Sausage containing crosslinked peanut protein and preparation method thereof

A peanut protein and sausage technology, applied in the field of sausage containing cross-linked peanut protein and its preparation, can solve the problems of underutilization of peanut protein, lack of emulsification, water and oil retention, lack of development and utilization, etc., and achieve Solve the effect of continuous price rise, improve taste and quality, and excellent taste and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

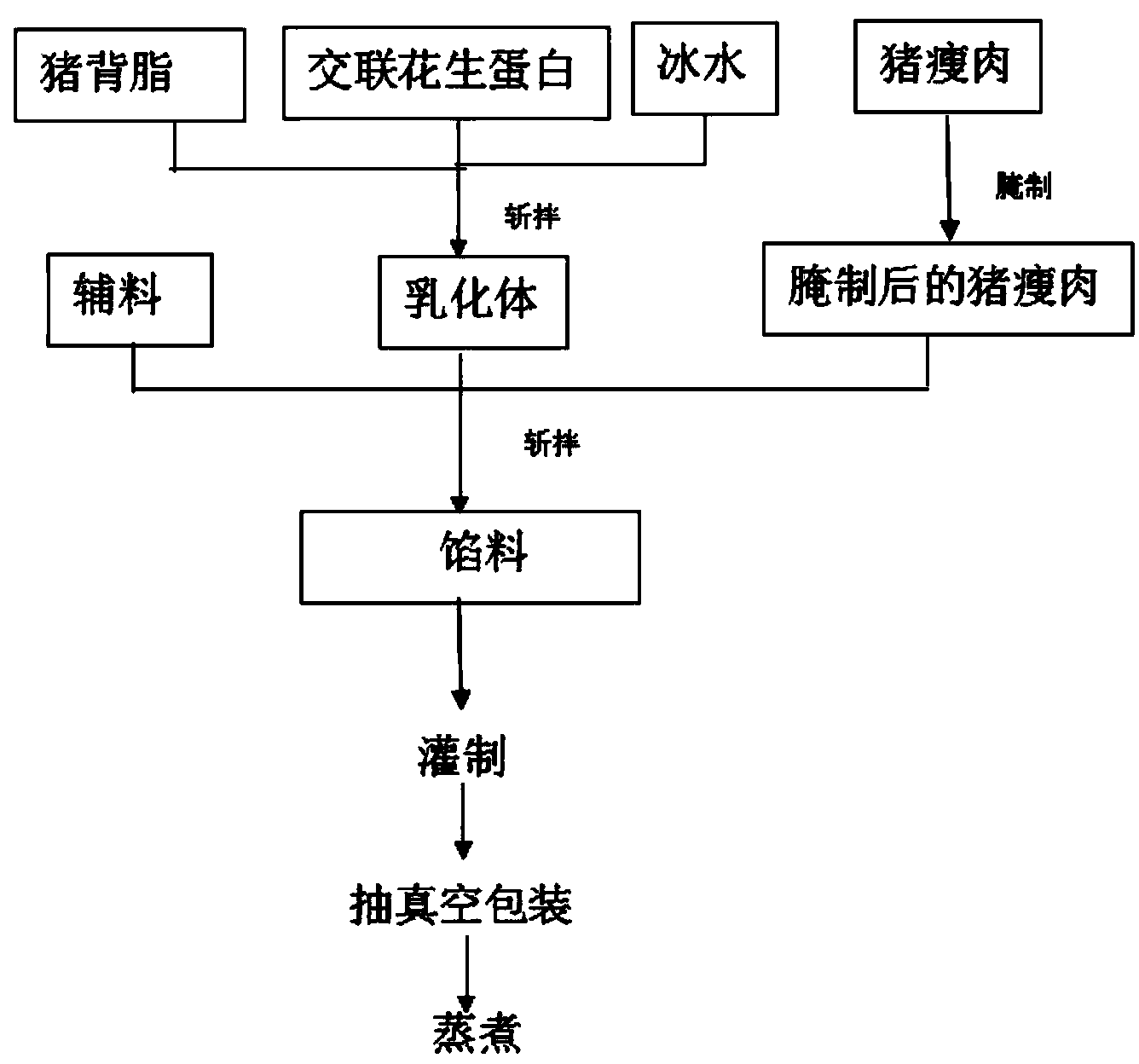

[0043] The preparation method of sausage containing cross-linked peanut protein includes the following steps:

[0044] Step 1. Prepare the cross-linked peanut protein, extract the peanut protein components, add the cross-linking enzyme to carry out the cross-linking reaction, and obtain the corresponding cross-linked peanut protein; in the present invention, the peanut globulin and the concomitant balls in the peanut meal are extracted by the cold precipitation method For protein, transglutaminase is added under certain conditions for cross-linking reaction to obtain cross-linked peanut protein.

[0045] Step 2: Preparation of emulsified body. The cross-linked peanut protein, pork back fat and ice water are mixed and chopped to obtain an emulsified body. In the present invention, the cross-linked peanut protein and 1 / 2 of the total amount of ice water can be mixed in the chopper, and then the pork back fat processed into small pieces of about 1 cm2 is added and the chopping is cont...

specific Embodiment 1

[0051] Select qualified 200g fresh pork lean meat and 150g pork back fat, remove the bones and fascia from the lean meat, spread it on the table, and cut both the lean pork and pork back fat into 1cm 2 For the small pieces around, mix 10g of lean meat with salt and marinate for 20h at 4°C. Mix 50g of cross-linked peanut globulin and 150g of ice water in the chopper, add it and process it into 1cm 2 Stir the left and right small pieces of pork back fat for 3min, add 3g sodium tripolyphosphate and 2g sodium pyrophosphate, chop for 2min, then add 5g white pepper powder, 100g corn starch, 80g egg liquid, 15 chicken essence, 0.3g erythorbic acid Sodium and 150g ice water, chop and mix until the meat filling is delicate, viscous and even, chop and mix for 5 minutes, while keeping the temperature of the meat filling ≤10℃ at any time during the chopping process.

[0052] Put the chopped meat into the sausage stuffer and fill it with collagen casings, knotting every 15cm. After filling th...

specific Embodiment 2

[0053] Select qualified 250g fresh pork lean meat and 100g pork back fat, remove the broken bones, fascia, and connective tissue from the lean meat, mix it with 15g salt lean meat, and marinate at 4℃ for 24h. Mix 75g of cross-linked peanut globulin and 160g of ice water in the chopper, and add it to 1cm. 2 Left and right small pieces of pork back fat, stir for 5min, add 2g sodium tripolyphosphate, 3g sodium pyrophosphate and 1g sodium hexametaphosphate, chop for 3min, then add 5g white pepper powder, 120g corn starch, 100g egg liquid, 10g chicken essence, 0.4g sodium erythorbate and 160g ice water, chop and mix until the meat filling is delicate, viscous and even, chop and mix for 6 minutes, while keeping the temperature of the meat filling ≤10℃ at any time during the chopping process.

[0054] Put the chopped fillings into the sausage stuffer and fill them with collagen casings, knotting every 12cm. After filling the sausage, wipe its surface dry, use a 10cm*15cm food-grade vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com