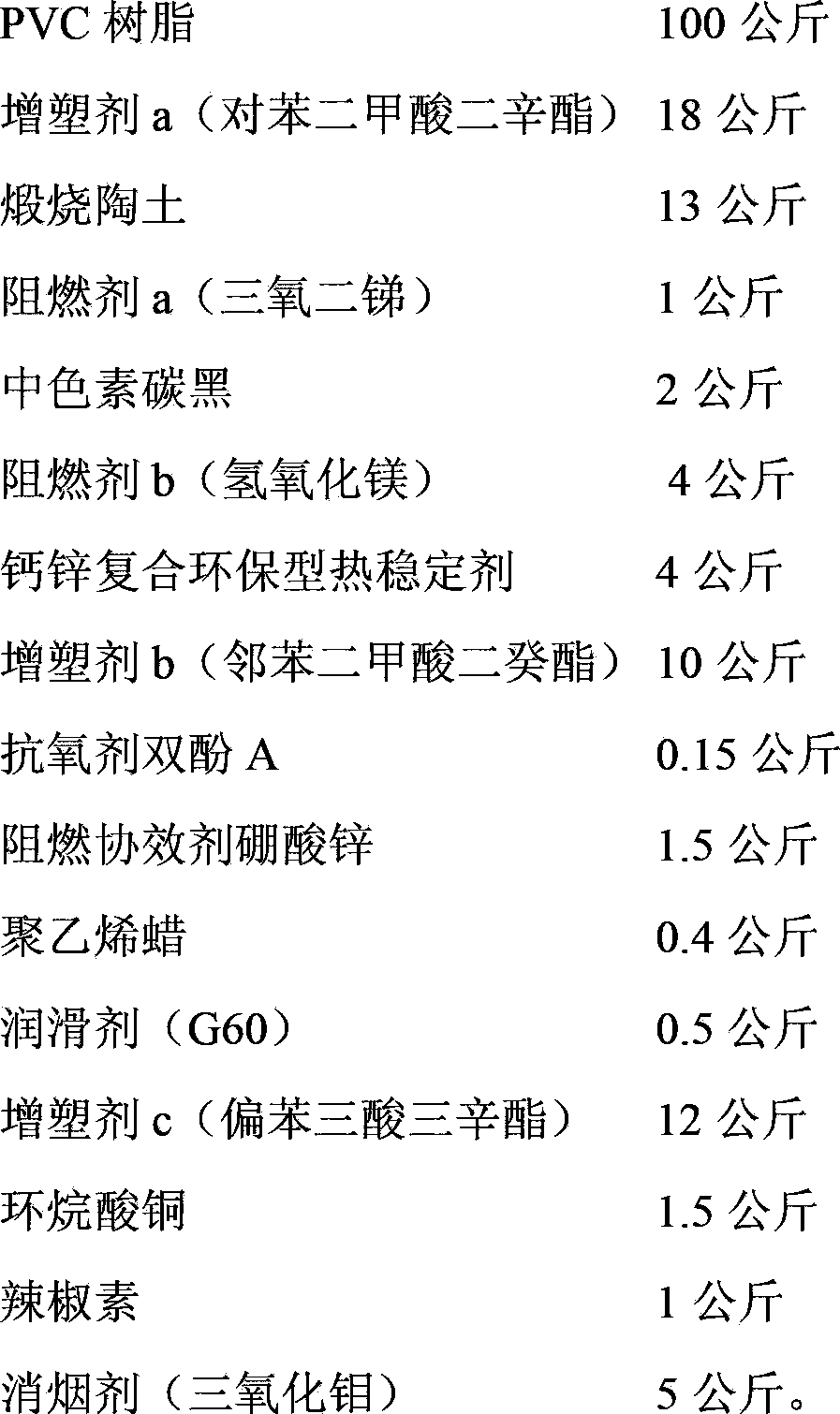

[0041] 1. Experimental materials:

[0042]

[0043]

[0044] 2. Preparation method:

[0045] Using the above raw materials, the preparation method of the low-smoke, low-halogen, flame-retardant insulating grade PVC sheath material for extra-high voltage cables is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com