Processing method of all metal channel microstructure with great thickness and high depth-to-width ratio

A technology with high aspect ratio and processing method, applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of long etching time, difficult control of ion beam, microstructure damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

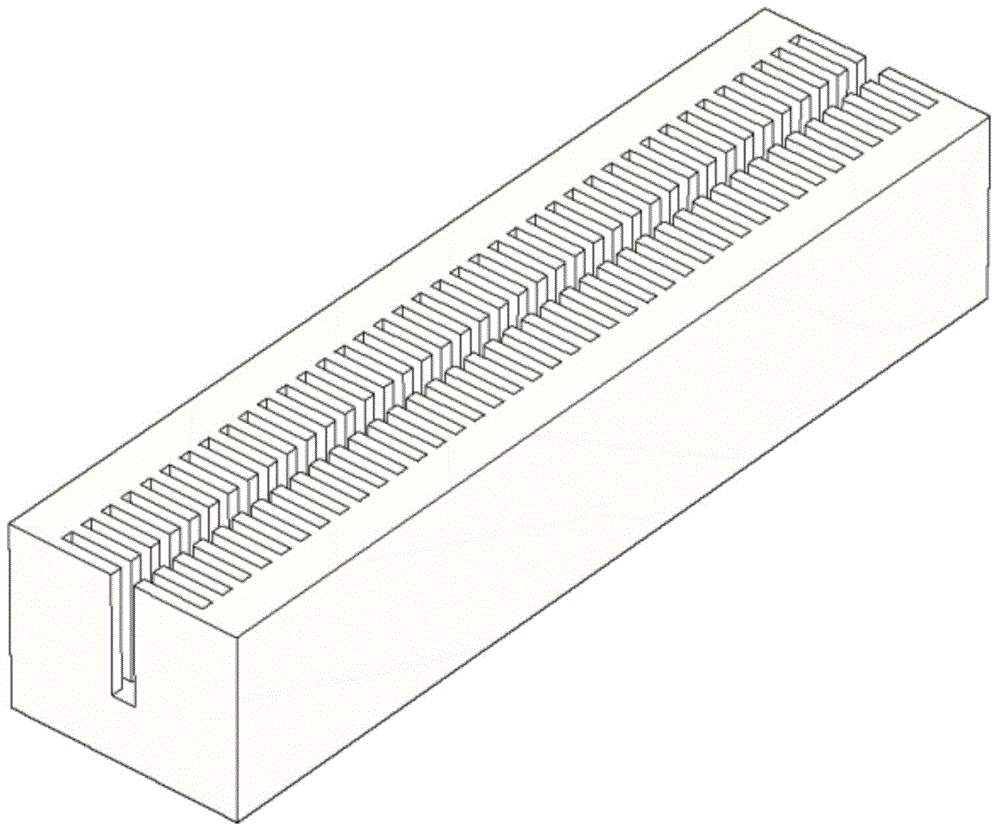

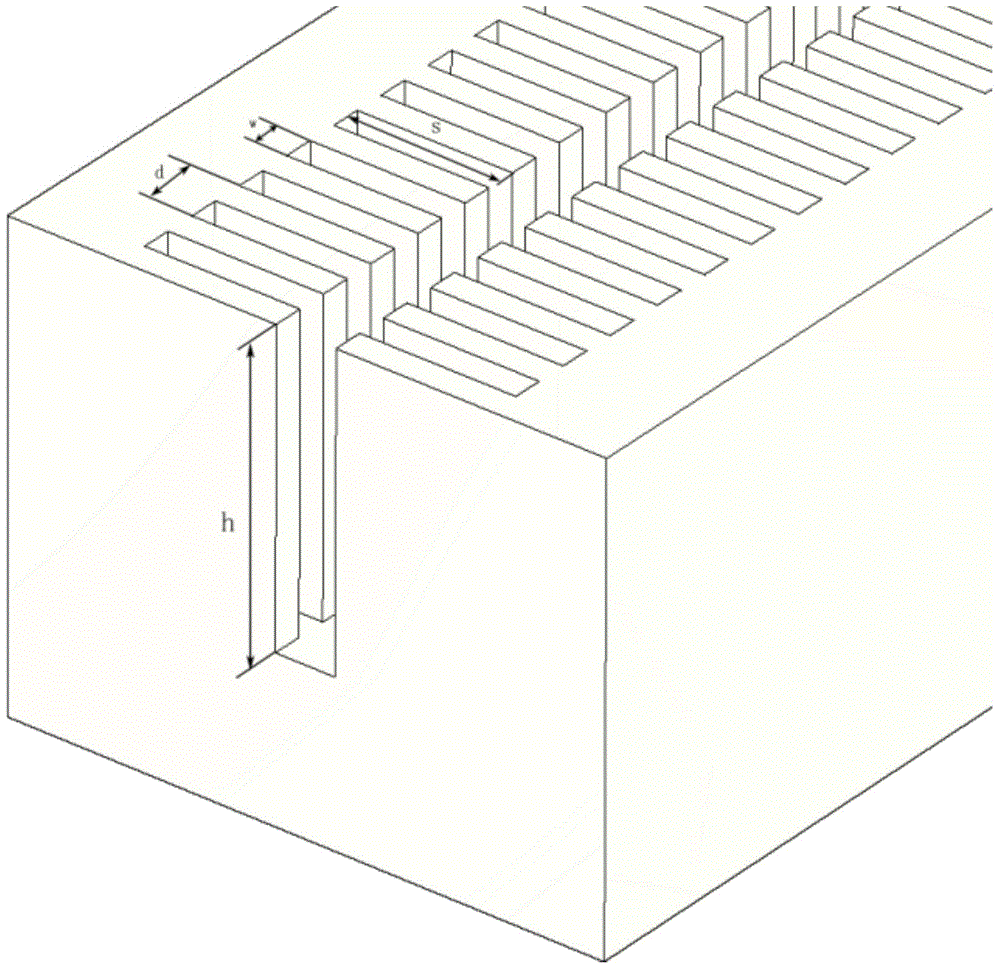

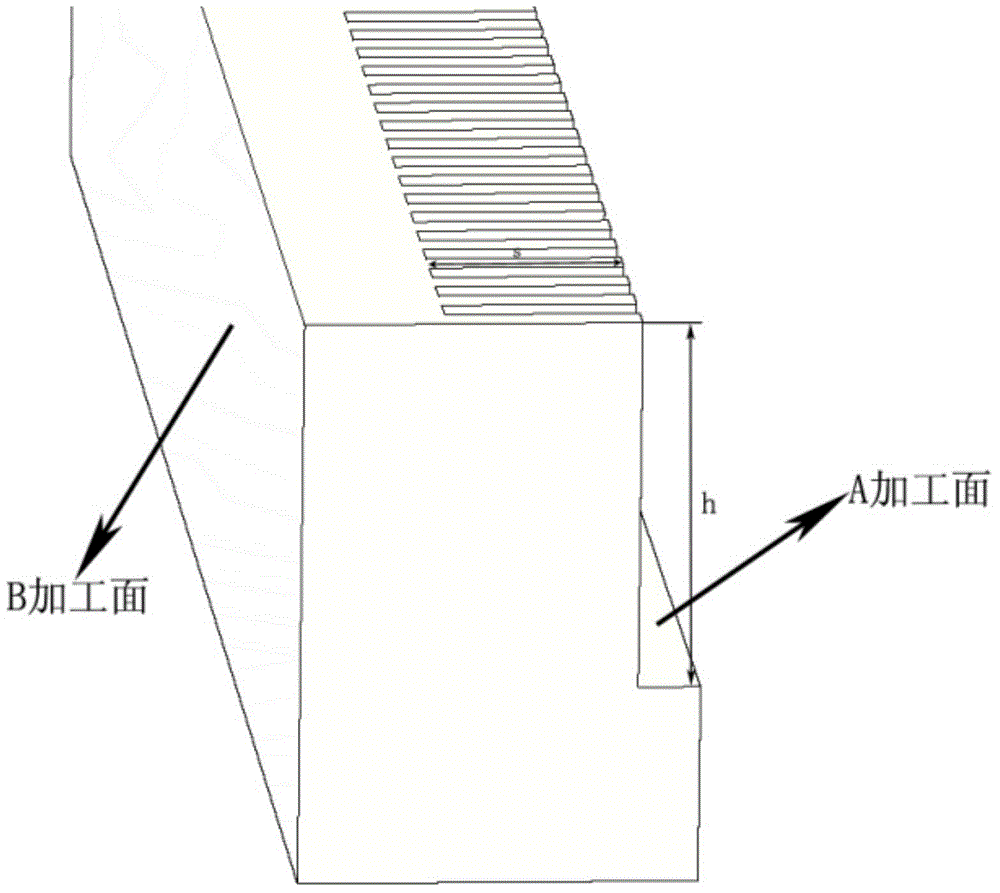

[0029] Such as Figure 1-7 , A method for processing a large-thickness, high-aspect-ratio all-metal trench microstructure, specifically including the following steps:

[0030] (1) Preparation of the substrate, punching, gluing, and preparation of the mask: According to the structural requirements, process the copper substrate of the set size, and process the positioning pin holes at the same position on the different copper sheets; before preparation ,Using ultrasonic cleaning and plasma cleaning to treat the surface of the copper substrate to optimize the cleanliness and surface energy of the substrate surface.

[0031] (2) Ultraviolet lithography: The process of ultraviolet lithography includes spin coating, pre-baking, exposure, post-baking, development and vertical film. The micro electroforming master mold of the single grating is prepared through the above process.

[0032] (3) Micro-electroforming and degumming molding: Put the previously prepared electroforming master mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com