Herbicide composition containing flazasulfuron and use of herbicide composition

A technology for fisasulfuron-methyl and a composition is applied in the field of herbicidal compositions containing fisasulfuron-methyl, which can solve the problems of improper selection of medicines, waste of manpower, inability to weed-killing effect, inadequate use technology, etc., and achieves reduction of use cost, Good weeding effect and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

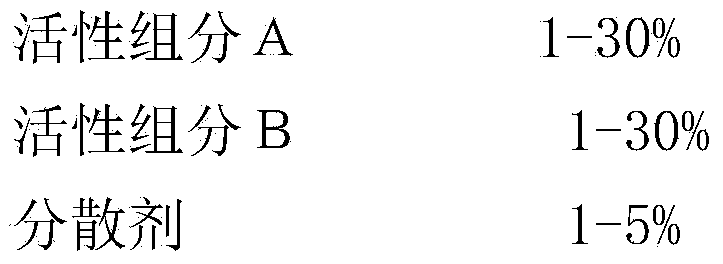

Method used

Image

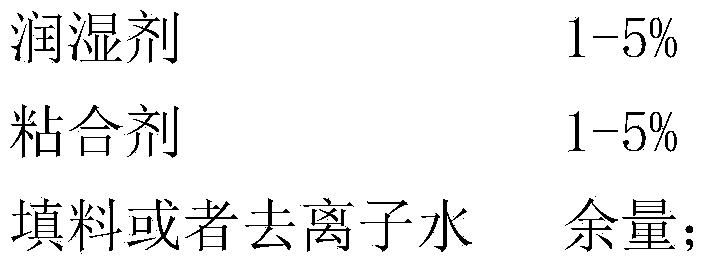

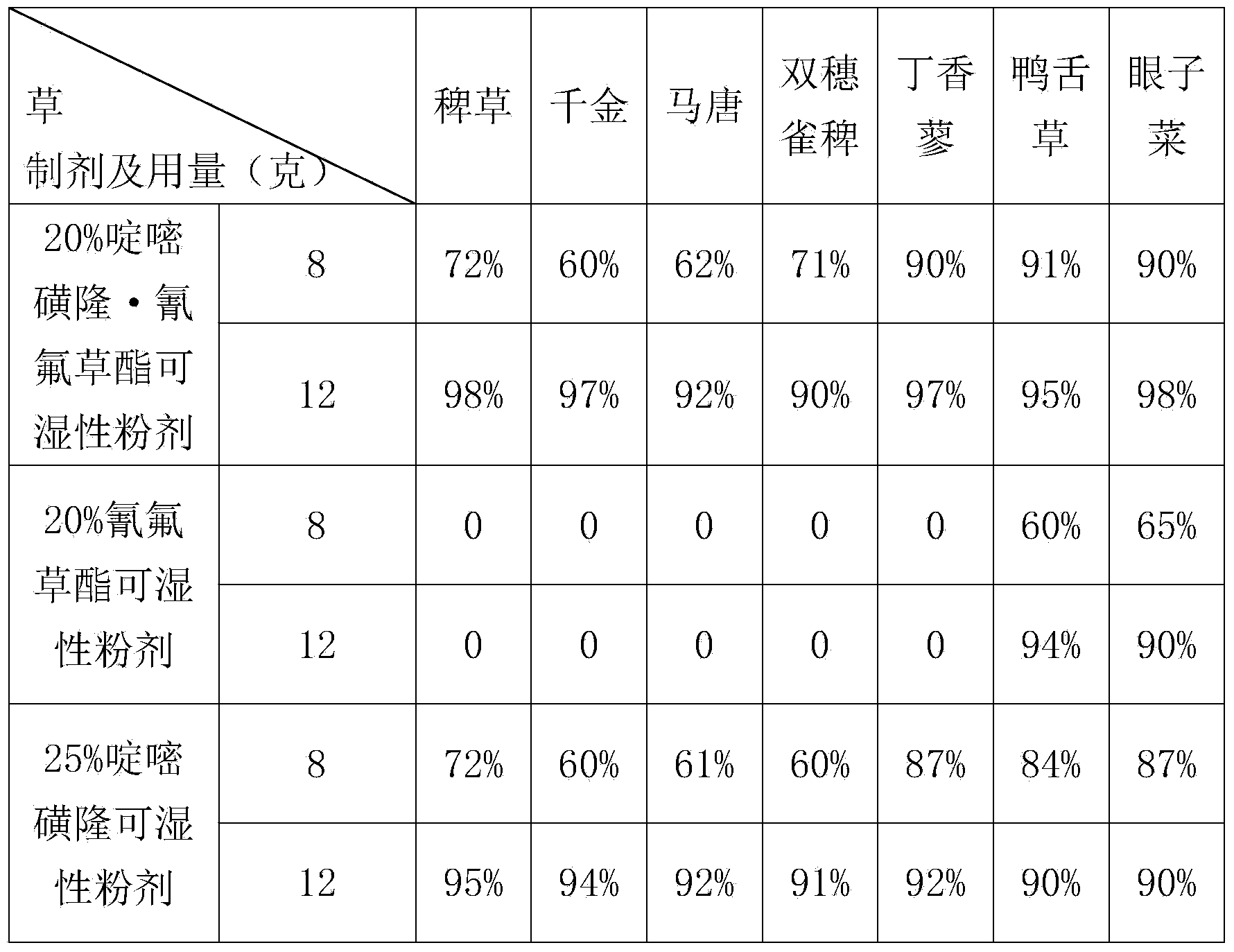

Examples

Embodiment 1

[0027] Process the solid raw drug sulfasulfuron-methyl to 1000 mesh by means of jet crushing, accurately weigh 15% sulfasulfuron-methyl, 5% cyhalofop-methyl in active component B, dispersant alkylnaphthalene formaldehyde Condensate sulfonate 6%, wetting agent alkyl naphthalene sulfonate 4%, adhesive alkyl aryl polyoxyethyl ether 5%, the rest is filler kaolin, fully mixed evenly after replenishing, and finally passed quality inspection After each technical index is qualified, it can be packaged as 20% rimsulfuron-cyhalofop-ethyl wettable powder.

Embodiment 2

[0029] With the method of airflow pulverization, the solid raw drug flusulfuron-methyl is processed to 2000 mesh, and according to weight percentage, take flurimsulfuron-methyl 15%, quinclorac 5%, dispersant alkylnaphthalene formaldehyde condensate sulfonate 4 %, wetting agent alkyl naphthalene sulfonate 4%, binder alkyl aryl polyoxyethyl ether 5%, deionized water is added to 100% for initial mixing, shear stirring, dispersion, and is prepared into a slurry Afterwards, grind for 2 hours through a horizontal sand mill to make the particle size 1 micron, and then it can be configured into a flowable 20% rimsulfuron-quinclorac suspension preparation.

Embodiment 3

[0031] Process the solid raw drugs oxadiazone and sulfadiazone to 3000 mesh by means of jet crushing, and accurately weigh 15% oxadiazone, 5% oxadiazone, dispersant alkylnaphthalene formaldehyde condensate according to weight percentage Sulfonate 6%, wetting agent alkylnaphthalene sulfonate 4%, binder alkyl aryl polyoxyethyl ether 5%, filler kaolin 12% and the rest of water are fully mixed and stirred to form a plastic material. Extrusion granulation, drying, sieving, and finally after passing the quality inspection of various technical indicators, it can be packaged into 20% sulfasulfuron-oxadiazone water-dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com