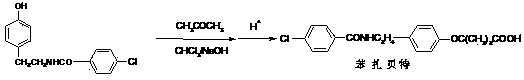

Purification method of bezafibrate in preparation process

A technology for the preparation of bezafibrate, which is applied in the field of purification during the preparation of bezafibrate, can solve problems such as product loss, and achieve the effect of increasing product content and avoiding product loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: Add 4 g of N-p-hydroxyphenylethyl-4-chlorobenzamide, 6 g of sodium hydroxide and 32 ml of acetone to the reaction flask, install a reflux condenser, a mechanical stirring device, and a dropper on the reaction flask Funnel and thermometer, stir at 20°C for 0.5h, add 6g of chloroform dropwise, control the temperature at 30°C, react at this temperature for 1h, then raise the temperature and reflux for 1h; cool to room temperature, add water to the reactant until it becomes clear, add dropwise under stirring Adjust the pH to 11 with 15% hydrochloric acid in mass concentration, pass carbon dioxide gas into the solution until no more precipitates appear, filter to remove the precipitates, continue to add 15% hydrochloric acid in the filtrate to pH 3, and precipitate a white solid, continue to stir for 1 hour Suction filtration, the filter cake was washed and dried to obtain 5 g of beige powder. The yield is 95%, and the content analyzed by high performance liqui...

Embodiment 2

[0013] Embodiment 2: Add 10 g of N-p-hydroxyphenylethyl-4-chlorobenzamide, 30 g of sodium hydroxide and 150 ml of acetone into the reaction flask, install a reflux condenser, a mechanical stirring device, and a dripping solution on the reaction flask Funnel and thermometer, stir at 40°C for 1h, add 25g of chloroform dropwise, react at this temperature for 1h, then raise the temperature and reflux for 2h; cool to room temperature, add water to the reactant until it becomes clear, add dropwise 15% hydrochloric acid under stirring to adjust the pH To 11, pass carbon dioxide gas into the solution until there is no more precipitate, filter to remove the precipitate, continue to dropwise add 15% hydrochloric acid to the filtrate to pH 4, and precipitate a white solid, continue to stir for 1 hour, then suction filter, and wash the filter cake After drying, 12.3 g of beige powder was obtained. The yield was 94%, and the content analyzed by high performance liquid chromatography was 98...

Embodiment 3

[0014] Embodiment 3: Add 25g of N-p-hydroxyphenylethyl-4-chlorobenzamide, 62.5g of sodium hydroxide and 375 ml of acetone to the reaction flask, install a reflux condenser, a mechanical stirring device, drop liquid funnel and thermometer, stirred at 30°C for 45 min, added dropwise 50g of chloroform, controlled the temperature at 35°C, reacted at this temperature for 1h, then raised the temperature and refluxed for 1.5h; cooled to room temperature, added water to the reactant until clear, stirred Add dropwise 15% hydrochloric acid to adjust the pH to 11, pass carbon dioxide gas into the solution until no precipitation occurs, filter to remove the precipitate, continue to dropwise add 15% hydrochloric acid to the filtrate to pH 3.5, and precipitate a white solid. Continue to stir for 1 hour, then filter with suction, wash and dry the filter cake to obtain 31 g of beige powder. The yield was 94.5%, and the content analyzed by high performance liquid chromatography was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com