Catalyst for reaction of preparing aviation kerosene by castor oil and a preparation method of catalyst

A technology for aviation kerosene and catalyst, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of improving liquid yield, prolonging life, and reducing particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

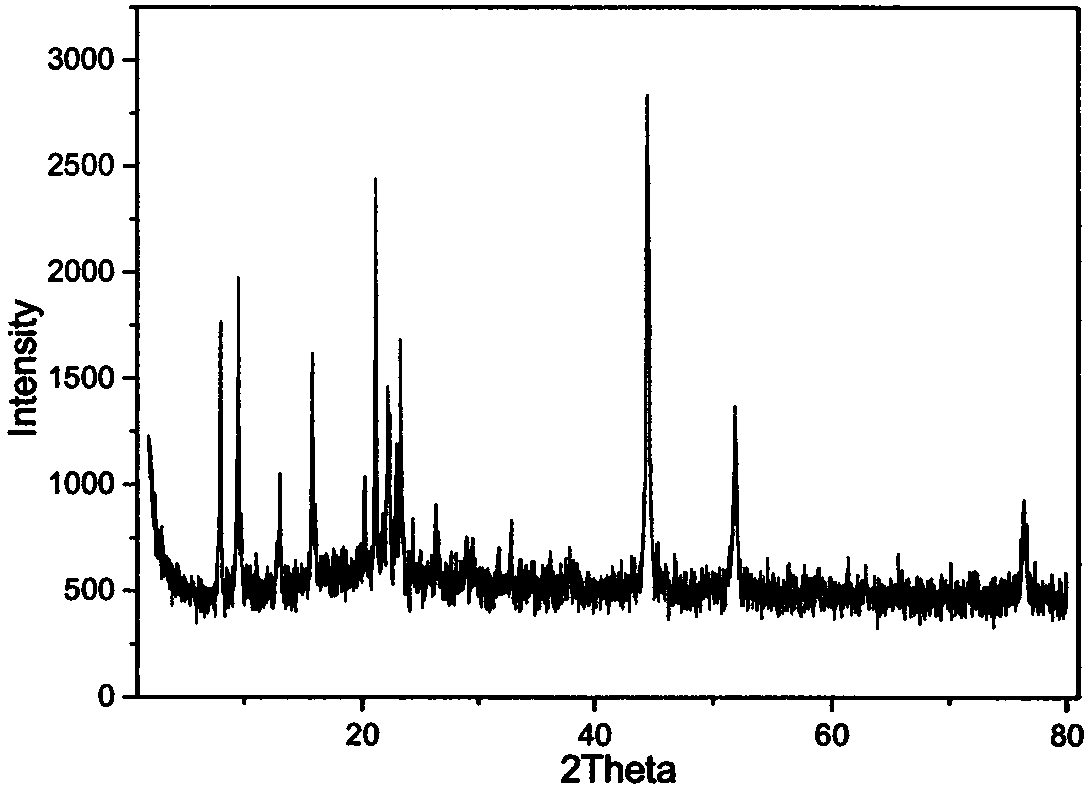

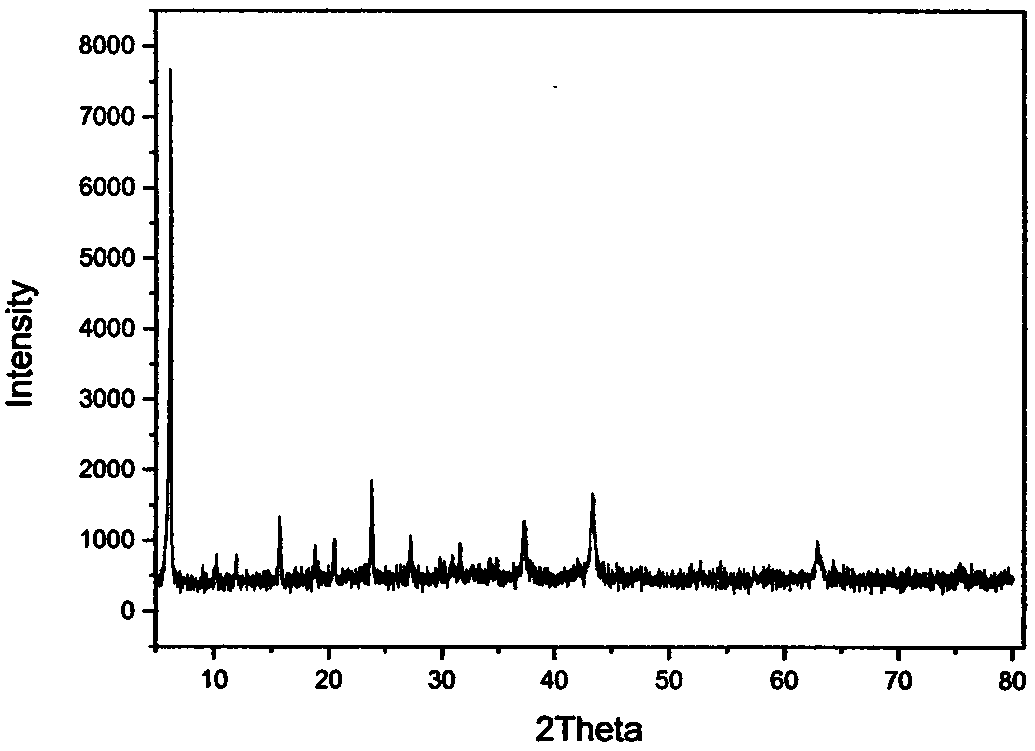

Image

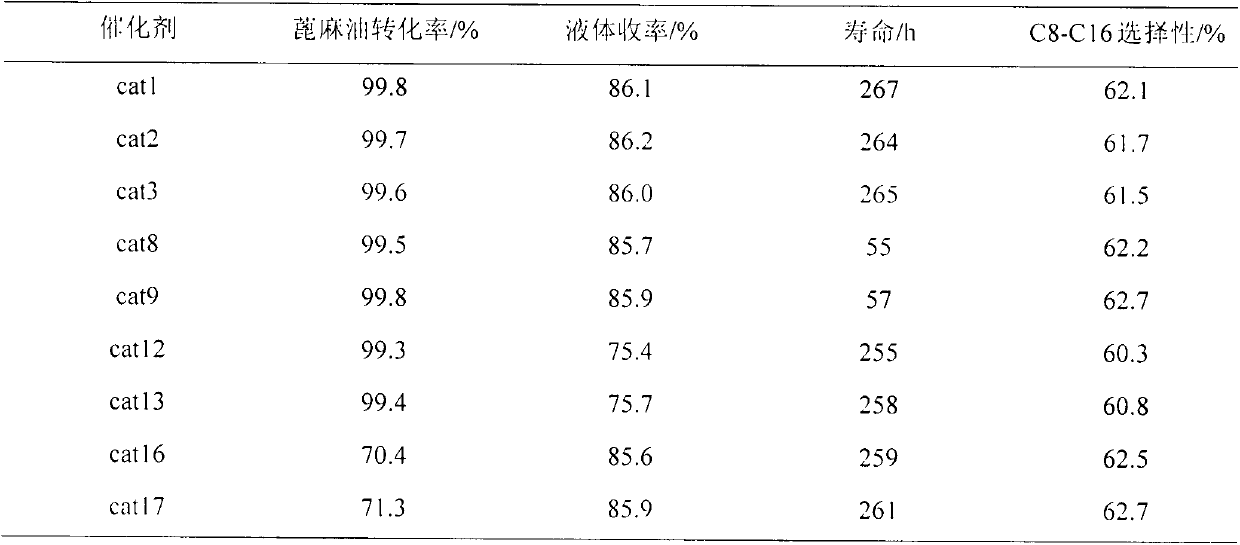

Examples

Embodiment 1

[0045] Embodiment 1, the preparation of hydrodeoxygenation catalyst, comprises the following steps:

[0046] (1) Pretreatment of the carrier: add 10g of MCM-41 to 100g of 5% ethanol solution of 3-aminopropyltriethoxysilane, stir at 60°C for 36h, and then filter the resulting mixture with suction , separated, and then dried the obtained filter cake in an air atmosphere at 120°C, then cooled to room temperature, then added the obtained sample to 100g of an aqueous solution with a mass fraction of 10% citric acid, and stirred at 90°C for 36h, Then the obtained mixture was suction filtered and separated, and then the obtained filter cake was dried at 120°C to obtain sample A;

[0047] (2) Loading of additives: Dissolve 0.47g of ferric nitrate into 45g of deionized water under stirring conditions at 60°C, and stir thoroughly to obtain solution B; then add solution B to 7.0g of sample A, stir for 24h, and then The obtained mixture was dried in an air atmosphere at 120°C, and then c...

Embodiment 2

[0049] Embodiment 2, the preparation of hydrodeoxygenation catalyst, comprises the following steps:

[0050] (1) Pretreatment of the carrier: add 10g of MCM-41 to 100g of 5% ethanol solution of 3-aminopropyltriethoxysilane, stir at 60°C for 36h, and then filter the resulting mixture with suction , separated, and then dried the obtained filter cake in an air atmosphere at 120°C, then cooled to room temperature, then added the obtained sample to 100g of an aqueous solution with a mass fraction of 10% citric acid, and stirred at 90°C for 36h, Then the obtained mixture was suction filtered and separated, and then the obtained filter cake was dried at 120°C to obtain sample A;

[0051] (2) Loading of additives: Dissolve 1.12g of ferric nitrate into 45g of deionized water under stirring at 60°C, and stir thoroughly to obtain solution B; then add solution B to 7.5g of sample A, stir for 24h, and then The obtained mixture was dried in an air atmosphere at 120°C, and then calcined in ...

Embodiment 3

[0053] Embodiment 3, as the preparation of the supported metal phosphide catalyst of hydrodeoxygenation catalyst, comprises the following steps:

[0054] (1) Pretreatment of the carrier: 10g of SBA-15 was added to 100g of 5% ethanol solution of 3-aminopropyltriethoxysilane, stirred at 50°C for 36h, and then the resulting mixture was pumped After filtration and separation, the resulting filter cake was dried in an air atmosphere at 120°C, then cooled to room temperature, and then the obtained sample was added to 100 g of an aqueous solution with a mass fraction of 10% citric acid, and stirred at 90°C for 36 hours , and then the obtained mixture was suction filtered and separated, and then the obtained filter cake was dried at 120°C to obtain sample A;

[0055] (2) Loading of additives: Dissolve 0.86g of ferric nitrate into 45g of deionized water under stirring conditions at 60°C, and stir thoroughly to obtain solution B; then add solution B to 7.5g of sample A, stir for 24h, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com