Composite oxide coated mica pearled composite pigment and preparation method thereof

A technology of composite oxides and composite pigments, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., to achieve the effect of rich variety, easy reaction, and soft pearl luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

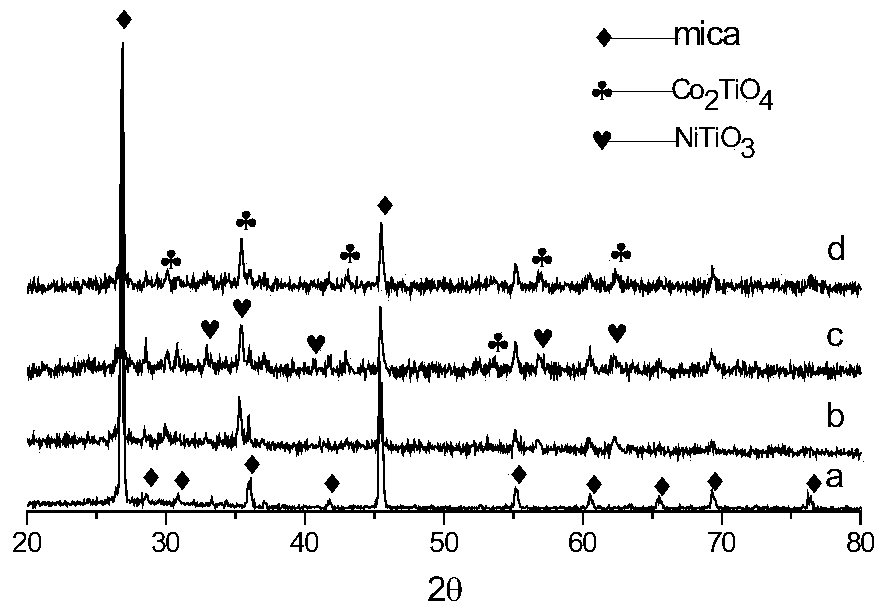

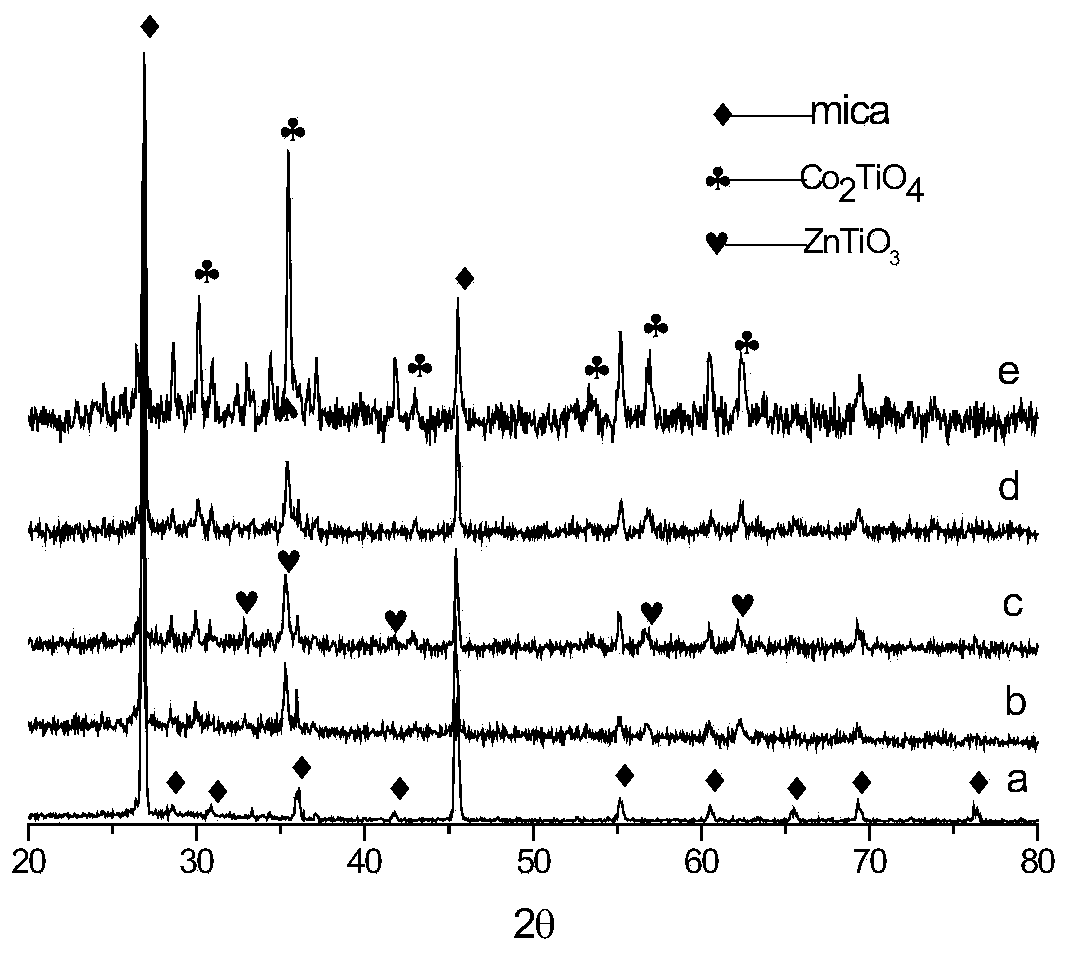

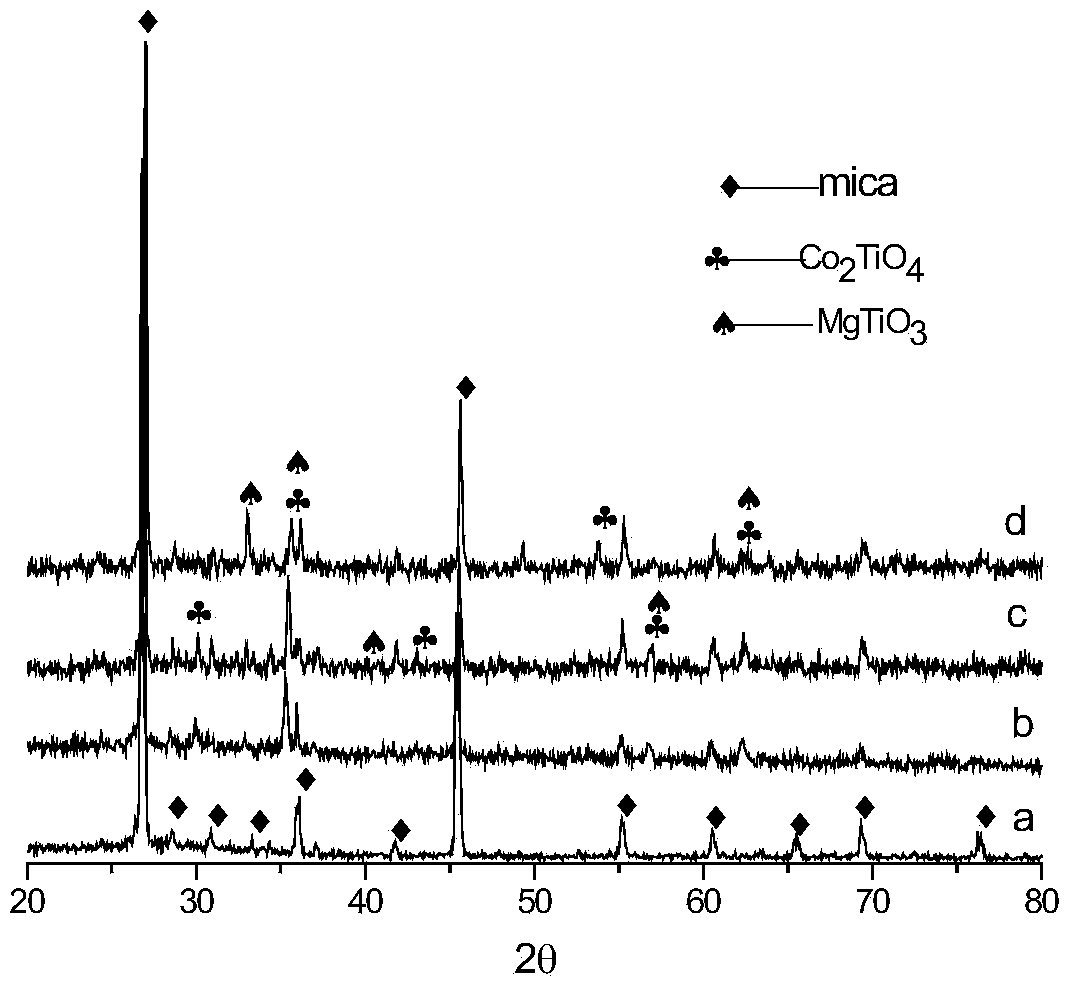

Image

Examples

Embodiment 1

[0030] (1) Mica pretreatment: 70-80°C water bath temperature, 3% hydrochloric acid to mica liquid-solid ratio of 20, stirring and cleaning for 30 minutes, washing and drying. Take 30g of pretreated mica (particle size 5-25μm) to prepare 10wt% mica slurry, and adjust the pH to 2.

[0031] (2) Co. 2-x Ni x TiO 4 / Mica (x=0.3) composite pigment precursor preparation: preparation of titanium, cobalt, nickel ion mixed solution: 8.5gTiCl 4 , was added dropwise to a solution of 20ml concentrated hydrochloric acid and 50ml deionized water, and Co(NO 3 ) 2 .6H 2 O21.72g, Ni (NO 3 ) 2 .6H 2 O3.83g and surplus 150ml deionized water; 25g sodium hydroxide is dissolved in water and is mixed with the solution of the same volume as titanium cobalt nickel ion solution. Heat the mica slurry in a water bath to 80°C under the condition of mechanical stirring at 200rmp, slowly add titanium cobalt nickel solution and sodium hydroxide solution dropwise at the same time, dropwise time is 2h...

Embodiment 2

[0034] (1) Mica pretreatment: 70-80°C water bath temperature, 5% hydrochloric acid to mica liquid-solid ratio of 20, stirring and cleaning for 30 minutes, washing and drying. Take 30g of pretreated mica (particle size 5-25μm) to prepare 10wt% mica slurry, and adjust the pH to 2.

[0035] (2) Co. 2-x Ni x TiO 4 / Mica (x=0.5) composite pigment precursor preparation: preparation of titanium cobalt nickel ion mixed solution: 8.5gTiCl 4 , was added dropwise to a solution of 20ml of concentrated hydrochloric acid and 50ml of deionized water, and 19.16g of Co (NO 3 ) 2 .6H 2 O, 6.38gNi (NO 3 ) 2 .6H 2 O and surplus 150ml deionized water; 25.5g sodium hydroxide is dissolved in water and is mixed with the solution of the same volume as titanium cobalt nickel ion solution. Heat the mica slurry in a water bath to 80°C under the condition of mechanical stirring at 200rmp, slowly add titanium cobalt nickel solution and sodium hydroxide solution dropwise at the same time, dropwise...

Embodiment 3

[0039] (1) Mica pretreatment: 70-80°C water bath temperature, 5% hydrochloric acid to mica liquid-solid ratio of 20, stirring and cleaning for 30 minutes, washing and drying. Take 30g of pretreated mica (particle size 5-25μm) to prepare 10wt% mica slurry, and adjust the pH to 2.

[0040] (2) Co. 2-x Ni x TiO 4 / Mica (x=0.5) composite pigment precursor preparation: preparation of titanium-cobalt-nickel ion mixed solution: 2.83gTiCl 4 , was added dropwise to a solution of 7ml of concentrated hydrochloric acid and 17ml of deionized water, and 6.38g of Co (NO 3 ) 2 .6H 2 O, 2.12gNi (NO 3 ) 2 .6H 2 O and surplus 50ml deionized water; 8.6g sodium hydroxide is dissolved in water and is mixed with the solution of the same volume as titanium cobalt nickel ion solution. Heat the mica slurry in a water bath to 80°C under the condition of mechanical stirring at 250rmp, slowly add titanium cobalt nickel solution and sodium hydroxide solution dropwise at the same time, dropwise tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com