Antistatic coating for ultraviolet curing and preparation method thereof

An antistatic and coating technology, applied in conductive coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as pollution, uneconomical, and volatile, and achieve good adhesion, long-lasting antistatic effect, and volatile The effect of low organic solvent content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

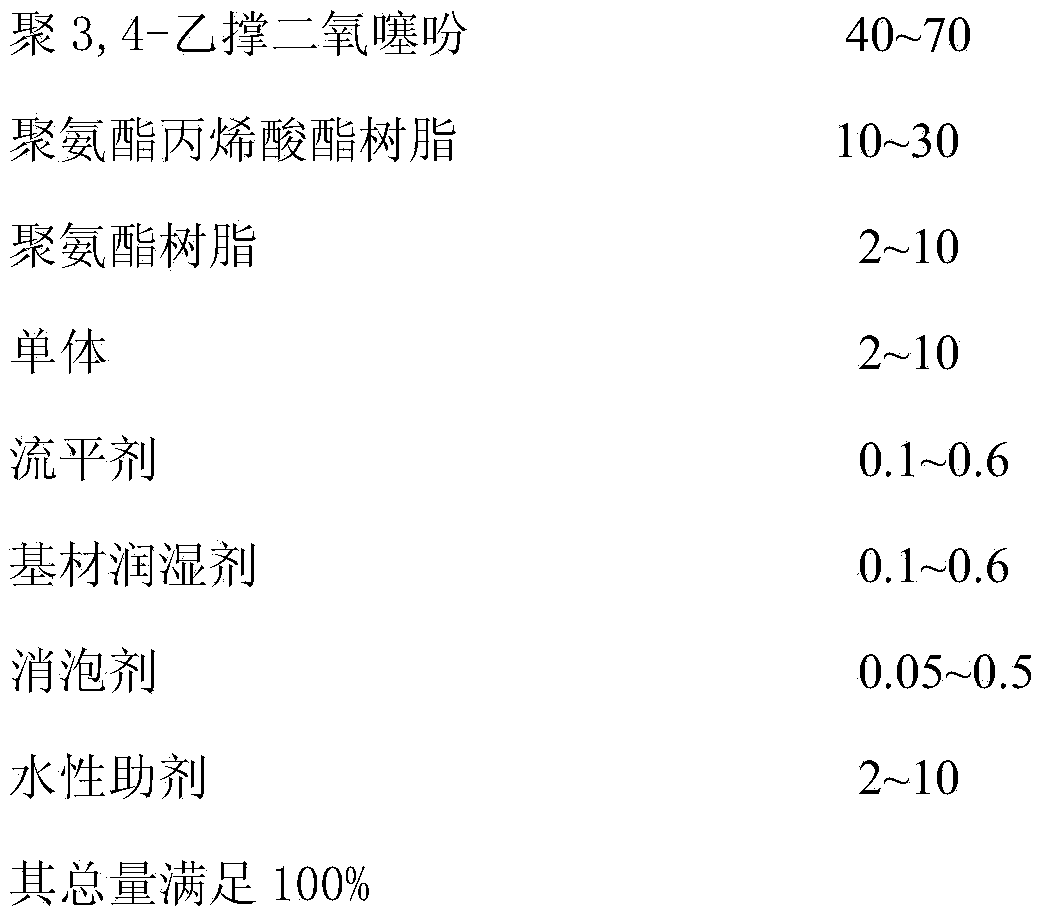

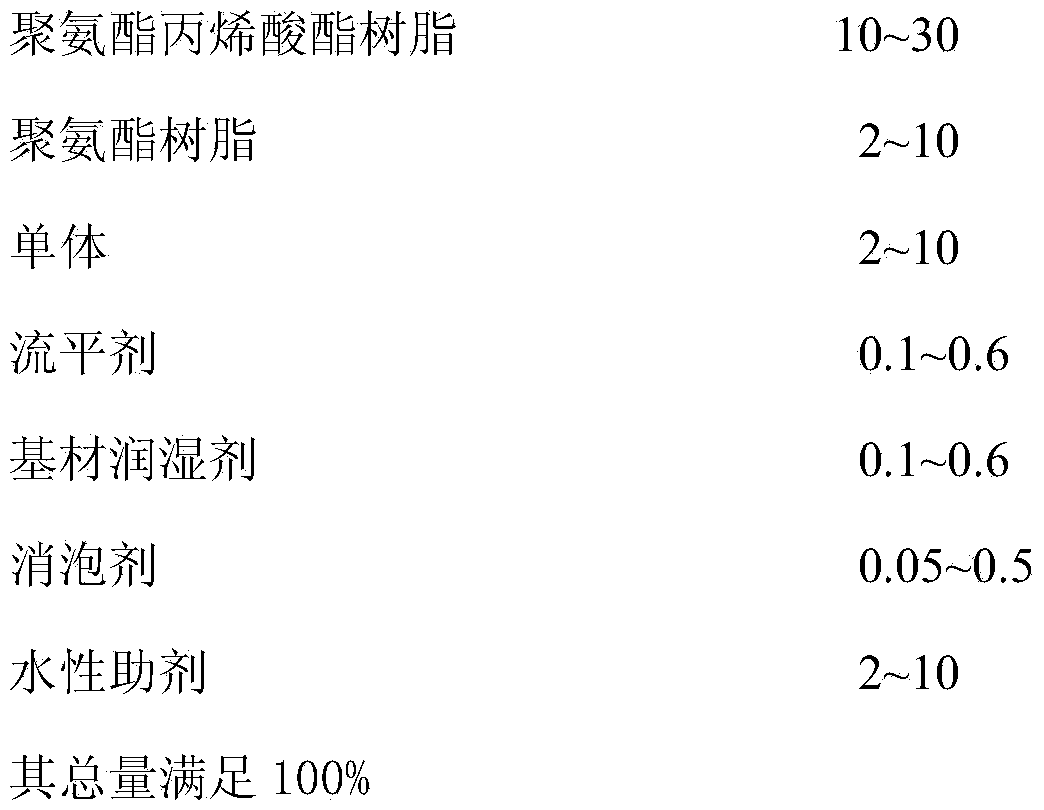

Method used

Image

Examples

Embodiment 1

[0026] Accurately weigh 15 parts of 3,4-ethylenedioxythiophene, 120 parts of sodium polystyrene sulfonate, 200 parts of sodium persulfate and 1 part of iron sulfate, add 2000 parts of deionized water, and adopt the method of solution polymerization, at room temperature to After reacting at 1000 rpm for 24 hours, add 200 parts each of anion exchange resin and cation exchange resin, reduce the speed to 600 rpm and react for another 3 hours to obtain a dark blue poly-3,4-ethylenedioxythiophene aqueous solution.

[0027] Accurately weigh 60% poly-3,4-ethylenedioxythiophene aqueous solution, 20% polyurethane acrylate resin, 5% polyurethane resin, 3% EM2386, 6% Irgacure184, 0.5% BYK333, 0.3% Tego500, 0.2% BYK024, 5 % propylene glycol methyl ether, join in the beaker, stir 30min under normal temperature, make described antistatic coating.

[0028] Coat the above mixed solution on the PET film with a 20 μm wire bar, send it into an oven to dry for 10 minutes, and then cure it on a UV ...

Embodiment 2

[0030] Accurately weigh 10 parts of 3,4-ethylenedioxythiophene, 100 parts of sodium polystyrene sulfonate, 180 parts of sodium persulfate and 1 part of ferric sulfate, add 2000 parts of deionized water, and adopt the method of solution polymerization at room temperature to 1000r p m After reacting for 24 hours, add 200 parts each of anion and cation exchange resins, reduce the speed to 600rpm and react for another 3 hours to obtain a dark blue poly-3,4-ethylenedioxythiophene aqueous solution.

[0031] Accurately weigh 50% poly-3,4-ethylenedioxythiophene aqueous solution, 23% polyurethane acrylate resin, 10% polyurethane resin, 6% EM2411, 4% Darocur1173, 0.4% BYK348, 0.3% Tego270, 0.3% BYK028, 6 % isopropanol, join in the beaker, stir 30min under normal temperature, make described antistatic coating.

[0032] Coat the above mixed solution on the PET film with a 15 μm wire bar, send it into an oven to dry for 10 minutes, and then cure it on a UV curing machine at a speed of 25 ...

Embodiment 3

[0034] Accurately weigh 8 parts of 3,4-ethylenedioxythiophene, 80 parts of sodium polystyrene sulfonate, 160 parts of sodium persulfate and 1 part of iron sulfate, add 2000 parts of deionized water, and adopt the method of solution polymerization at room temperature to After reacting at 1000 rpm for 24 hours, add 200 parts each of anion exchange resin and cation exchange resin, reduce the speed to 600 rpm and react for another 3 hours to obtain a dark blue poly-3,4-ethylenedioxythiophene aqueous solution.

[0035] Accurately weigh 40% poly-3,4-ethylenedioxythiophene aqueous solution, 30% polyurethane acrylate resin, 10% polyurethane resin, 8% EM226, 4% Irgacure184, 0.5% BYK358N, 0.3% Tego270, 0.2% BYK022, 7 % propylene glycol methyl ether, join in the beaker, stir 30min under normal temperature, make described antistatic coating.

[0036] Coat the above mixed solution on the PET film with a 15 μm wire bar, send it into an oven to dry for 10 minutes, and then cure it on a UV cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com