A kind of preparation method of pitch-based activated carbon

An activated carbon and pitch-based technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems affecting the application range, high micropore content, low mesopore content, etc., and achieve excellent electrochemical performance and surface utilization The effect of high rate and high mesopore content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The coal tar pitch is crushed and pulverized, and the powder with a particle size of 100-150 mesh is selected as the raw material. The powder is put into a coking furnace for coking at 1.5°C / min and 480°C, and the coking time is controlled at 9 hours to obtain green coke. Crush raw coke, screen powder with a particle size of 100-200 mesh as raw material, mix KOH and powdered green coke according to the ratio of mass ratio KOH: raw coke = 4:1, and put the mixture into the activation furnace, under the protection of nitrogen The temperature was raised to 700°C at a rate of 5°C / min, and activated by heat preservation for 2 hours. The product was washed with deionized water and dilute hydrochloric acid until neutral, dehydrated, dried, and pulverized to obtain activated carbon.

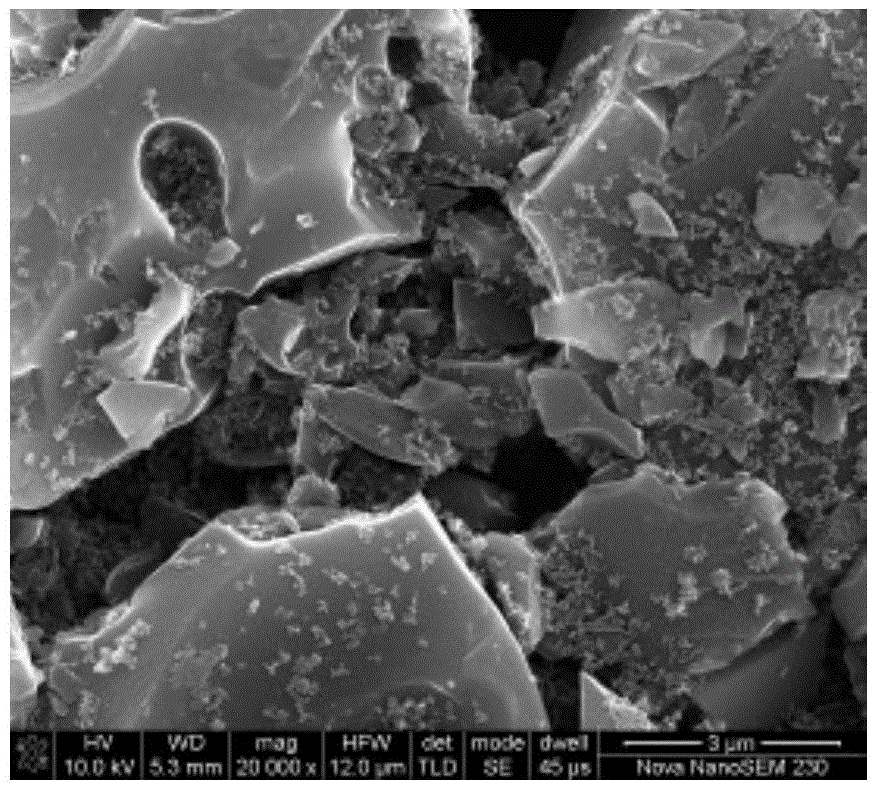

[0029] as table 1 and figure 1 SEM image of activated carbon. Total pore volume (V t ) is 1.18mL / g, in which the micropore volume (V micro ) is 0.73mL / g, the ratio of micropore volume to total p...

Embodiment 2

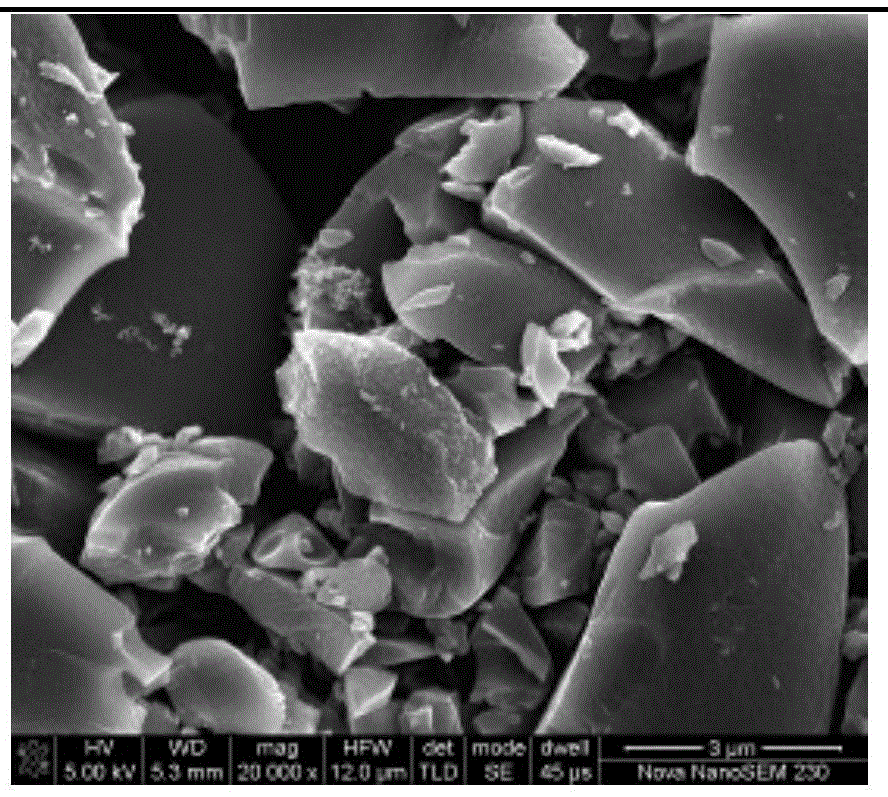

[0034] The coal tar pitch is crushed and pulverized, and the powder with a particle size of 90-120 mesh is selected as the raw material. The powder is put into a coking furnace for coking at 1.5°C / min and 460°C, and the coking time is controlled at 9 hours to obtain green coke. Crush raw coke, screen powder with a particle size of 100-200 mesh as raw material, mix KOH and powdered green coke according to the ratio of mass ratio KOH: raw coke = 4:1, and put the mixture into the activation furnace, under the protection of nitrogen The temperature was raised to 800°C at a rate of 5°C / min, and activated by heat preservation for 2 hours. The product was washed with deionized water and dilute hydrochloric acid until neutral, dehydrated, dried, and pulverized to obtain activated carbon. as table 2 and image 3 SEM image of activated carbon, total pore volume (V t ) is 1.42mL / g, in which the micropore volume (V micro ) is 0.79mL / g, the ratio of micropore volume to total pore volume ...

Embodiment 3

[0040] The coal tar pitch is crushed and pulverized, and the powder with a particle size of 90-120 mesh is selected as the raw material. The powder is put into a coking furnace for coking at 0.5°C / min and 440°C, and the coking time is controlled at 7 hours to obtain green coke. Grind raw coke, screen powder with a particle size of 100-200 mesh as raw material, mix KOH and powdered raw coke according to the ratio of mass ratio KOH: raw coke = 2:1, put the mixture into the activation furnace, and protect it under nitrogen The temperature was raised to 900°C at a rate of 1°C / min, and activated by heat preservation for 2 hours. The product was washed with deionized water and dilute hydrochloric acid until neutral, dehydrated, dried, and pulverized to obtain activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com