Eddy current retarder device based on magnetorheological effect

A technology of eddy current retarder and magneto-rheological effect, which is applied in the fields of electric vehicles, transportation and packaging, and brake types, etc., can solve the problems of difficult excitation device, high manufacturing precision, and complex structure, etc., and can improve the braking torque. controllability, improve low-speed braking performance, and reduce braking response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

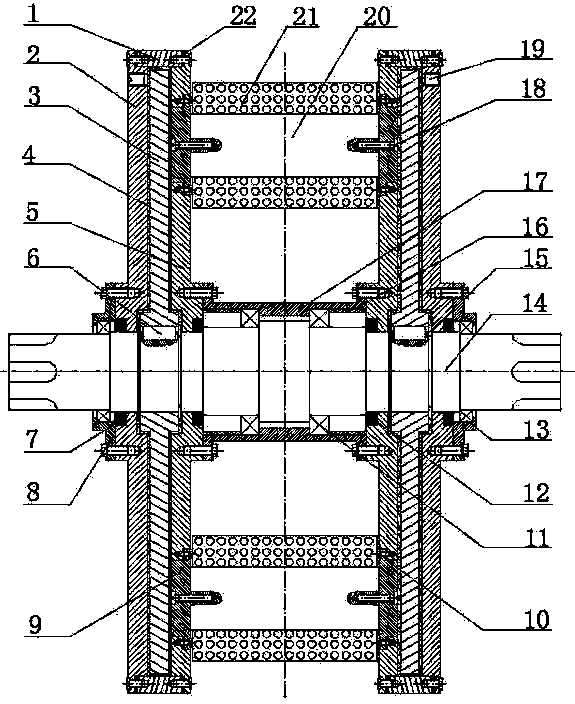

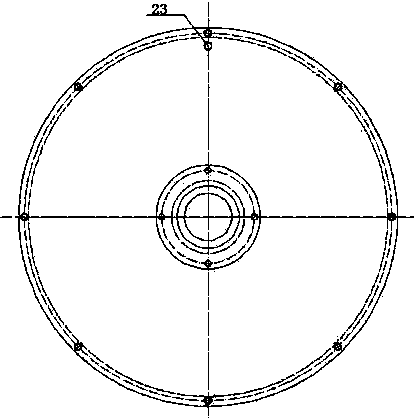

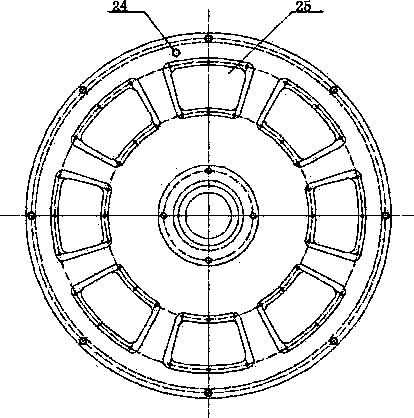

[0030] like figure 1 As shown, the present invention is a symmetrical structure with a central stator assembly and double rotors on both sides, including a cylindrical shell 1 (2 pieces), an outer shell 2 (2 pieces), a rotor disk 3 (2 pieces), a magnetic Rheological fluid 4, inner housing 5 (2 pcs), ordinary flat key 6 (2 pcs), outer lip seal ring 7 (2 pcs), bearing cover 8 (2 pcs), pole shoe 9 (16 pcs), Sector seal ring 10 (4 pcs), inner bearing 11 (2 pcs), inner lip seal ring 12 (2 pcs); outer bearing 13 (2 pcs), drive shaft 14, spring circlip 15 (4 pcs), sleeve Barrel 16 (2 pcs), bearing sleeve 17, countersunk head screw 18 (16 pcs), slotted flat end set screw 19 (4 pcs), magnetic core 20 (8 pcs), excitation coil 21 (8 pcs), seal Washers 22 (4 pcs). Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com