Precipitated iron catalyst for Fischer-Tropsch synthesis and preparation method thereof

A technology for synthesis of catalysts and catabolites, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, catalysts for physical/chemical processes, etc., can solve problems such as increasing CO2 emissions and wasting raw material CO, and achieves a simple, continuous and economical synthesis process Production cost, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

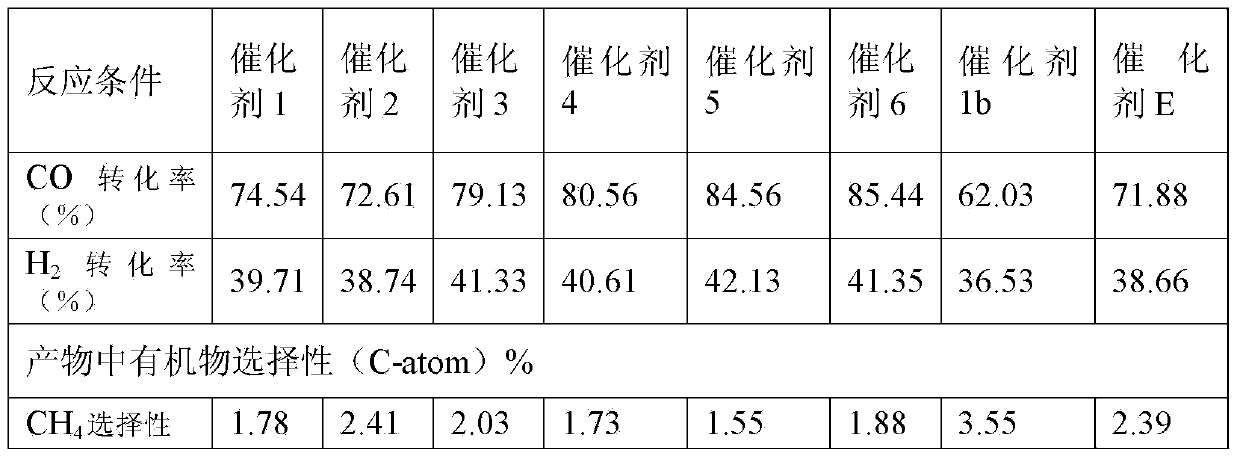

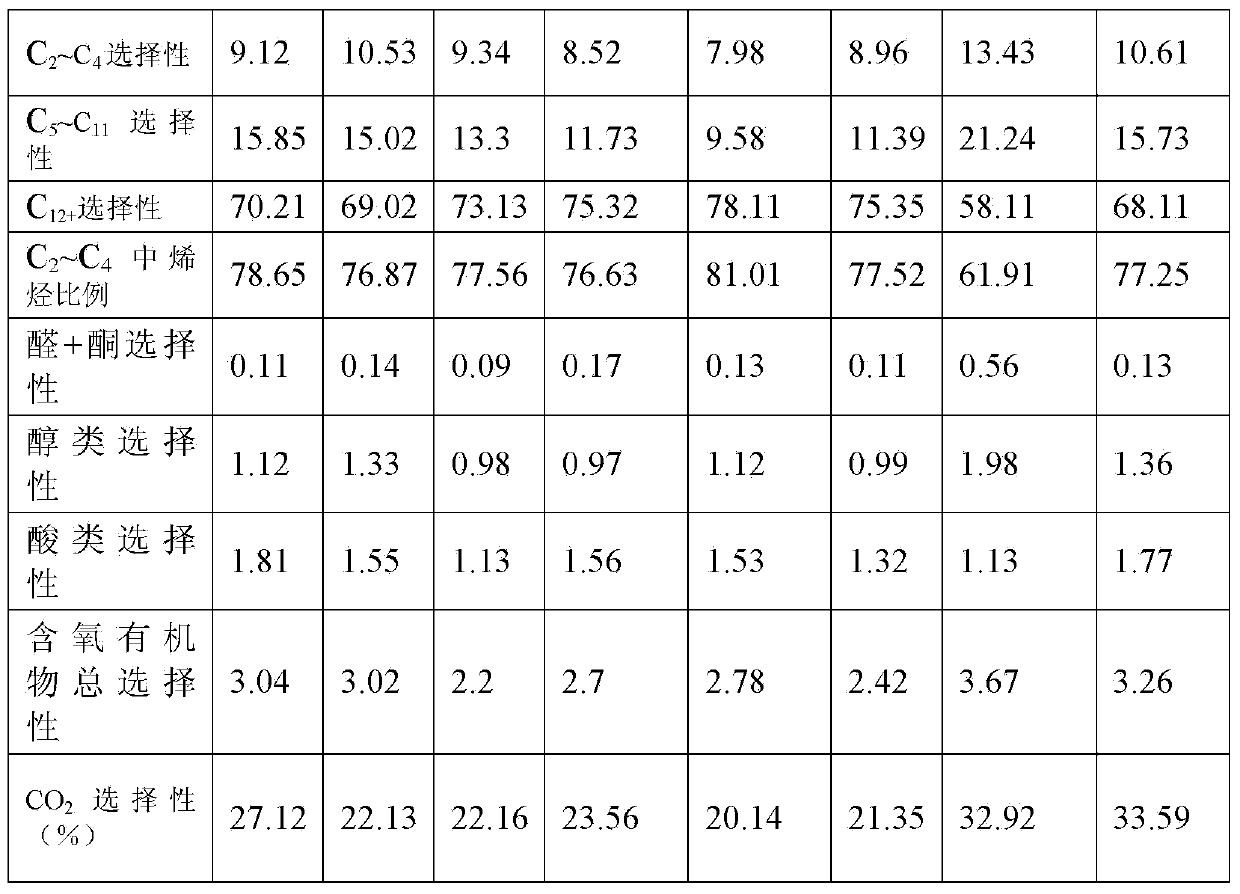

Examples

Embodiment 1

[0032] 1) Weigh 4.04kg of ferric nitrate nonahydrate, then add the corresponding amount of potassium titanium oxalate and copper nitrate, add deionized water to dissolve, so that the weight ratio of each component in the mixed salt solution is Fe:Ti:Cu=100:11.2: 8.5, the concentration of Fe ions in the mixed salt solution is 0.5mol / L.

[0033] Take 2.8 kg of sodium carbonate, add deionized water to dissolve it, and prepare a 2mol / L sodium carbonate solution. Use the sodium carbonate solution as a precipitant and preheat the mixed salt solution to 65°C, and use co-current precipitation to obtain a mixed salt precipitation slurry. During the entire co-current precipitation process, the temperature of the mixed salt precipitation slurry was kept at 65° C., and the pH value was always 7.0.

[0034] 2) The mixed salt precipitation slurry was kept at 65°C for aging for 2 hours, filtered and washed to obtain a catalyst filter cake with a conductivity of the filtrate below 1000 μs / cm....

Embodiment 2

[0038] 1) Weigh 4.04kg of ferric nitrate nonahydrate, then add the corresponding amount of potassium titanium oxalate and copper sulfate, add deionized water to dissolve, so that the weight ratio of each component in the mixed salt solution is Fe:Ti:Cu=100:0.4:1.0 , the concentration of Fe ions in the mixed salt solution is 2mol / L.

[0039] Take 2.8kg of sodium carbonate, add deionized water to dissolve it, and prepare a 0.5mol / L sodium carbonate solution, use the sodium carbonate solution as a precipitant and preheat the mixed salt solution to 40°C, and use co-current precipitation to obtain a mixed salt precipitation slurry . The temperature of the mixed salt precipitation slurry is kept at 40° C. and the pH value is always 10 throughout the co-current precipitation process.

[0040] 2) Keep the mixed salt precipitation slurry at 40°C for aging, filter and wash for 0.1 hour to obtain a catalyst filter cake with a conductivity of the filtrate below 1000 μs / cm.

[0041] 3) A...

Embodiment 3

[0044] 1) Weigh 4.04kg of ferric nitrate nonahydrate, then add the corresponding amount of potassium titanium oxalate and copper nitrate, add deionized water to dissolve, so that the weight ratio of each component in the mixed salt solution is Fe:Ti:Cu=100:1:7 , the concentration of Fe ions in the mixed salt solution is 1.2mol / L.

[0045] Take 2.2kg of sodium carbonate, add deionized water to dissolve and prepare a 1.5mol / L sodium carbonate solution, use the sodium carbonate solution as a precipitating agent and preheat the mixed salt solution to 60°C, and use co-current precipitation to obtain a mixed salt precipitation slurry . The temperature of the mixed salt precipitation slurry is kept at 60° C. and the pH value is always 5.5 throughout the co-current precipitation process.

[0046] 2) Keep the mixed salt precipitation slurry at 30°C for aging for 5 hours, filter and wash to obtain a catalyst filter cake with a conductivity of the filtrate below 1000 μs / cm.

[0047] 3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com