Method for leaching metallic copper in copper pyrites by using amino acid reinforced microorganisms

A microbial leaching and chalcopyrite technology, which is applied in the field of mining and metallurgy technology and the field of microorganisms, can solve the problems of large-scale industrialization of chalcopyrite with low leaching rate, and achieve the effects of accelerating electron transfer, improving methods, and being easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

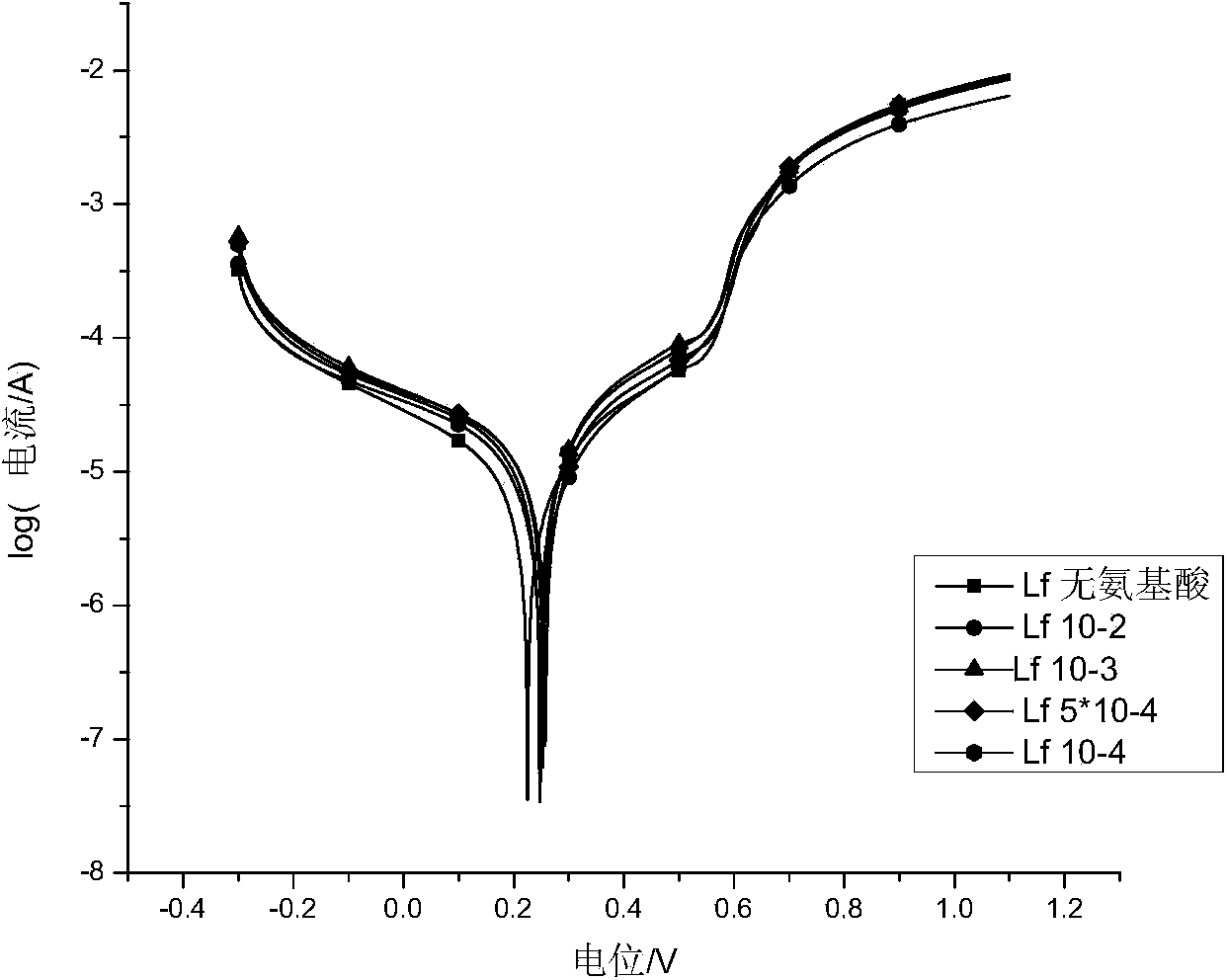

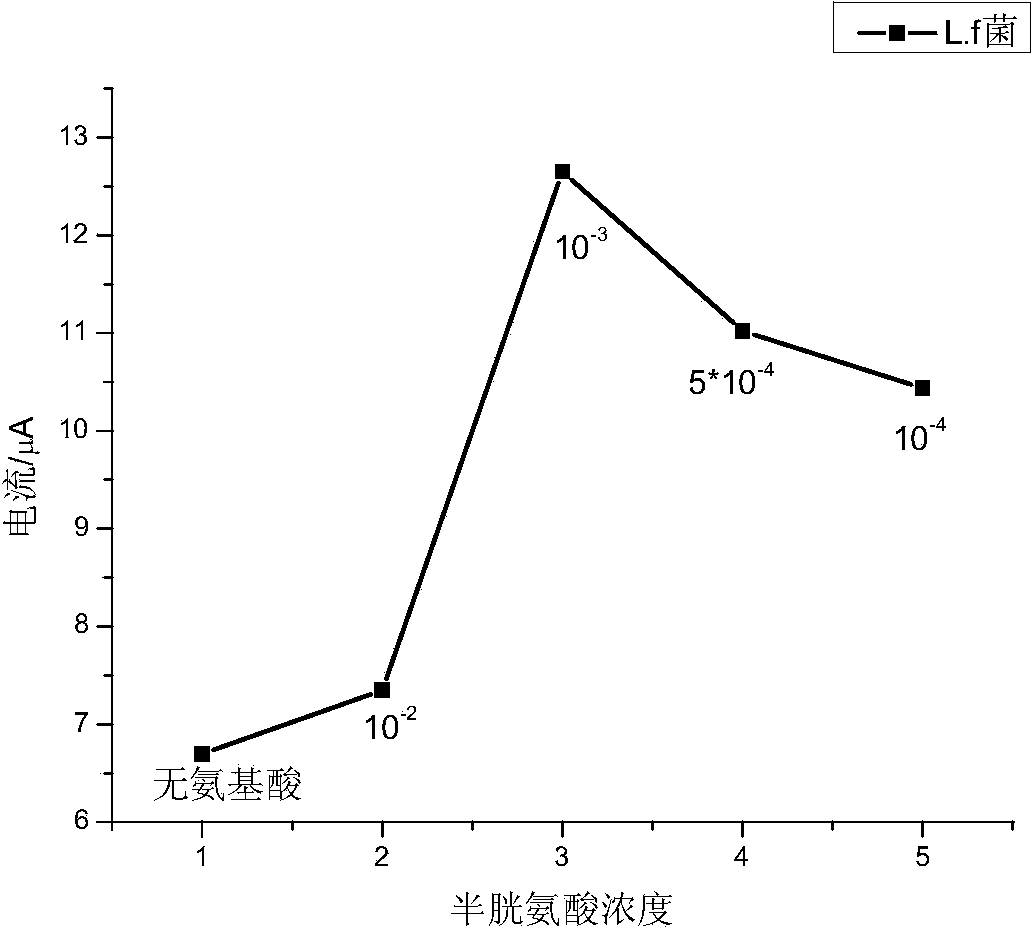

[0043] Cysteine strengthens the leaching of chalcopyrite by L.f (Leptospirillum ferrooxidans) bacteria, comprising the following steps:

[0044] (1) Culture of bacteria

[0045] That is to use 9k medium (with iron): ammonium sulfate 3g / L, potassium sulfide 0.1g / L, magnesium sulfate, heptahydrate 0.5g / L, anhydrous dipotassium hydrogen phosphate 0.5g / L, calcium nitrate 0.01g / L , ferrous sulfate heptahydrate 44.3g / L, 2.5mol / L sulfuric acid to adjust the pH to 2.0, inoculate the bacteria with 10% inoculum and cultivate in the TS-200B constant temperature shaker, the culture temperature is 40 ℃, shaker The rotation speed is 180rpm; the cultivation is stopped when the cultivation reaches the logarithmic phase, and the bacterial liquid is centrifuged and collected by using a Heraeus Multifuge X1R refrigerated centrifuge and a F15-6x100y rotor.

[0046] (2), add cysteine chalcopyrite microbial leaching

[0047] Transfer the bacteria collected by centrifugation in step (1) to 9k ...

Embodiment 2

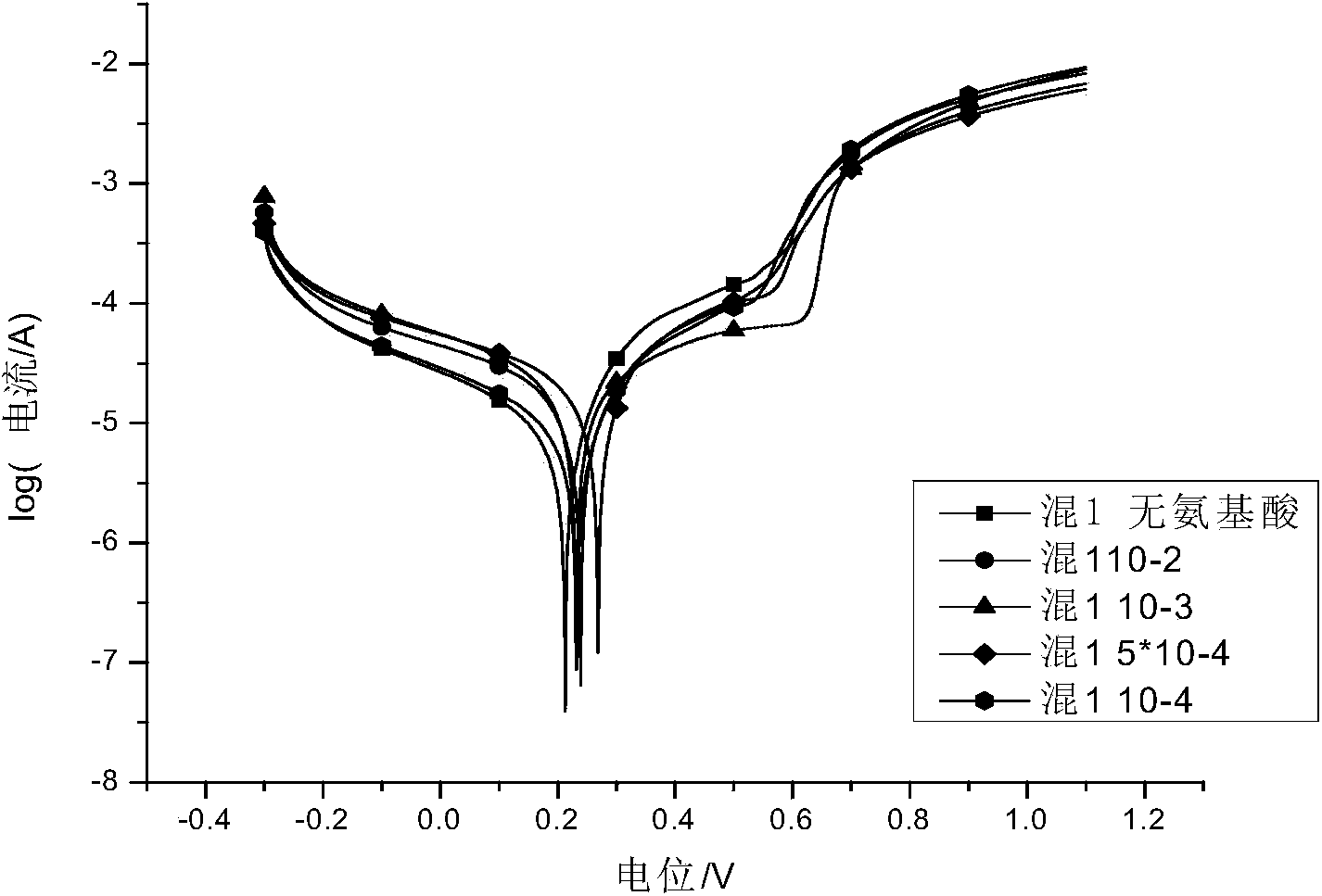

[0052] Cysteine enhanced mixed bacteria (Leptospirillum ferriphilum and Sulfobacillus thermotolerans) leaching chalcopyrite, including the following steps:

[0053] (1), the cultivation of bacteria (with embodiment 1);

[0054] (2), add cysteine chalcopyrite microbial leaching

[0055] The thalline collected by centrifugation in step (1) is transferred to 9k basal medium (iron-free): ammonium sulfate 3g / L, potassium sulfide 0.1g / L, magnesium sulfate, heptahydrate 0.5g / L, anhydrous hydrogen phosphate Dipotassium 0.5g / L, calcium nitrate 0.01g / L, 2.5mol / L sulfuric acid to adjust the pH to 2.0, and dilute to 108 bacteria / ml; then add cysteine, the concentration of cysteine is respectively 0mol / L, 10 -2 mol / L, 10 -3 mol / L, 5×10 -4 mol / L, 10 -4 mol / L; Clean the self-made chalcopyrite working electrode with absolute ethanol, put it into the above bacterial solution, and soak for 12 hours.

[0056] The self-made chalcopyrite electrode was soaked for 12 hours before electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com