Hydrogen peroxide non-enzyme electrochemical sensor and preparation method thereof

A hydrogen peroxide, electrochemical technology, applied in the field of chemical sensors, can solve the problems of easy aggregation, difficult removal, catalyst reduction, etc., to improve the effective catalytic area and stability, sensitive detection and stability, make up for easy aggregation and shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

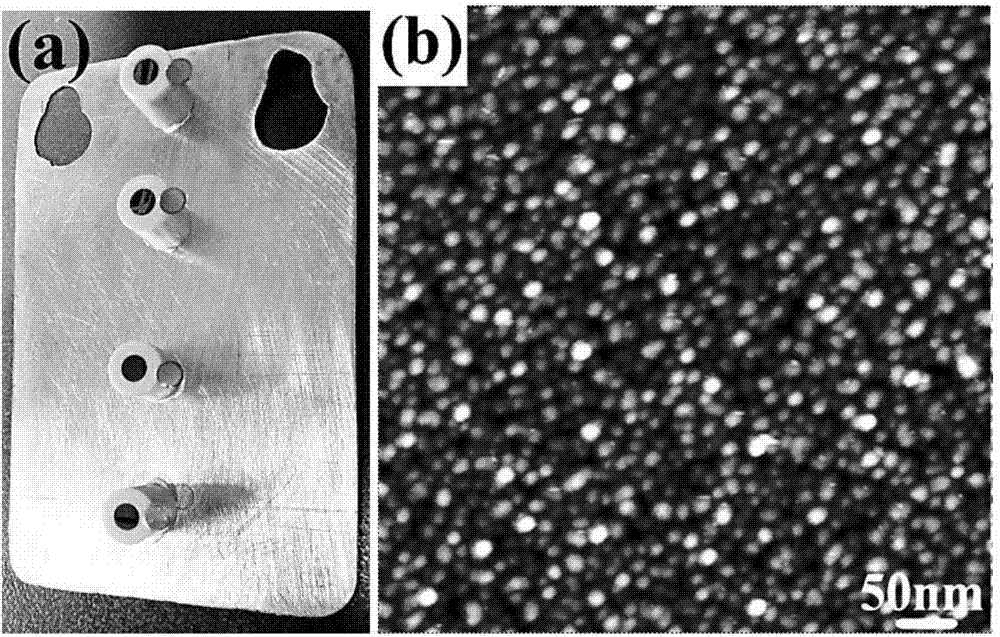

[0031] The embodiment of the present invention is introduced by taking the glassy carbon electrode modified by Ag nanoparticles as an example.

[0032] 1) Pretreatment and activation of glassy carbon electrodes. Use fine metallographic sandpaper and 0.3-0.05μm alumina powder to polish step by step, and polish it to the mirror surface. After washing away the surface dirt, move it into an ultrasonic water bath for cleaning for 2-3 minutes. Then put the electrode into 0.5molL -1 h 2 SO 4 The solution is activated by cyclic voltammetry, and the peak potential difference in the cyclic voltammogram obtained under laboratory conditions is below 80mV, and as close as possible to 64mV, the electrode can be used.

[0033] 2) Using nanoparticle beam source. Vacuum the system to 1×10 -3 When Pa or above, a variety of buffer gases are used and magnetron sputtering is performed, and the principle of differential vacuum is used to form a beam of Ag nanoparticles flying in the air 3) Lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com